Even the best mechanical watches need to be serviced

A mechanical watch is often compared to a car. However, it is subjected to much more stress than any car. No car, not even a racing car engine, is in constant motion like a mechanical movement. With mechanical movements, wear and tear occurs over time due to dirt, abrasion and a lack of lubricants, but the wearing habits of users and environmental influences also affect watches. The speed of this natural aging process depends largely on how frequently the watch is worn. Regular use exposes it to various environmental factors, including sunlight, temperature fluctuations, and the mechanical stress generated by wrist movements.

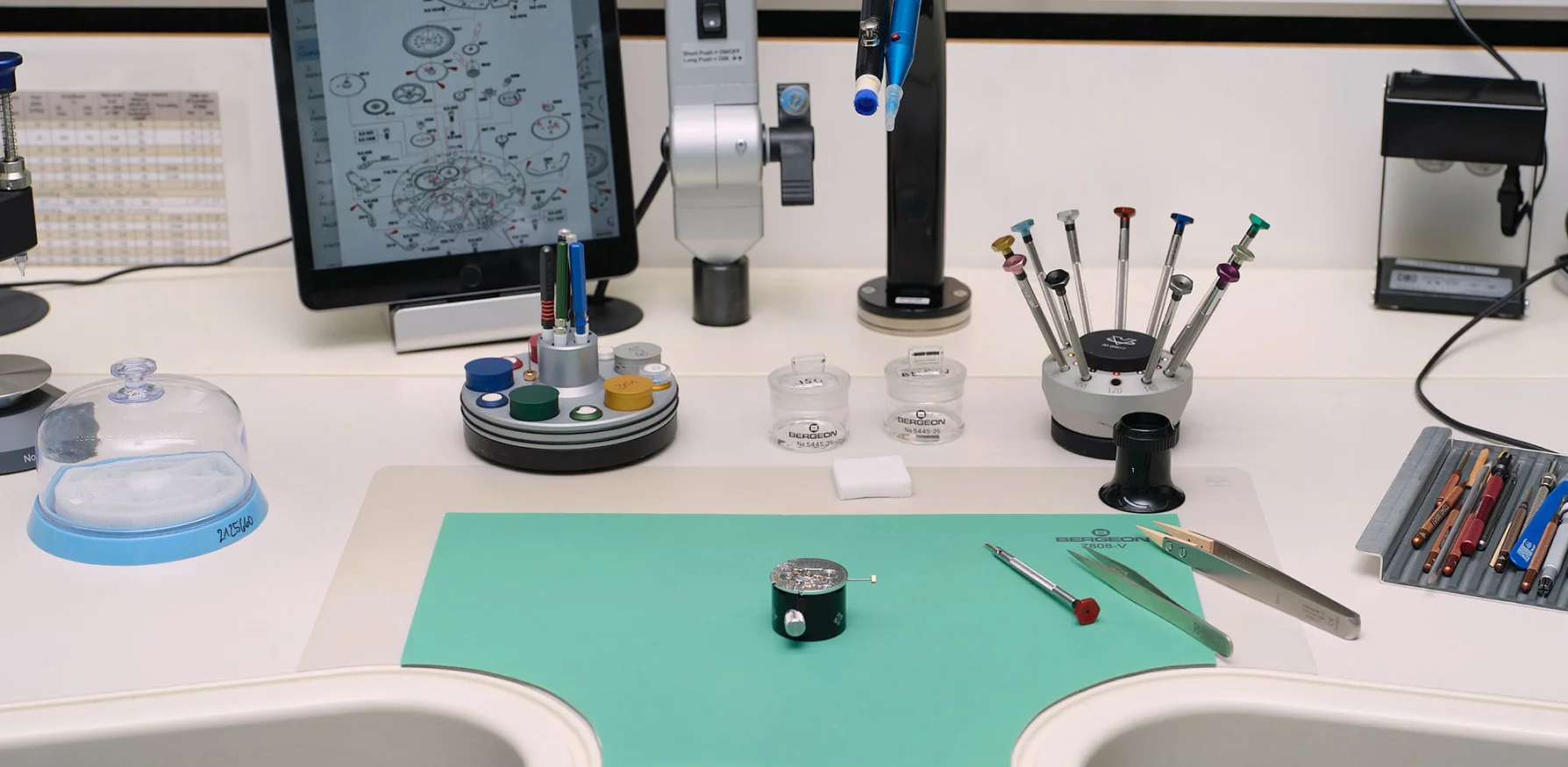

The Patek Philippe service centre in Munich

One of the most modern workshops in Europe

On the third floor of the building in Munich’s renowned Brienner Strasse near Odeonsplatz, a total of 38 employees work in Patek Philippe customer service, including 19 watchmakers and other specialised craftsmen.

Clean room conditions

The 310 square metre studio works under clean room conditions with computer-controlled filter systems and constant air exchange. The temperature is kept at a constant 23 degrees Celsius with a humidity of 45 percent. All employees wear overshoes and protective clothing. Entry to the workshop is only possible via an airlock with negative pressure. The workshop is slightly pressurised. This keeps unwanted particles such as dust and fluff outside. For professionals: the workshop is designed in accordance with ISO standard 8 for dust-free working.

Over 2,200 services per year

The atelier carries out over 2,200 services on watches every year, around half of which are from other European countries. These include watches from the Grandes Complications collection, such as minute repeaters and tourbillons, as well as restorations of vintage watches manufactured before 1972. These are forwarded directly to the manufacture in Geneva.

Restorations of historical models are carried out exclusively in Geneva

In contrast to most service orders, vintage watches are restored in Geneva. The primary goal of every restoration is to preserve the original technical and aesthetic condition of the timepiece. Due to the complexity, the rarity of the object and the watchmaking skills required, a restoration process can take up to two years. Minute repeaters, tourbillons and other rare Grand Complications watches are serviced in the same department in which they were manufactured.

Where can I get my Patek Philippe serviced in Germany?

Here you can find your nearest Patek Philippe authorised dealer in Germany

The majority of watches are repaired in Munich

Almost every Patek Phillippe can be repaired in Munich. Only watches created prior to 1972 and very rare pieces such as tourbillons or minute repeaters are sent directly to the workshops in Geneva. Very complex galvanic processes are also not carried out in Munich. Incidentally, the movement and case are serviced separately. Movements are cleaned in the watch workshop, while the cases are cleaned in the case technology department. At the end, a very strict quality control is carried out.

In general: your Patek Philippe should be serviced regularly

The current Patek Philippe models are supplied with a five-year guarantee, after which a first service is recommended. To make a comparison with cars: servicing a mechanical watch is not simply a matter of changing the oil. At Patek Philippe, watch servicing means that the watch is disassembled down to the smallest detail, all parts are checked, cleaned and replaced if damaged. A master watchmaker then reassembles the watch. A watch service therefore always includes the entire watch and not just a few parts, as is the case with a car.

Why you should take your valuable Patek Philippe directly to your authorised dealer for servicing

You should always opt for professional servicing. The best way to do this is to contact your authorised dealer.

How long does the servicing of a Patek Philippe take?

The complete servicing of a Patek Philippe watch can take 6 to 10 weeks. The length of time depends on the model, the complexity of the movement and the number of specialists required to carry out the work.

What does the servicing of a Patek Philippe cost?

Prices vary depending on the reference. Patek Philippe has simplified the entire cost estimate procedure for the benefit of the customer. The customer brings their watch to a Patek Philippe concessionaire. After identifying the model, the concessionaire prepares a cost estimate for the repair on site.

Rest assured: an Immediate Estimate from Patek Philippe

Patek Philippe calls this process an ‘Immediate Estimate’. With the help of the Immediate Estimate, the customer is informed of the scope and cost of the service as soon as they hand in their watch. The concessionaire can confirm the work to be carried out and the cost estimate directly onsite. If the customer agrees to the estimate, the concessionaire sends the watch to the service centre in Munich. It is immediately included in the ‘flow’ of the repair process.

The watches to be repaired are forwarded by the concessionaires to the Patek Philippe Service Centre in Munich, as concessionaires in Germany are only permitted to carry out minor work such as battery changes on quartz watches, strap adjustments or a water-resistance test. This is not the case for non-concessionaires. For example, only an authorised Patek Philippe service centre is given a special angle winder, which is responsible for winding the crown and thus setting the time. A non-authorised service centre might make it themselves. The watchmakers at Patek Philippe have already experienced some adventurous challenges. Every year, the Patek Philippe Service Centre in Munich receives several watches that are in an extremely poorly maintained condition.

Problems due to improper maintenance of Patek Philippe wristwatches

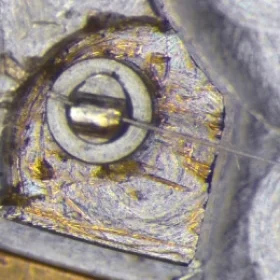

What can happen if a mechanical watch is not serviced for years?

If the interval service is not adhered to, this is often not immediately visible from the outside. This is because mechanical watches also have certain reserves. For example, a watch can continue to run for a while without the necessary lubricants, but then, even more parts have to be replaced later during servicing – similar to an engine failure in a car.

This can happen if a Patek Philippe is not serviced for too long!

The Patek Philippe workshop in Munich has also witnessed some major damage in its time. If watches are not serviced for many years, it can end up being much more expensive than taking your watch to the concessionaire on time. The damage can add up, depending on how many additional functions or complications a mechanical wristwatch has.

The service of a Patek Philippe

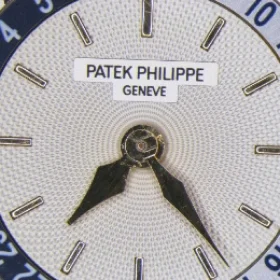

Using the example of the Nautilus 5811/1G-001

Nautilus Ref. 5811/1G-001

The maintenance procedure

Registering and archiving

When the watch arrives at Patek Philippe for servicing or repair, the process takes approximately six to ten weeks, depending on the model, age and complications. First, the watch is registered and the service history is traced using the international customer archive or, if necessary, a Patek Philippe historical archive.

Extensive photo documentation

To document the current condition of the watch, it is photographed and then sent to the workshop. There it is examined by a watchmaker and the scope of the maintenance or repair is determined. The watchmaker checks the accuracy of the entire watch and then removes the movement from the case. The case is then sent to the specialists for cases and bracelets. They inspect the aesthetic condition. Each owner decides for themselves what condition their case and the corresponding bracelet should be in when it is serviced.

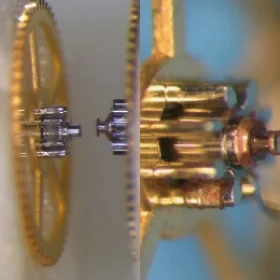

Systematic replacement of stressed parts

This careful inspection of all components is crucial for the proper performance of maintenance or repairs. Particularly stressed parts that are subject to heavy wear and tear are systematically replaced in the course of a service. All components of the movement are then cleaned.

Cleaning the movement

Servicing the movement

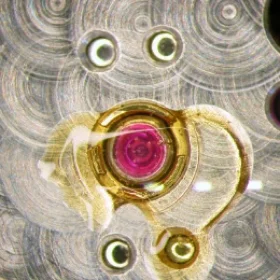

Once the cleaning process is complete, the watchmaker begins to assemble the watch. For a simple mechanical movement, this usually takes five to eight hours. Several hundred different work steps must be followed in order to put all the components back in their respective places in a precise sequence. Fine adjustments between the individual components ensure proper functioning. A mechanical movement generally has up to 150 lubrication points. These must be lubricated during reassembly. This is the only way to ensure proper functioning and resistance to wear. Applying the right amount of oil to the exact spot requires special dexterity. The wrong amount of oil can lead to increased wear and cause damage to the movement.

Checking the rate accuracy according to the criteria of the Patek Philippe Seal

The accuracy of the movement is tested in six different positions. These correspond to the usual positions of a watch and the strict criteria of the Patek Philippe seal. Finally, the watchmaker places the dial on the movement, checks the interaction of the moving parts and the distance between the dial and the hands. The hands are then attached and the watchmaker checks the functionality.

Polishing the case and bracelet

55 finishing steps by hand

The unmistakable design of the Nautilus by Gérald Genta is still characterised by alternating satin and polished finishes on the bezel, case and bracelet. Each watch requires 55 hand-finishing steps. Before polishing, the case is disassembled and washed. During the entire polishing process, the case is washed three to four times – depending on the goldsmithing, polishing and rhodium-plating work. The washing cycle is an essential part of the polishing process. It cleans the parts and, most importantly, removes all residues.

Case and bracelet polishing only at the express request of the customer

The case and metal bracelet are only polished at the express request of the owner. This is because marks and scratches are often part of the character of a watch and have emotional value for the wearer. Traditional polishing involves the use of abrasive discs coated with abrasive paste. Depending on the desired effect, the disc is made of fabric, felt, natural or synthetic hair. The shape of the disc is adapted to the particular work to be carried out.

Years of experience in polishing by hand

Polishing is manual work and requires more or less pressure depending on the material. The polishing process for the Nautilus in particular is extremely time-consuming. Years of experience are required to master the polishing technique. Sanding discs are used for satin finishing. They are covered with very fine-grained sandpaper. This process is mainly used when restoring casebacks.

Mounting the case

After polishing, the glass is glued into the case, depending on the model. It is then placed in a polymerisation chamber to solidify the adhesive. After carefully removing any excess adhesive, the housing is placed in the polymerisation chamber again to harden.

New seals are inserted. The caseback and crown are refitted. Water-resistant watches are tested for water resistance. Finally, a visual inspection is carried out before the case is returned to the watchmaker.

Encasing the movement

Final assembly takes place in a clean, dust-free environment. Before the movement is fitted, the inside of the case surface is cleaned. The watchmaker reinserts the crown and places it in the correct position. The addition of a small amount of silicone improves the functioning of the crown.

The watch is heated to remove any moisture inside

The last remaining particles are removed from the case, which is now partially closed. The watch is heated slightly to remove any moisture that may have accumulated. The caseback is then finally closed. After another accuracy check, the watch is taken to the final quality control station.

The quality control tests and confirms the work previously carried out on the Nautilus Ref. 5811 by each of the specialists. The final inspection process takes up to 14 working days. All functions are checked: automatic winding, power reserve, accuracy, water resistance and aesthetics. The automatic speed test checks the winding performance of an automatic movement within a specified period of time.

The criteria of the Patek Philippe Seal also apply to servicing. Upon successful completion of these tests, the most stringent in the Swiss watch industry after the Patek Philippe Seal, the watch is subjected to a final aesthetic inspection. The functions are checked one last time and the time is set. Once the bracelet has been fitted, the watch is vacuum-wrapped. Now it is ready to be returned.

Watchmaking training at Patek Philippe is extremely complex

The Patek Philippe service promise

‘We are convinced that in our family-run manufacture, the expertise required for the maintenance, repair and restoration of our watches is just as important as the expertise we need for the production of new watches. For this reason, we attach great importance to ensuring that this work is carried out exclusively by watchmakers who have been trained and certified by Patek Philippe.’