1960

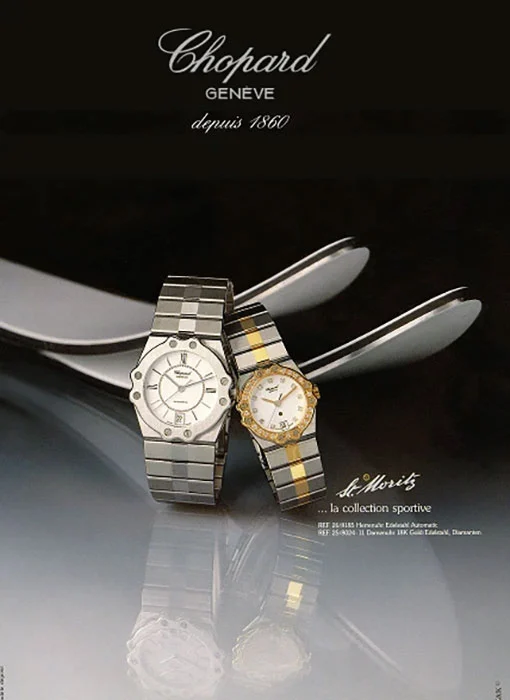

In the late 1960s, Chopard began creating ornate jewellery watches that blurred the line between timepiece and jewellery. These dazzling cocktail watches often featured dials framed by diamond-set bezels and integrated into sculptural bracelets of textured gold. During this era, the Maison launched a line of diamond-set models that would later inspire the contemporary L’Heure du Diamant collection. These pieces marked Chopard’s move into the world of diamond-set timepieces, setting the stage for the Maison’s creative explosion in the following decade.