The Servicing

of a Patek Philippe

Aquanaut Chronograph Ref. 5968A

What happens during the servicing of a high-end chronograph?

Why should a watch be serviced at all?

If you wait until a watch stops running or starts displaying a noticeably inaccurate time, damage to the movement has already occurred. This is because oils and greases, even modern synthetic lubricants, cannot stay in place indefinitely. Over time, they degrade or migrate, allowing mechanical wear to damage movement components.

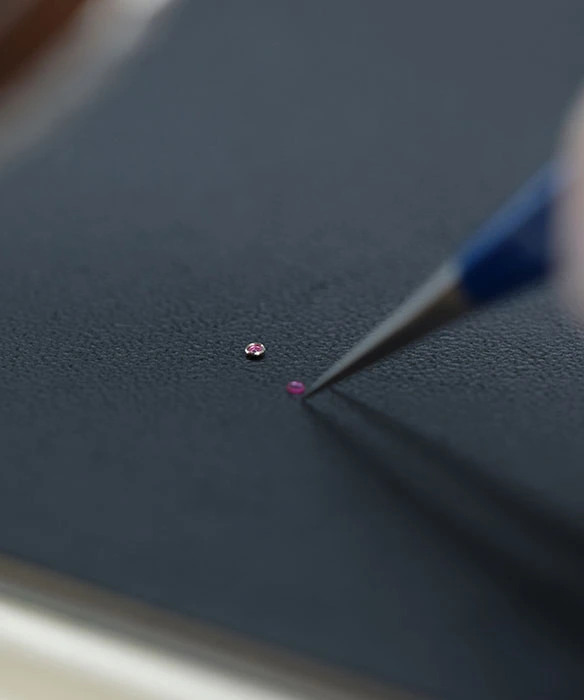

After a decade of operation, the ruby pallet stone of the Aquanaut chronograph will have arrested the escape wheel more than 1.26 billion times, a quiet endurance that ultimately calls for renewed lubrication.

The servicing of a Patek Philippe watch

Find out how servicing at Patek Philippe is usually handled and why high-quality timepieces should always be serviced by an authorised retailer.

Where can I have my Patek Philippe serviced?

Your authorised Patek Philippe retailer in Germany

Servicing a Patek Philippe Aquanaut Chronograph Ref. 5968A

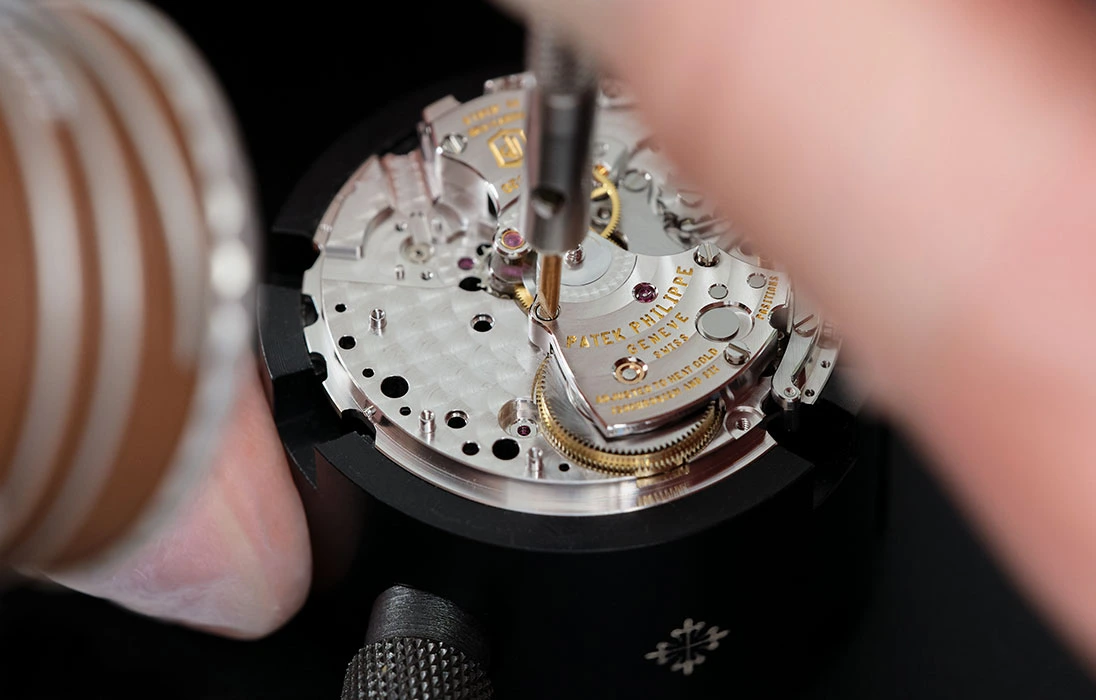

With a chronograph such as the Aquanaut Ref. 5968A, servicing involves a number of additional and particularly intricate procedures. We examined the key stages of this process first-hand at the Patek Philippe Service Centre in Munich.

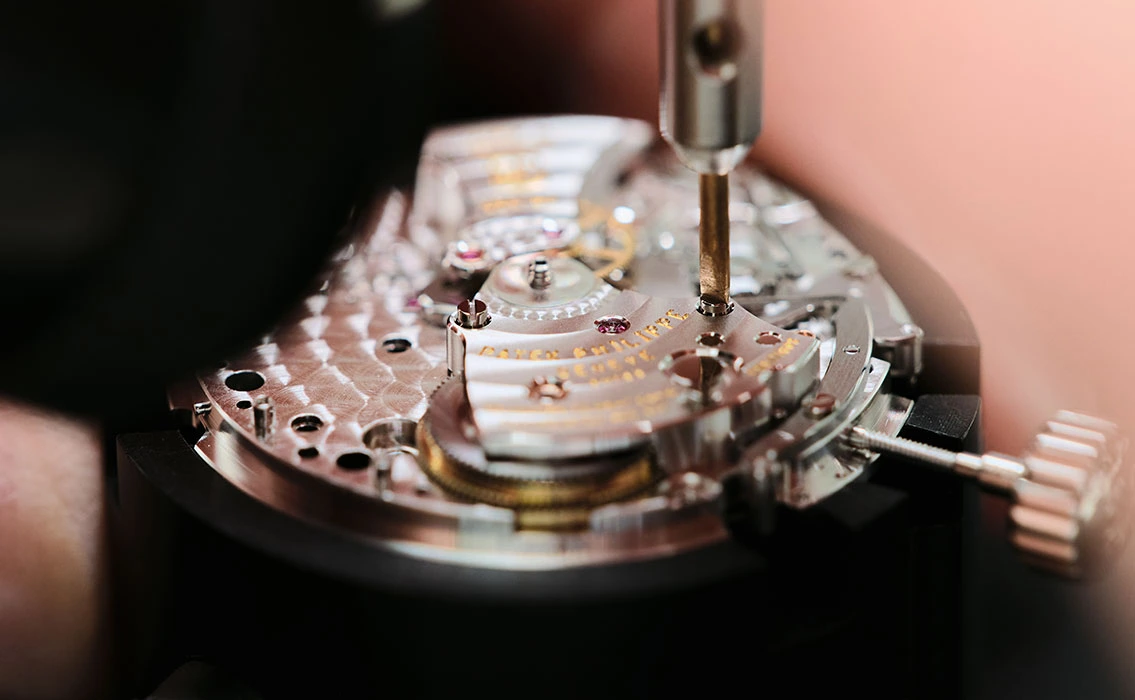

1. Removing the central chronograph seconds hand

High-performance equipment for the chronograph centre seconds hand

After removing the movement and dial from the case, the watchmaker uses a special tool to lift off the central chronograph seconds hand. The centre seconds hand cannot be lifted in the same way as the other hands, which are protected by a foil and removed with two hand levers, because doing so could otherwise damage the coupling beneath the chronograph centre wheel.

2. Disassembly of the movement

Stripped down to its individual components

The dial can now be removed, allowing the dismantling of the date mechanism beneath it. The watchmaker then takes apart all the movement components on the reverse side, step by step, including the automatic bridge, mainspring barrel, balance cock, balance, chronograph mechanism, wheel train, and motion works. Ultimately, only the mainplate with a few jewels remains.

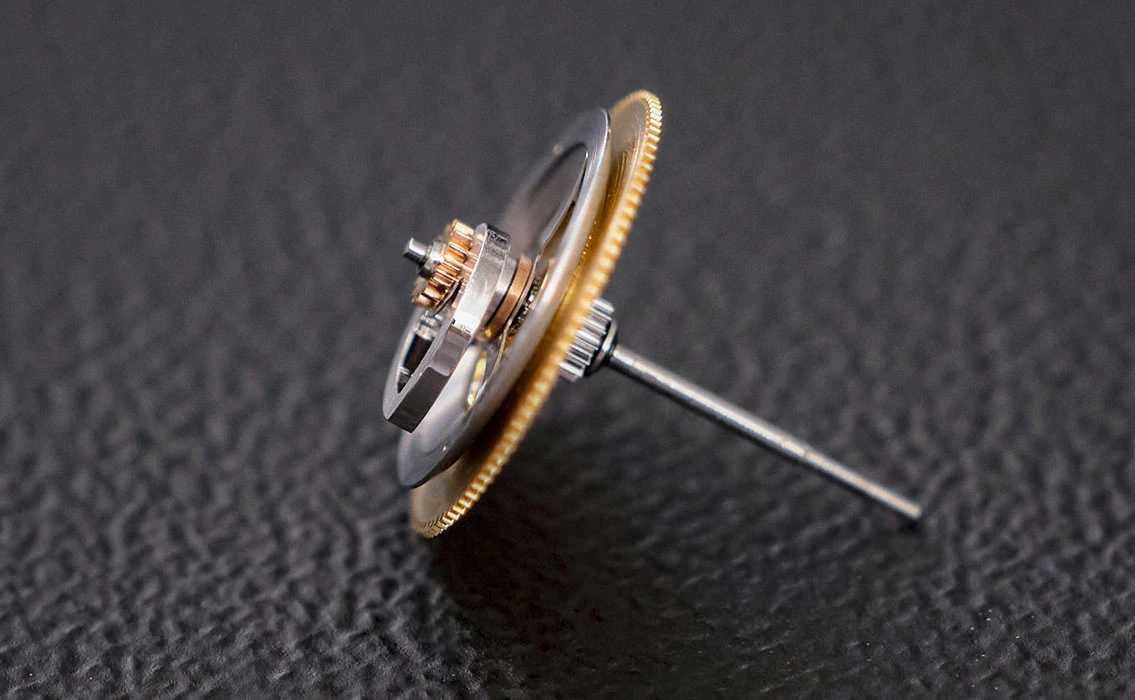

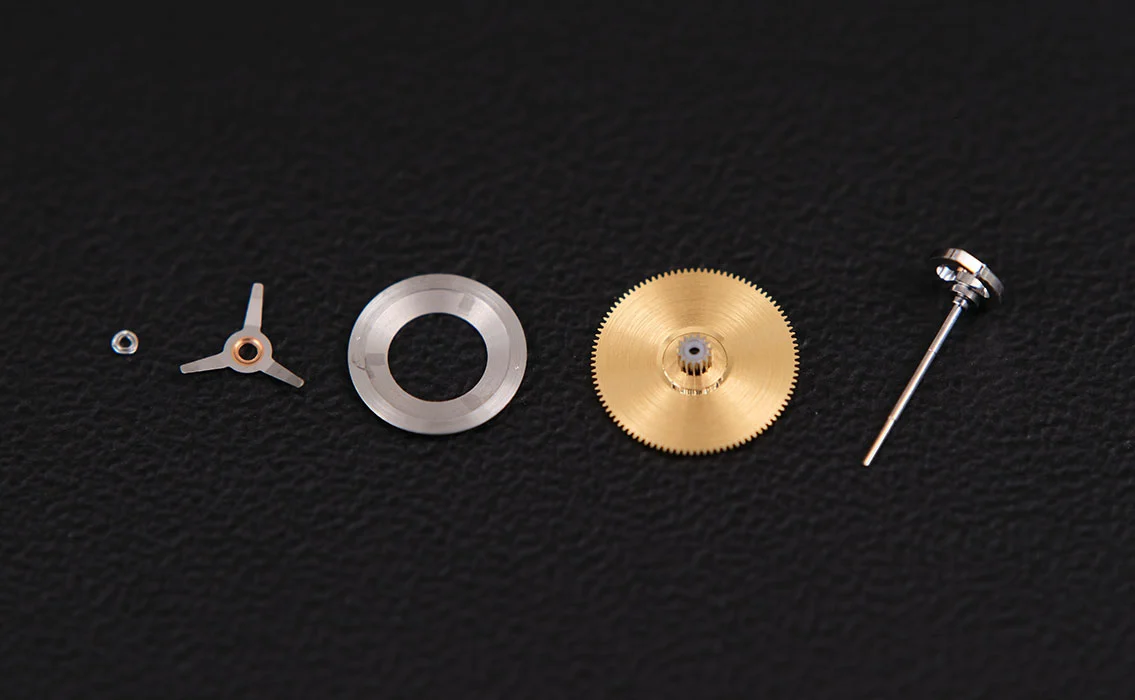

3. Removing the chronograph centre wheel

Chronograph centre wheel: coupling and reset

The chronograph centre wheel is at the heart of the CH 28-520 C chronograph calibre because it carries the multi-part vertical clutch that controls the rotation of the central chronograph seconds hand. Mounted on the same arbor is the heart cam, which works with the reset hammer to return the chronograph seconds hand to zero. The watchmaker removes and dismantles the chronograph centre wheel. As with all components, it is inspected for damage, with any debris being removed.

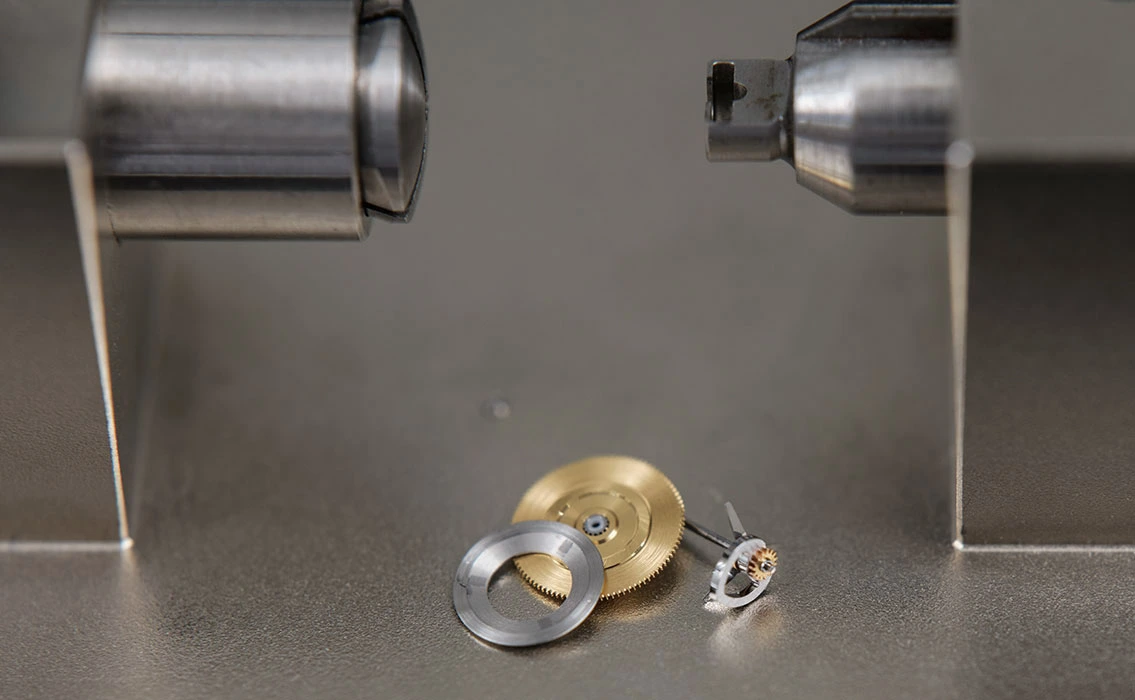

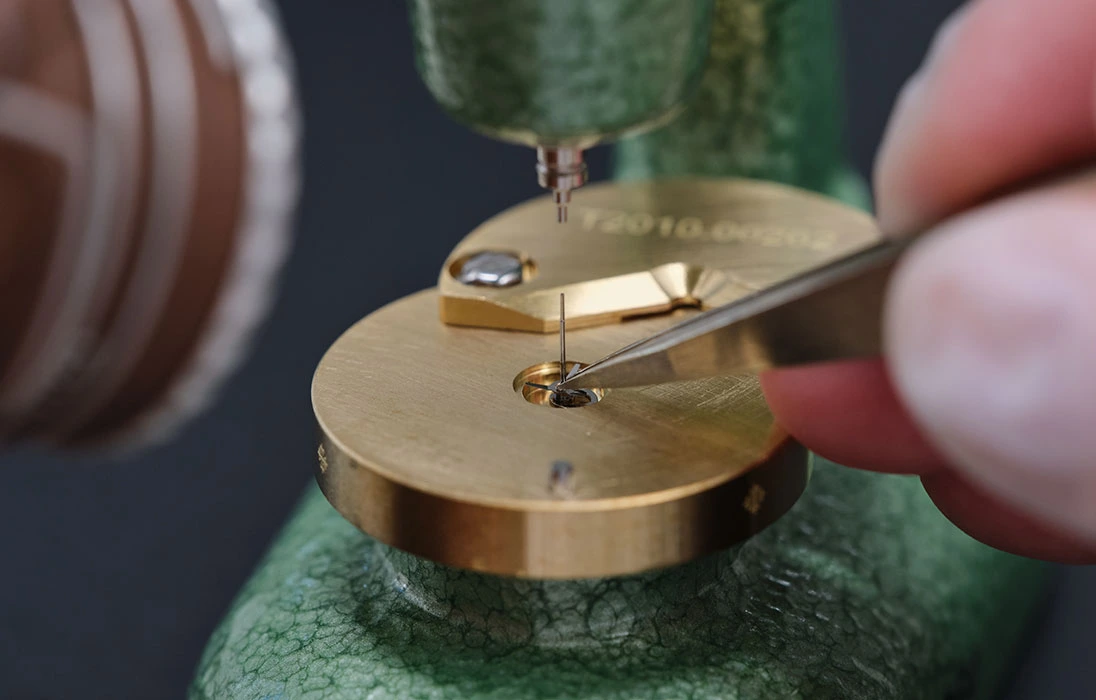

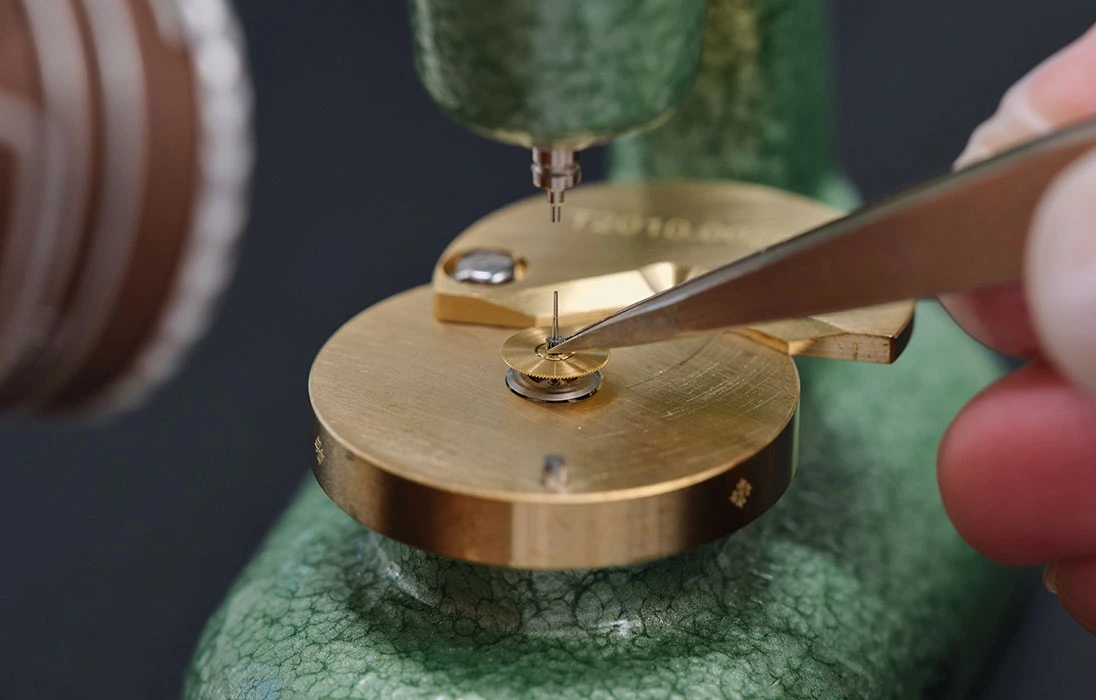

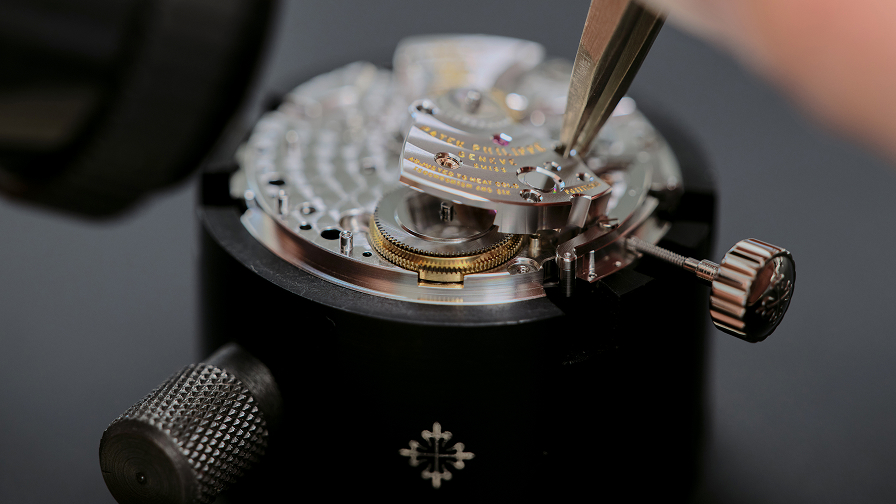

4. Reassembling the chronograph centre wheel

Assembling the heart with the clutch

Once all the movement parts have been returned from the ultrasonic cleaning machine, the chronograph centre wheel can be reassembled. Patek Philippe provides a special assembly tool for this purpose: a brass jig. It holds the shaft with the zero-reset heart and pinion, the three-armed spring, the connecting disc and the clutch wheel together until a bushing is pressed on. This bushing holds the system together at the correct distance, enabling the clutch pliers to open the clutch later via the sloping surface of the connecting disc. During assembly, each component is checked and any contaminants, such as dust particles, are removed using Rodico modelling clay. The functional surfaces are then lubricated using an oil dispenser.

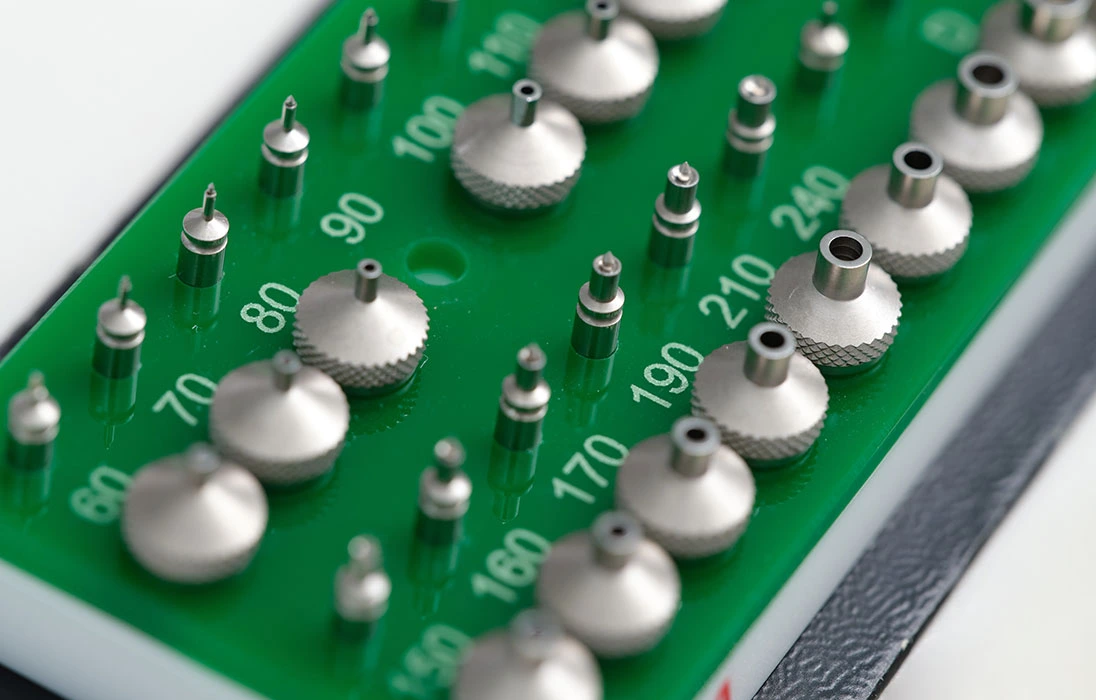

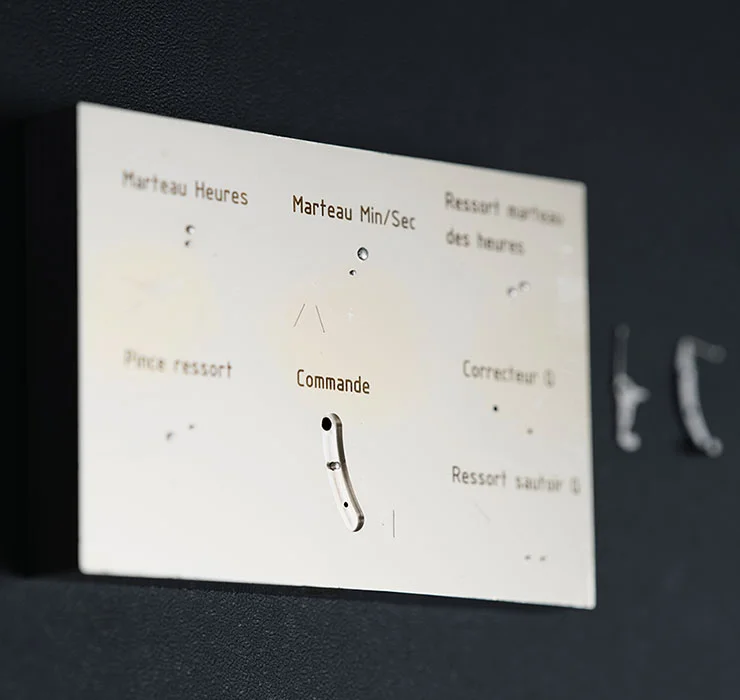

5. Aligning the chronograph levers with the spring gauge

Adjusting springs and levers

The watchmaker uses a spring gauge, a specialised metal tool, to check whether any of the chronograph springs are fatigued or bent. Any faulty springs are replaced, while others are carefully straightened with tweezers. Next, the chronograph mechanism, including the levers and coupling wheel, is reassembled in a time-consuming process due to the numerous lubrication points. The heights of the springs are also adjusted with great precision.

6. Assembling the movement

Everything comes together

Next, the gear train, mainspring barrel, bridges, and automatic winding mechanism are installed. The watchmaker assembles the escapement and balance wheel with its tiny shock absorber. The jewel bearings and ruby pallet stones are carefully lubricated in the process. Using a timing machine, the rate, beat symmetry, and positional variation are checked and adjusted, and the watch is regulated

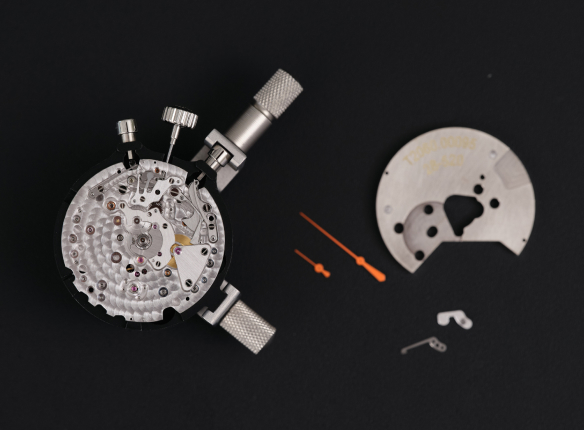

7. Checking the hand reset

Zero reset of the chronograph hands

To test the chronograph reset, the movement is placed in a special jig with pushers, onto which a test bridge is mounted. The central chronograph seconds hand and the chronograph minutes hand are then fitted, and the chronograph is started, stopped and slowly reset. The interaction between the reset hammer and the heart cams must function perfectly. The instantaneous date change is also checked.

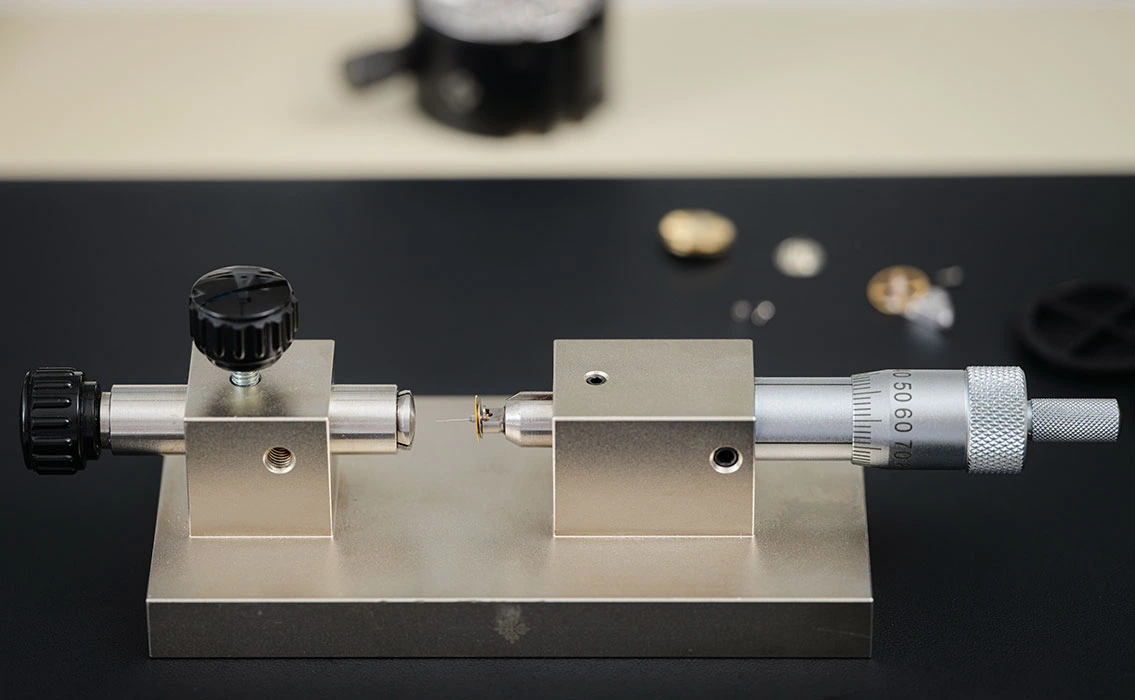

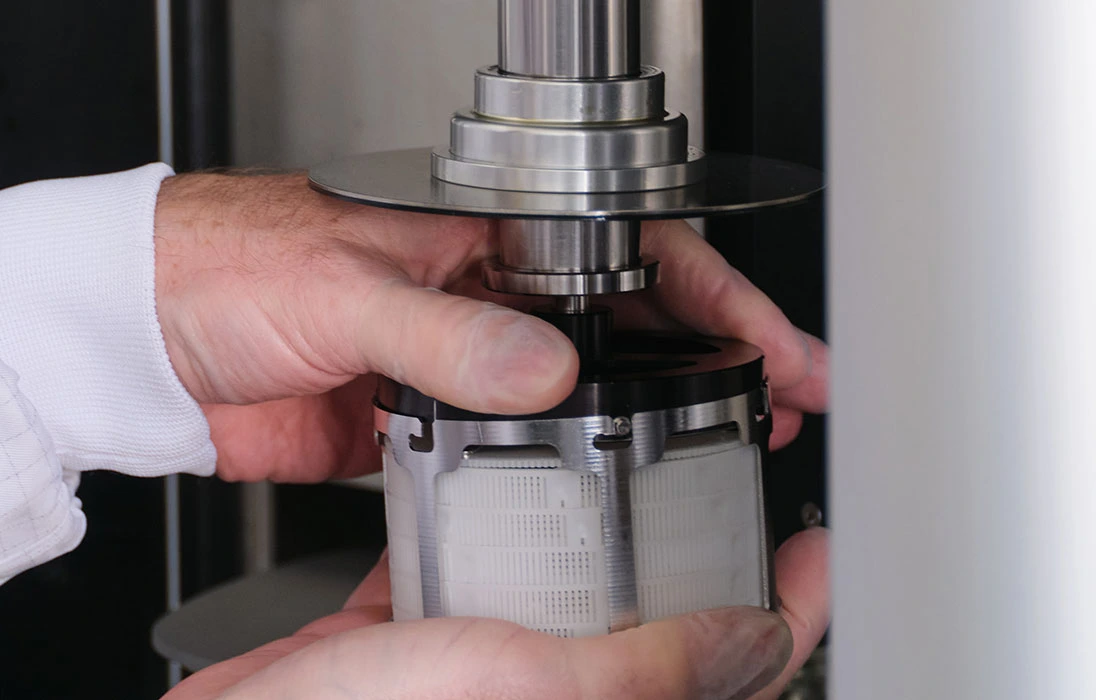

8. Setting the centre second hand

Mounting the Chronograph Seconds Hand

Once the movement has been regulated, the dial mounted, and the hour and minute hands correctly aligned for the date jump, the watchmaker can fit the chronograph hands. The central seconds hand requires special attention due to the significant forces acting on it during resetting, its length, and its slender arbor. If it were fitted in the same way as the other hands, it could eventually come loose during operation. To prevent this, the steel hand is pressed into place using a Forcetest device with a predefined force. For this reason, it must be replaced at every service, and the hand lining is carefully opened with a tiny awl so that the hand can be seated about one third onto the arbor before being firmly pressed into position.

9. Quality control

Function and precision test

Once the overhauled movement has been re-cased in the refinished case, it enters the quality-control phase, which alone takes nine days. During this period, the winding efficiency of the automatic movement is tested on a watch winder, the specified power reserve is verified, and rate accuracy is checked in different positions as well as after 0 and 24 hours. To meet the stringent requirements of the Patek Philippe Seal, daily rate deviation must fall within –1 to +2 seconds per day.

In total, a watchmaker spends around ten hours servicing the Aquanaut Chronograph movement itself. Additional time is required to restore the case and clasp, as well as to carry out several days of tests on winding, power reserve, and accuracy. Once water resistance and aesthetic excellence have been confirmed, the Patek Philippe can be returned to its owner. For them, it is a delightful moment: the movement is effectively as good as new – meticulously cleaned, perfectly lubricated and adjusted, and precisely regulated.

How often should the watch be serviced?

Patek Philippe recommends servicing its watches every eight to ten years. This helps ensure lasting rate accuracy and keeps the movement sufficiently lubricated to prevent excessive wear.

How long does servicing take?

Clients should expect a processing time of ten weeks for automatic chronographs before they receive their watches back. Quality control alone accounts for nine days of this process.

What qualifications does a watchmaker need to service the Aquanaut Chronograph?

After completing a three-year apprenticeship as a watchmaker, new Patek Philippe employees attend a five-week course in Geneva, qualifying them to service three-hand watches. Only after gaining at least three years of professional experience can they undertake a further six-week course in Geneva, which qualifies them to work on more complex timepieces, such as those with annual calendars and world timers. After a further three years, watchmakers can undertake a three-week specialist course covering Grand Complications like perpetual calendars and hand-wound or automatic chronographs. In total, it takes almost ten years and the successful completion of several training programmes before a watchmaker is authorised to work on chronographs.