Zenith presents its Defy Extreme Diver with a new silver-white dial.

Glashütte – the renowned town of German watchmaking – is home to Nomos, an innovator that has gained international acclaim for its minimalist design, aimed at achieving the maximum with minimal resources. During a visit to the manufacture, we had the opportunity to follow the entire process of creating a Nomos watch – from raw materials and the precise crafting of the smallest gears and plates, to the fine-tuning of a movement and its assembly into the case. This gave us a first-hand insight into a manufacture that seamlessly blends the time-honoured craft of watchmaking with cutting-edge technology. In this article, we invite you to join us on our journey through the Nomos manufacture.

Before we take a closer look at the manufacture, it’s worth exploring the history of the brand and its self-developed escapement, which helps us understand what has shaped Nomos into the brand we know today. On 1 October 2024, the Nomos management team – comprising the entrepreneurial trio of Uwe Ahrendt, Judith Borowski, and founding father Roland Schwertner – received the Order of Merit of the Federal Republic of Germany from the President in Berlin. This honour recognises the ‘German-German success story’ of Nomos, which stretches back to a time when the long-awaited desire for freedom led to the fall of the Berlin Wall on 9 November 1989, which had divided the Federal Republic of Germany (FRG) in the west and the German Democratic Republic (GDR) in the east.

The Nomos management team, consisting of Uwe Ahrendt, Judith Borowski and founding father Roland Schwertner, was awarded the Order of Merit of the Federal Republic of Germany on 1 October 2024.

Amid a profound sense of new beginnings and feelings of unity that permeated the collective German consciousness, Nomos Glashütte was founded by photographer Roland Schwertner as the first company to be re-established in Glashütte after the fall of the Berlin Wall – more specifically, during the final days of the GDR on 1 January 1990. The company’s name references the Nomos Uhr-Gesellschaft Guido Müller & Co., which imported Swiss watches to Saxony from 1906 to 1910, subsequently selling them under the more prestigious (and profitable) label ‘Glashütte/Sachsen’. However, this practice was legally challenged by local watch manufacturer A. Lange & Söhne, resulting in the original Nomos company ceasing operations in 1910. Apart from sharing the name Nomos, the “Nomos Uhr-Gesellschaft” and the current company “Nomos Glashütte/SA” have little else in common.

After seven years of development, an investment of 11.4 million euros, and collaboration with the TU Dresden and the Fraunhofer Institute, Nomos celebrated the introduction of its own regulating system into mass production at Baselworld 2014: the Swing System, a feature that significantly contributed to Nomos’s success. Nomos managing director Uwe Ahrendt even described the Swing System as the brand’s ‘own moon landing’. With the launch of the Swing System, Nomos declared a step towards independence away from the Swiss Swatch Group, the then-monopolist, enabling the company to determine and control the quality and production volumes of its movements. This system would prove to be the axis around which the brand’s future would revolve.

Although Nomos had only been producing in-house movements since 2005, the Swing System also laid the groundwork for proprietary calibres that were slimmer and more refined than anything previously seen from the brand. The ‘Deutschen Uhrenwerke’ (DUW), or ‘German watch movements’ in English, began with the Metro Datum Gangreserve (or in English, ‘Metro Date Power Reserve’) model, which was equipped with the DUW 4401, in 2014.

The Metro Datum Gangreserve was the first Nomos watch to be equipped with the new Swing system in 2014

Nomos Glashütte takes particular pride in the fact that the components of a movement and the associated production processes boast an in-house manufacturing rate of approximately 95 percent. ‘Doing it ourselves’ at Nomos Glashütte means covering virtually every aspect of production, from initial design to the final product, as part of its core competencies. The spectrum ranges from individual manufacturing and fine regulation to case assembly, all carried out in the three different manufacture buildings with over 180 employees in Glashütte. The first building, located by the railway station in Glashütte, previously housed the individual manufacturing. This now takes place at the production facility in Schlottwitz (a district of Glashütte), which opened in 2017. The third building, the Chronometry, was formerly the production site for Lange marine chronometers before being repurposed into a residential building during the GDR era, eventually being acquired by Nomos in 2000. Perched on a hillside, the building offers not only an excellent view of the town but also complete tranquillity.

The Nomos main building, the former entrance building to Glashütte railway station, now houses the administrative offices

Now, let’s turn to what Nomos sources from external suppliers. Two hours and ten minutes north of Glashütte, another 20 employees from the Nomos creative department, Berlinerblau, work daily, including graphic designers, authors, photographers, and product designers. Every day, about a dozen designers are tasked with giving the watches and their components minimalist characteristics. Once the drawings and specifications are completed and sent to partners, everything outside of the movement – meaning the case, hands, dial, strap, and clasp – is sourced externally.

The in-house creative department Berlinerblau is located in an old industrial loft that was once used for button production

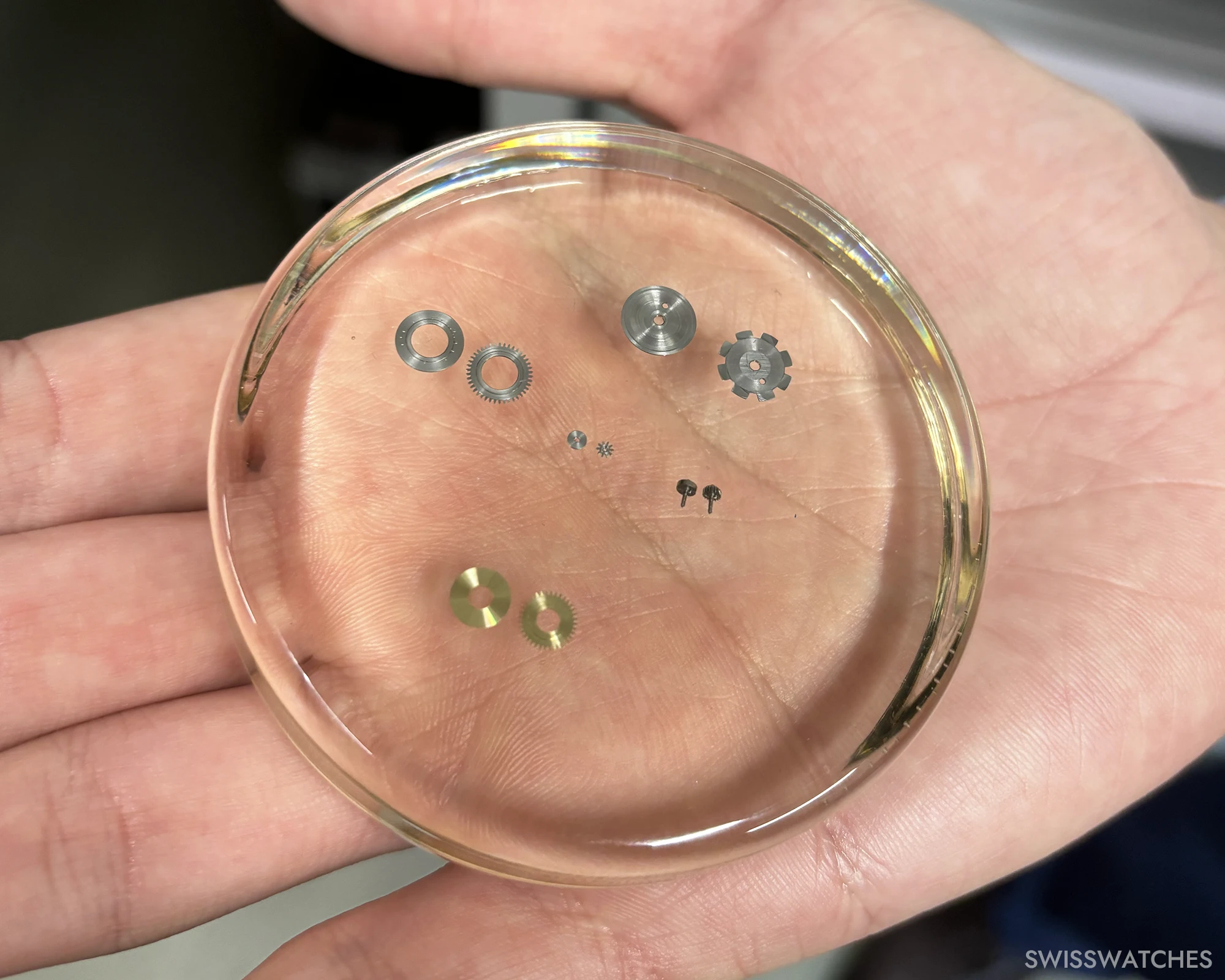

We begin our tour of the manufacture in Schlottwitz at Nomos’s production facility. In the various stages, which include turning, milling, gear cutting, fine machining, and finally finishing, a CNC long-turning lathe starts transforming three-metre-high steel and brass bars into turned components such as wheels, pinions, and shafts.

Nomos’s production facility in Schlottwitz

Once the individual parts are cut, employees meticulously ensure that they are precisely tailored to the movement. However, the introduction of the Swing System also brought significant changes to the individual manufacturing process. For example, the tooth profile of the movement wheels was optimised as part of the foundational research for the Swing System, resulting in a power transfer of 94.60 percent for the DUW 3001 movement, which has a height of just 3.2 mm. Prior to the establishment of the Swing System, a typical power transfer was between 80 to 85 percent.

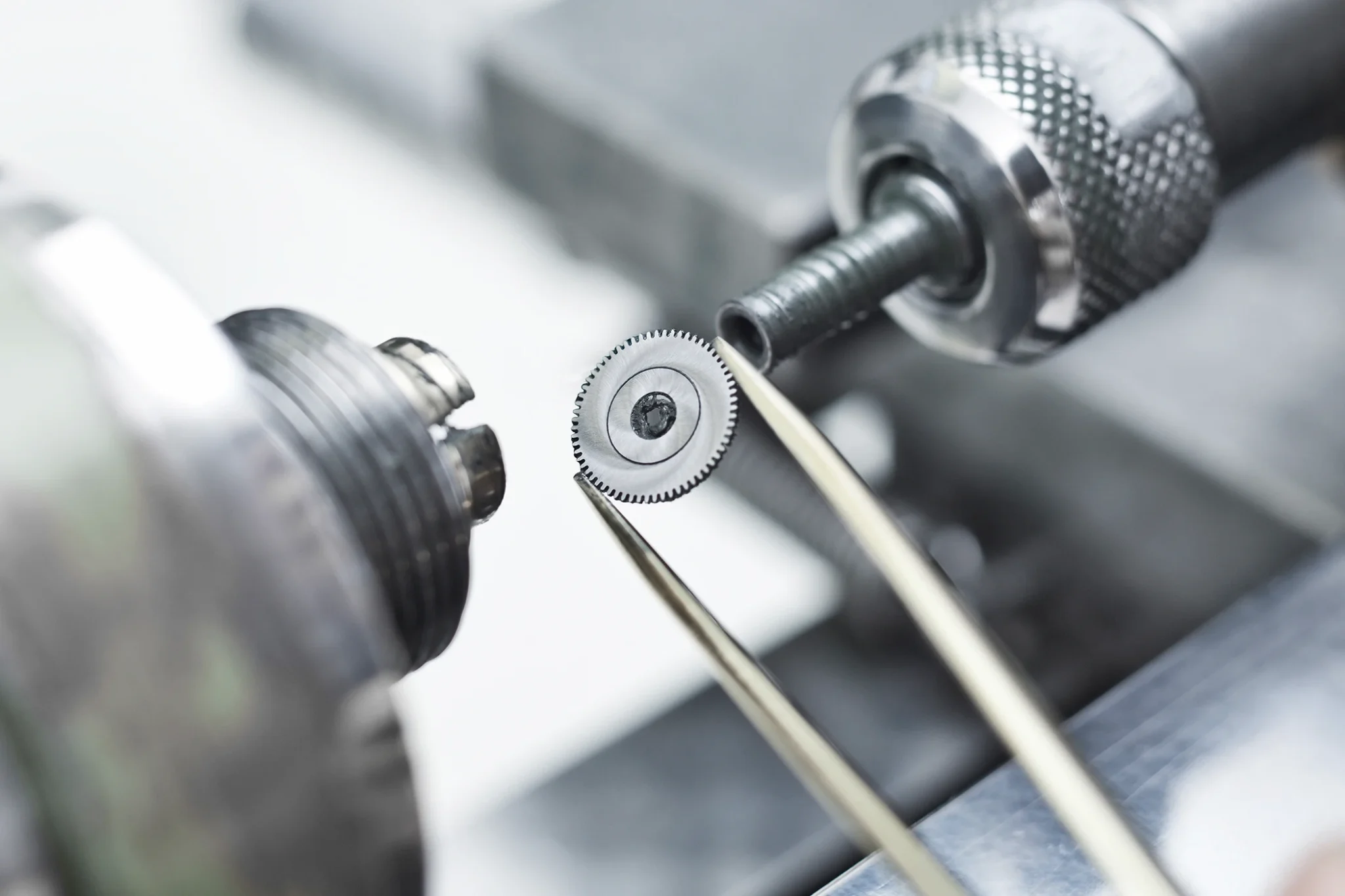

To manufacture a gear that is not available ‘off the shelf’, an employee carefully cuts each individual tooth into the tiny component, which measures only a few millimetres. Depending on the movement, the employee tells me, she produces between 400 and 500 gears each day. For comparison, a single DUW 6101 Neomatik Datum calibre – with ‘Neomatik’ referring to the completely newly developed automatic movements from the manufacture – contains 20 wheels and 28 pinions.

Next, we move to where plates and bridges, as well as steel springs, are milled, drilled, and shaped. This work is carried out using milling machines, including the largest, the ‘Lehmann’ milling machine, which can work on a variety of tasks continuously for three days without a break, utilising the jobs prepared in a special storage container in advance. The machine detects the marked tasks and autonomously prepares the programme it needs to execute. Known as the ‘Employee of the Month – every month’ in the individual manufacturing facility, the machine demonstrates how modern technology has profoundly shaped watchmaking today. Nonetheless, each new Nomos watch requires individual tool adjustments and the precise redefinition of programmes. This process can take up to one and a half years from the first prototype to the final production-ready watch, despite all technological advancements.

Only then is the Glashütte sunburst finish, developed by Ferdinand Adolph Lange, applied. At Nomos Glashütte, the sunburst finish can be seen on the large ratchet wheel and crown wheel. Meanwhile, striped finishing is applied to the balance cock, bridges, and the three-quarter plate.

After a short drive, during which we pass the only brick-and-mortar sales point of Nomos in the world – which Ferdinand Adolph Lange used as a workshop back in 1845 – we arrive at the third and final manufacture building of the Nomos Glashütte brand: the Chronometry. Nomos moved into this building in 2000, which had already been used as a production facility for Lange marine chronometers in the 1920s. In 2014, the year of the Swing System’s introduction, it was expanded with an additional annex that doubled its capacity.

The world’s only Nomos sales house served as Ferdinand Adolph Lange’s workshop in 1845

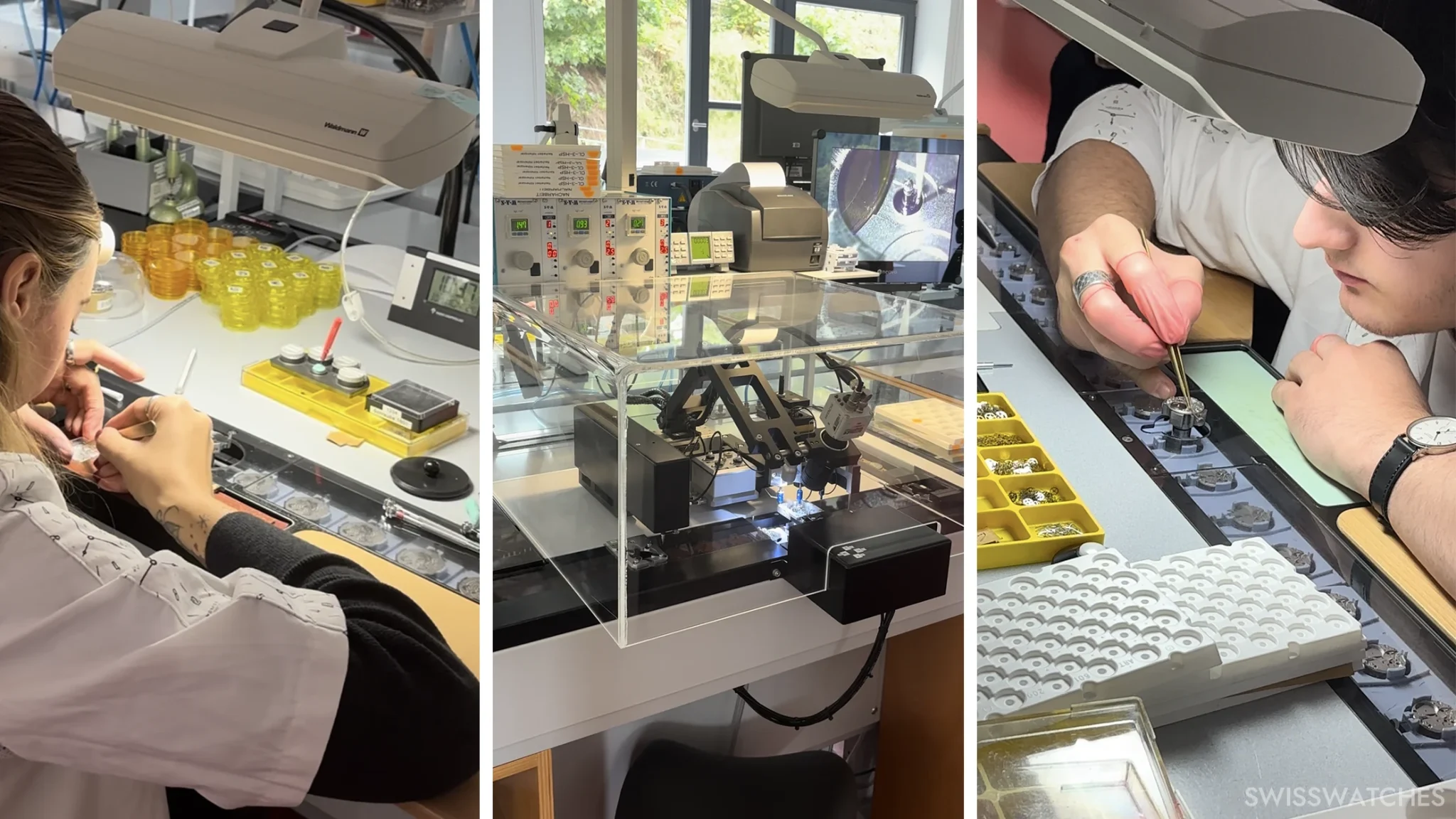

Here, there is a particularly strong understanding of how to harmonise innovation, which plays a significant role in the brand’s modern design philosophy, with the time-honoured craftsmanship of the German watchmaking industry. The experience of what it means when over 176 years of watchmaking art meets modern technology becomes a sensory journey at the Chronometry, the manufacture building of Nomos Glashütte. Across four floors, the parts that have been milled, gear-cut, and polished at the Schlottwitz production facility are assembled into finished watches, combined with the externally sourced cases, dials, and hands.

The Chronometry: a large part of the watchmakers work here, high above Glashütte

At first glance, not much has changed in the manufacture of a mechanical watch in the Nomos Chronometry over the past 200 years: watchmakers sit in white coats at their wooden workbenches, and the absolute silence is occasionally interrupted by the ticking of a movement or the clinking of a tool. However, a second look reveals that the watchmakers in the assembly area, alongside those in pre-assembly and regulation, are supported by robots that work alongside them at specially designed watchmaker’s tables. At each of these specialised watchmaker’s tables from the Swiss manufacturer Lecureux, up to 50 movements are stored in a dust-protected manner, before being transported to the watchmakers via a conveyor belt integrated into the table. The watchmakers then assemble the components from pre-assembly with various individual parts and finally screw them together. Additionally, the robots assist the watchmakers in inserting the various jewels into the movement and oiling them.

At each of these specialised watchmaker’s tables from the Swiss manufacturer Lecureux, up to 50 movements are stored in a dust-protected manner, before being transported to the watchmakers via a conveyor belt integrated into the table. The watchmakers then assemble the components from pre-assembly with various individual parts and finally screw them together. Additionally, the robots assist the watchmakers in inserting the various jewels into the movement and oiling them.

On this floor resides the pinnacle of the manufacture: the assortment (Swing System), which is the kit consisting of the balance spring, escape wheel, and anchor that ensures the watch’s accuracy. Here, it is assembled and calibrated, allowing the watch to begin ticking for the first time. This step, due to its technical complexity occurring at the micrometre level, is reserved for only a few watchmakers. According to Nomos, this is because the technical knowledge about the escapement is not readily available and can only be taught within the manufacture itself.

To bring the Nomos watch to life for the first time, the escapement is installed, and height adjustments are made so that the insertion of the balance results in power transfer, causing the watch to start ticking. When I ask one of the watchmakers responsible for this process what makes the first alliance between the Swing System and the movement special, he passionately replies, “It’s always a wonderful moment, as the work from the previous departments and our production comes together. As soon as the watch begins to tick for the first time, I know that everything has gone perfectly up to this point, and will continue to progress successfully through the watch.”

Finally, the movement is allowed to run in for four to five days without the case, enabling the oils within the movement to distribute and the components to harmonise with one another. This process culminates in the regulation, during which tiny amounts of material are removed from the balance rim using a small drill to balance the spring and the balance wheel, achieving an accuracy that approaches the standards of watches that undergo chronometer testing. After this, the watch receives its dial and hands in the final assembly stage, located in the attic. It is then fitted into its case. However, before the watch is completed, it undergoes one final accuracy test on the so-called watch winder, which simulates various everyday stresses. For about a week, it must demonstrate its performance in six different positions before the finished Nomos watch can leave the manufacture.