The Richard Mille RM030 Blue Ceramic EMEA Limited Edition is equipped with the new RMAR1 caliber and a declutchable rotor.

The masterminds behind OMEGA strive to be ahead everyone else. A milestone and watch for which the brand is probably most remembered by is the OMEGA Speedmaster Professional Moonwatch, which was the first watch they shot to the moon in 1969. That is nearly 50 years ago. In 2015, OMEGA introduced the world’s first Master Chronometer, a watch that is tested to its very limits by the renowned Swiss METAS (The Swiss Federal Institute of Metrology). A good reason for Swisswatches blog to travel to OMEGAs headquarter in Biel and find out everything about Master Chronometers.

METAS – the Swiss Federal Institute of Metrology

Until then, the renowned COSC certification that most watches possess has been a standard level of high quality achievement for watches. The classification Chronometer (the term used for COSC certified watches) is only reserved for watches with a very high accuracy. OMEGA and Swiss METAS have established a new 8-step test program, which now reaches a new level of classification and is only used by OMEGA so far. However, it can be taken advantage of by any watch brand. METAS is responsible for nearly all certifications in Switzerland – comparable to the German TÜV. Until 2015, they have never allocated certifications for wristwatches.

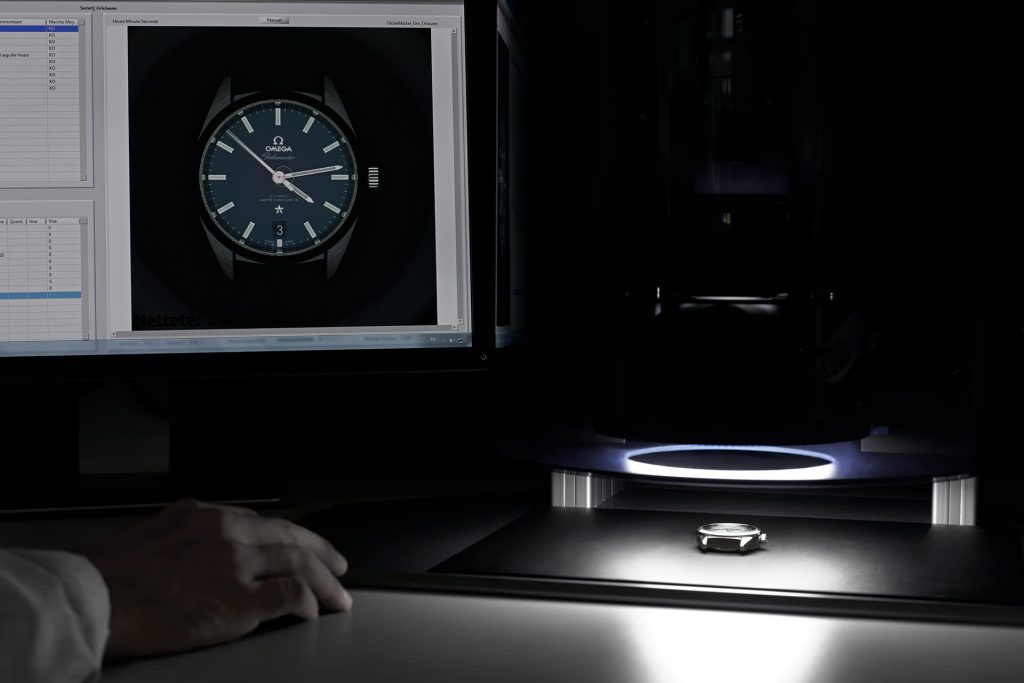

Hightech inside the laboratory

Members of staff from METAS come twice a week to the Institute’s own office at OMEGA and randomly pick calibres for examination. OMEGA takes this so serious that they allocated METAS a dedicated workspace at the fabric in Biel, which of course is strictly out of order for OMEGA members of staff. This leads to an authentic and transparent process for OMEGA and its customers in terms of quality. Each watch is now subjected to eight separate examinations, with every step carefully checking for function and accuracy.

METAS and OMEGAS 8-step examination

Part of this is – besides testing the average daily precision of the watch – its functionality during and after exposure to 15.000 Gauss magnetic field. That causes an enormous stress for the sensitive watch calibre and has an immediate impact on its accuracy. OMEGA is one of the few watch brands to be able to withstand such high magnetic exposure.

Exposure at 15.000 Gauss

First of all the calibre is tested on its own– in a second step the calibre inside the case. This is important because the calibre reacts differently when sitting in the watchcase. In today’s world, magnetic fields are all around (tablets, phones, even hairdryers) and therefore most watches are magnetic resistant up to a certain level. By the way, METAS only starts certificating watches resistant from 15.000 Gauss and more! OMEGAs goal and METAS requirements are to have a deviation of a maximum of plus 4 seconds per day. This is a remarkable achievement as most COSC certified watches have a deviation from minus 4 to plus 6 seconds per day. At OMEGA, minus is not an option any more because a few seconds ahead makes us just over-punctual rather then delayed. Swiss efficiency at its best.

The calibers are tested inside and outside the case

Another important part of the test phase is the water resistance of a watch. Even after METAS certification, OMEGA watches still are around 30 % more resistant than classified. Let’s say it is marked at 500 meters, it is approximately 650 meters resistant in real time, It now takes 25 days for all steps of tests until the watch will be classified a Master Chronometer. With COSC certification it only takes up to 10 days. OMEGA has pioneered this technology and is able to classify up to 200 watches as Master Chronometer per day. Their goal is to have this classification on all OMEGA watches by 2019.

Realtime conditions

Every owner of a Master Chronometer will receive a certification card. With its identification number they can track all test results of their personal watch online! The model OMEGA has chosen for this is the Globemaster which has first been introduced in the 1950s.

The Master Chronometer certificate