Unique in Every Way: The Father And Son Behind Horology Ancienne on Two Exceptional Minute Repeaters

Exclusively for Swisswatches Magazine, Horology Ancienne tells the story behind the 5240 and 4940 references from Patek Philippe.

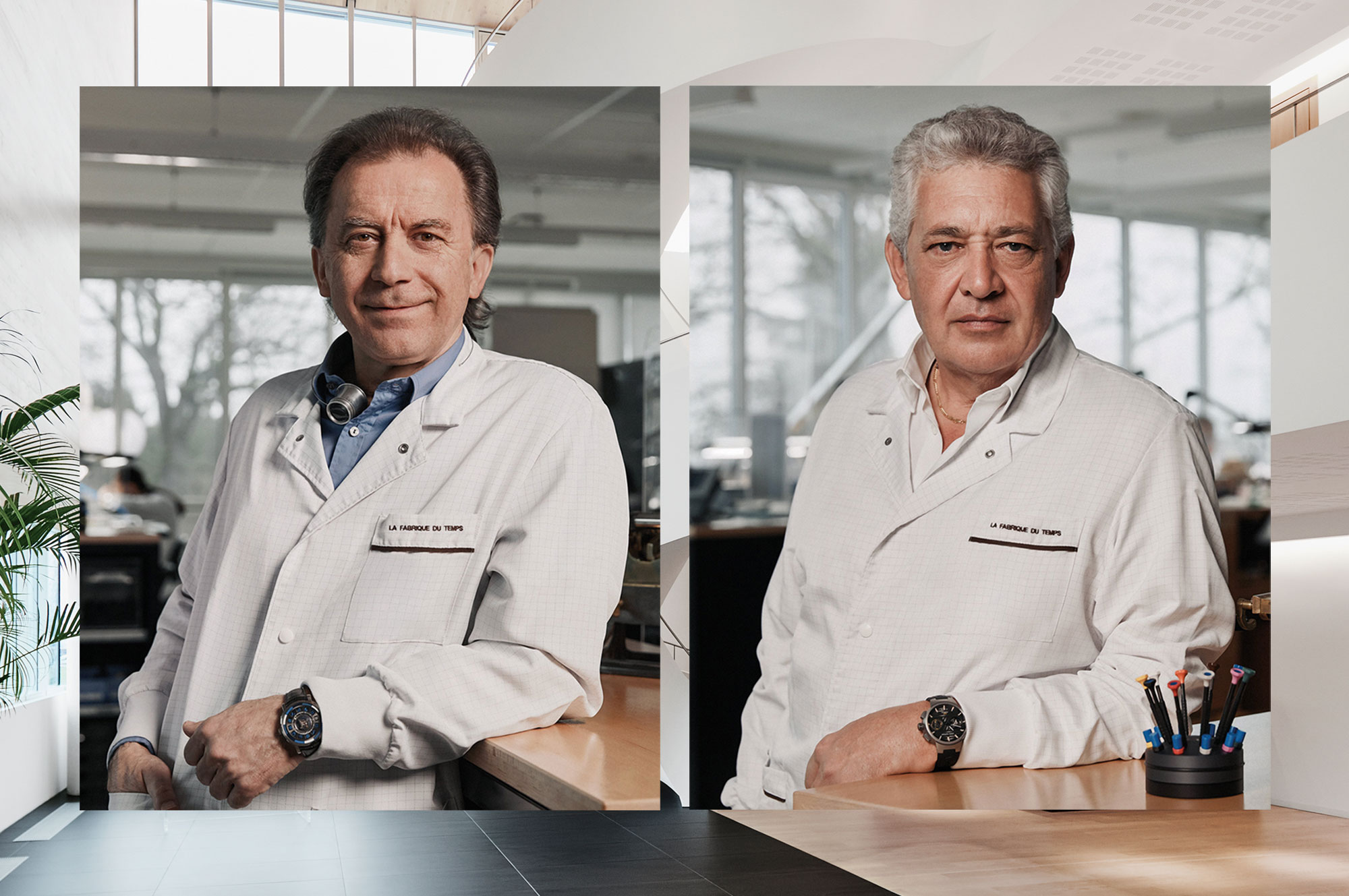

Were it not for a coincidence, Enrico Barbasini would probably be making it big as a musician, like his father, and not in the limelight as one of the most talented watchmakers of our time. Fortunately, a chance encounter gifted us Enrico Barbasini when his father (he was opera singer) met a young man with an angelic voice during a tour in Zurich in the 1970s. Although he was a trained watchmaker, he managed to weather his way through the quartz crisis through singing. It was this that ultimately led to Barbasini also becoming a watchmaker and later getting a job with Gérald Genta, where he also met his companion Michel Navas, an equally talented watchmaker with whom Barbasini now runs La Fabrique du Temps Louis Vuitton, where the pair create exceptional timepieces. But what motivated the two master watchmakers, with their passion for grand complications, to work for a luxury maison like Louis Vuitton, which for most of its existence had nothing to do with mechanical watches?

Unlike Enrico Barbasini, Michel Navas was practically born into watchmaking. As his father was a watchmaker, he came into contact with mechanical watches at an early age. His brother also works as a watchmaker today. After studying at the Horology School in Besançon, Navas gained experience at Audemars Piguet, Patek Philippe, Frank Muller and Gérald Genta in the 1990s, where he eventually met Enrico. The two watchmakers developed a particular passion for highly complex mechanisms. At AP and Patek, Barbasini and Navas worked on the watch manufactures’ high complications. Even then, it was clear that there was a very special chemistry between the two personalities, which made them an inseparable duo and led to the founding of a joint company in 2004. Together with fellow watchmaker Mathias Buttet, who had previously worked as technical director at Franck Muller, Navas and Barbasini founded BNB Concept, which was made up of the first letters of their surnames. There they produced high complication movements for watch brands. Even Rexhep Rexhepi (Akrivia) worked as a watchmaker at BNB Concept for around two years.

However, due to differences of opinion, Navas and Barbasini left BNB Concept in 2007 and founded La Fabrique du Temps – but this time without a third party. Mathias Buttet continued to run BNB Concept until 2010, when the company ran into financial difficulties and was acquired by Hublot, along with its last remaining founder on board, Mathias Buttet, who is now R&D Director at Hublot.

Laurent Ferrier Caliber LF 619.01 – developed in cooperation with Navas and Barbasini

La Fabrique du Temps established itself as a prestigious watchmaking workshop, focusing on tourbillons and repeater watches for various watch brands – for up to 13 brands at its peak. They developed the legendary LF 619.01 tourbillon movement for their friend and independent watchmaker Laurent Ferrier, with whom they had previously worked together at Patek Philippe. In 2008, his son Christian Ferrier even joined La Fabrique du Temps as a watchmaker.

Then, something wholly unexpected happened. Hamdi Chatti, then-Vice President of Louis Vuitton Jewellery & Watches, approached Navas and Barbasini to see if they could envisage selling La Fabrique du Temps to the LVMH Group under their leadership. Chatti had previously worked at Piaget, Harry Winston and Montblanc, and had the necessary experience and interest in the watch segment.

Louis Vuitton started out in the mechanical watch business as an establishment in 2002, sourcing movements from ETA, Dubois-Dépraz, La Joux-Perret and Zenith. LV ran a watchmaking workshop in La Chaux-de-Fonds to assemble the watches, but the luxury maison had bigger plans and wanted to play in the haute horlogerie league in the long term. Of course, this was only possible with the necessary expertise, which the company recognised in the two master watchmakers and their workshop La Fabrique du Temps. Navas and Barbasini agreed, leading to LVMH acquiring their workshop in 2011. As Michel Navas says today, “Louis Vuitton was known at the time for its suitcases, fashion and leather accessories, but not for high watchmaking. It was a completely new field for them, and that appealed to us because we could fully realise our vision and creativity. When you work for a brand that has a long tradition, you are limited in a way because you have to respect their values. It was a challenge, but also a great opportunity for us.

What’s more, Navas and Barbasini were still looking for a suitable housing for their unusual Spin Time mechanism. The idea for the Spin Time, in which small rotating cubes display the time, came to Navas in 2009 when he was travelling at the airport and saw the departure board on which a rotating mechanism displayed the list of cities and departure times. Louis Vuitton’s unmistakable Tambour case was the perfect fit, as its drum-shaped form provided sufficient space for the voluminous mechanism.

In March 2012, LVMH acquired the two dial manufacturers ArteCad and Léman Cadran in order to further expand its own watchmaking expertise. In October 2014, Louis Vuitton then inaugurated a 4,000 square metre watch factory in Meyrin, a suburb of Geneva. The original site in La-Chaux-de-Fonds was closed or integrated into it. One of Navas and Barbasini’s conditions for taking over their La Fabrique du Temps was that the new factory building had to be located in the canton of Geneva, as they wanted to have their years of expertise in watchmaking graced with the Geneva seal, which, even today, only a handful of watchmakers possess due to its strict criteria.

In 2016, just five years after the takeover of LVMH, Navas and Barbasini presented the Voyager Flying Tourbillon, the first Louis Vuitton watch to be certified with the Geneva Seal. Their wealth of ideas seems to be inexhaustible, and the two watchmakers have certainly found their playground in Louis Vuitton. Their creations are certainly playful, from the Spin Time to the automatons such as the Tambour Opera, the Tambour Carpe Diem, or the Tambour Fiery Heart, whose dials delight those who see it with a wealth of animations at the touch of a button. The Tambour Spin Time and the automatons are among the greatest inventions that Navas and Barbasini created for Louis Vuitton at La Fabrique du Temps.

However, as Navas himself says, the Twin Time Chronograph is probably the most complicated watch in the portfolio. It was specially developed for the America’s Cup and is equipped with a unique chronograph mechanism that measures two different times (of two competing regatta boats) and displays the difference between these two measured times. The Tambour Street Dive and Tambour Carpe Diem have won prizes at the prestigious Grand Prix d’Horlogerie de Genève (GPHG). As if that wasn’t enough to keep the two watchmakers busy, Navas and Barbasini have also been responsible for the movements of the new Gérald Genta and Daniel Roth watches since last year – LVMH recently acquired the licence for the two brands. Even Dior, which belongs to the parent company LVMH, has its tourbillon movements manufactured at La Fabrique du Temps.

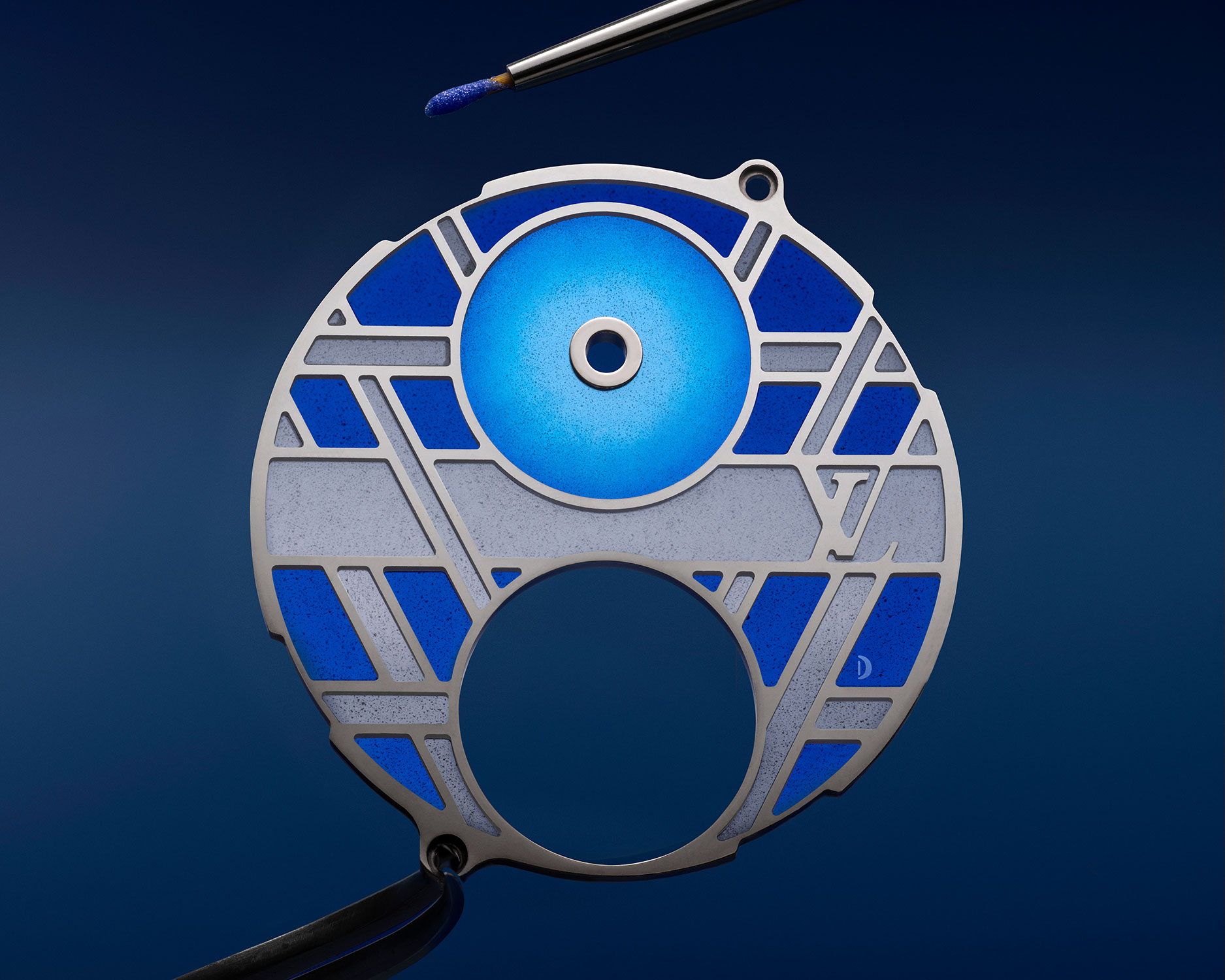

Even today, movements from external suppliers can still be found in Louis Vuitton watches. But the company is working steadfastly to produce an increasing amount in-house. Of the 30 or so watchmakers currently working at La Fabrique du Temps, only a handful have mastered the intricate movements bearing the Poinçon de Genève seal. In addition to watchmaking expertise, LV also relies on in-house métiers d’art. At La Fabrique du Temps, dials are not only produced, but also elaborately finished: engraving, enamelling, miniature painting and gem-setting are already fully integrated. The guilloché division is currently being further expanded, for which the manufacture is locating, purchasing, and restoring old guilloché machines in-house. Today, La Fabrique du Temps Louis Vuitton has around 200 employees. Louis Vuitton has just unveiled the new Voyager Flying Tourbillon Poinçon de Genève Plique-à-jour, whose dial is produced using a complex enamelling process that only a handful of craftsmen still master today. Approximately 100 hours of work go into one dial.

Despite all these milestones and the attention that Navas and Barbasini receive today, the two watchmakers have always remained down to earth, very authentic, and incredibly likeable. Anyone who has had the honour of meeting them in person knows this. When asked which complication is Michel Navas’ personal favourite, he replies: “A simple three-hand watch. I love simple watches. I can develop and build all kinds of complications, but the most difficult thing about watchmaking is creating simple things.”