Jaeger-LeCoultre is presenting several creative Reverso Metiers Rares innovations at Watches and Wonders 2025.

When it comes to measuring time, standing still is a bad idea. But it’s not just the watch itself that should never stand still in the best case scenario – or, in the case of a mechanical watch, provide perfect information again after manual winding or a quick shake of the wrist and setting the current time.

Engineers and designers alike have to keep moving to meet the expectations of watch enthusiasts and collectors.

Manufacture A. Lange & Söhne, from the Saxon watchmaking hotspot Glashütte, never disappoints the community in this respect and has several genuine innovations in its quiver for this year’s Watches & Wonders.

One of them is exemplary in its ability to combine tradition, technical expertise and the current preferences of watch wearers – or rather in a case. And this measures just 34 millimetres in diameter and 6.4 millimetres in height: an extremely popular format – and currently the smallest in the Glashütte manufacture’s portfolio.

Unsurprisingly, despite this limited space, A. Lange & Söhne has succeeded in integrating a top-class inner workings. This is in the form of the newly developed manufacture calibre L152.1, the 75th in the modern era of the traditional company with a moving past.

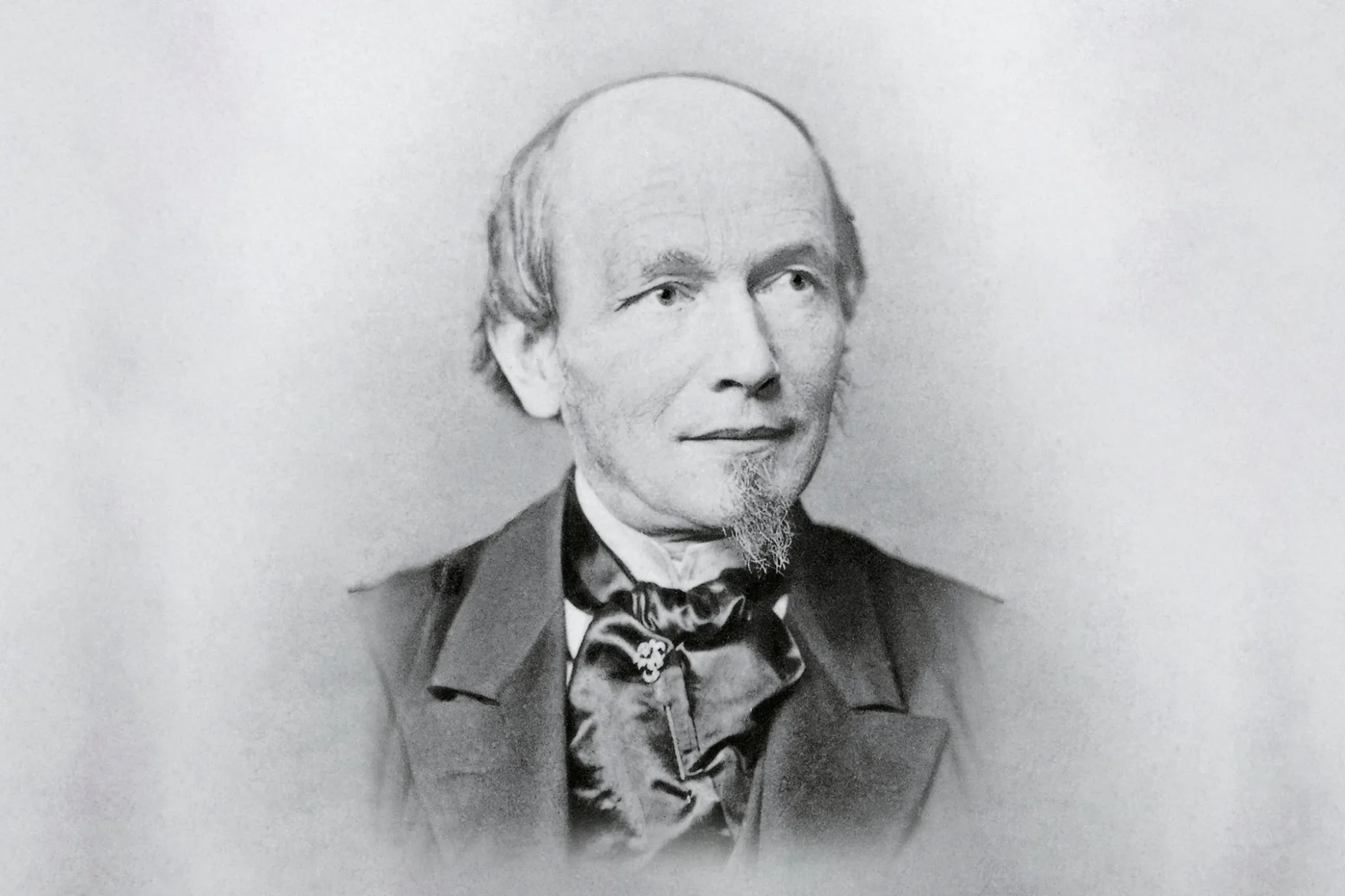

The first history of A. Lange & Söhne begins in 1845, when Ferdinand Adolph Lange, born in Dresden in 1815, founds the Lange & Cie. manufacture.

After completing his watchmaking training and two years as a journeyman, he initially gathered a great deal of knowledge while travelling through France and Switzerland. He recorded the resulting ideas in a sketchbook and travelling book.

This was the foundation stone for today’s luxury watch manufacture A. Lange & Söhne. When he returned to Dresden in 1845, he founded the Lange & Cie manufactory. He had received a repayable loan of 7,820 thalers from the Royal Saxon Ministry of the Interior for his idea of creating a new line of business for the completely impoverished inhabitants of the Ore Mountains.

He also encouraged qualified employees to set up their own companies. And he was extremely successful in doing so. Today, we would probably call it a successful start-up strategy.

Ferdinand Adolph Lange himself became mayor of the small town and, among other things, introduced the three-quarter plate – today a hallmark of watches from Glashütte. In 1868, his son Richard Lange became co-owner of his company, and after the founder’s death, his grandsons Richard and Emil took over.

In 1924, another member of the family was born, who would dedicate his life to watchmaking. Walter Lange, great-grandson of Ferdinand Adolph Lange, also worked in the family business after training as a master watchmaker.

On the last day of the Second World War, Lange’s production building was almost completely destroyed and the company was expropriated three years later. In the same year, Walter Lange fled to the West and the history of the manufacture was interrupted for many years.

Immediately after reunification, he was drawn back to Glashütte and founded Lange Uhren GmbH on 7 December 1990 together with the unforgotten watch manager Günter Blümlein.

The fact that they had foresight and great visions is demonstrated by the fact that they registered the A. Lange & Söhne brand worldwide at that time. The first watches were presented as early as 1994, including the Lange 1 with the L901.0 calibre, which remains the icon of the manufacture to this day and is characterised by its decentralised time display and large date.

Just how successful the venture of founding a new company was and how right Walter Lange and Günter Blümlein were with their vision was demonstrated, among other things, by the fact that construction of a new factory building began in 2012, which was occupied in 2015, two years before Walter Lange’s death. Today, around 5,500 watches are produced here every year on 4,500 square metres.

From the very beginning, the manufacture’s credo has been to break new ground – especially in the field of movement technology. And so, A. Lange & Söhne is now presenting its 75th calibre since the company was founded. The L152.1. is housed in either the 34-millimetre 750 red or white gold case of the new family member of the 1815 collection, which is named after the year of Ferdinand Adolph Lange’s birth.

Despite the limited proportions, no compromises were made in terms of design quality, attention to detail and technical sophistication. And so, like its larger relatives, this 1815 radiates superior elegance. The narrow, slightly stepped bezel forms the stylish frame for the silver dial in blue, equipped with railway minute markers, Arabic numerals and small seconds at 6 o’clock. It is reminiscent of the earlier pocket watches from A. Lange & Söhne. Together with the lancet-shaped hands in 750 gold, this fully reflects the classic orientation of the 1815 collection.

The manufacture combines these references to its own past with modern movement technology. The high precision of the new models is based on a new oscillation system with a free-sprung balance spring and large screw balance.

The oscillating system of a mechanical watch is the indispensable clock generator, without which there would be no accuracy on the dial. It consists of a balance wheel and escapement and ensures that the gear train runs at a precisely defined speed.

“The challenge with the new 1815 was to make the proportions of the timepiece even more elegant while maintaining its simplicity and functionality,” explains Anthony de Haas, Director of Product Development.

“And despite the smaller dimensions, our watchmakers also managed to increase the power reserve to 72 hours and integrate a new gear section.”

It doesn’t work without decoration. The Glashütte manufacture does not stop at technical excellence. The art of elaborate finishing is taken to the extreme in the truest sense of the word. To the pinnacle of skill, of course.

The smallest parts and even those that are no longer visible after assembly are skilfully decorated. And this was done back in the days when there were no glass shelves through which the decorated works could be admired.

Originally, decorations such as the perlage served to protect the moving parts of the movement, as the fine indentations and grooves could bind any dust in the case. Today, the cases are completely sealed and this effort would no longer be necessary. However, like many high-quality manufacturers, A. Lange & Söhne continues to uphold this beautiful tradition.

The finishing techniques used include band, sun, line, circle and circumferential grinding, perlage, flat and black polishing, bevelling, polishing of the inner corners and, of course, engraving.

It goes without saying that A. Lange & Söhne also reveals this part of the movement’s artistry in the new 171-part, five-layer finely regulated calibre L152.1, which has a diameter of just 28.1 millimetres.

In addition to the mechanical aesthetics, the hand-engraved balance cock, the three-quarter plate with Glashütte ribbing, gold chatons and blued screws can be seen through the sapphire crystal caseback. The price of the new Lange 1815 is 27,000 EUR.