We don’t know which fancy name drew more attention to us first: “Rexhep Rexhepi” or “AkriviA”.

A few weeks back we were kindly invited to discover the new Panerai manufacture headquarter which is idyllically located in the mountains just above a lake near Neuchâtel, the heart of the world of fine watchmaking. It’s equipped with incredible advanced technologies, a ‘think tank’ department called The Laboratorio di Idee, the RFID system to streamline processes more efficiently and at the same time, the manufacture produces no carbon dioxide emissions. What a great fancy story for a watch brand.

Think Tank Laboratorio Di Idee

By entering the building you can instantly see the Italian roots of the brand. Interior and design are very well selected and the building almost looks like a Milanese design studio. On the other hand it is equipped with high-tech like a space shuttle. Incomparable Italian design meets Swiss technological excellence.

Design meets function

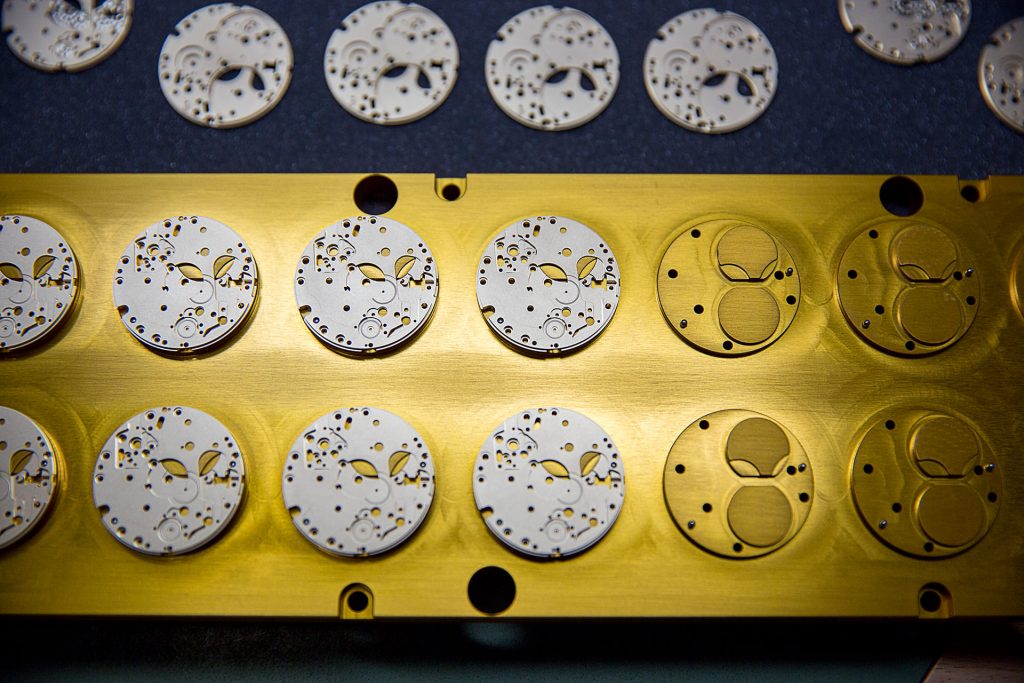

The building with 10.000 square meters was completed in 2014 and for the first time all skills and resources for the development and production of Panerai watches and movements are completely made in-house under the same roof. 250 employees take care for a smooth running process. Since 2005, Panerai first introduced in-house manufactured movements to the public and now, 12 years later has created a complete range of mechanical calibres – hand-wound and automatic. Panerai’s challenge is to be at the upfront of innovative technologies and at the same time preserve the roots of the brand, which originally created watches in the 1930s and 1940s for the commandos of the Italian Navy. The goal is to keep the look from past times and pair it with solid, reliable mechanical calibres of exemplary simplicity or fitted with the most sophisticated complications.

Inhouse movements since 2005

A remarkable and innovative aspect of the new manufacture is the use of the so called RFID (radio frequency identification). It’s a micro chip which is attached to all parts which run through the production procedure and can be determined at any time. By monitoring all steps it allows the individual teams to work more efficient. And there are over 70 divisions involved. This really seems the future of watchmaking in perfection.

Precision in perfection

Another part of the manufacture to preserve the history of the brand is The Laboratorio Di Idee. The Florentine family which founded the first watchmaking workshop in the Tuscan City in 1860, inspired Panerai to establish a research and development department called The Laboratorio di Idee. It is devoted to experimentation and implementing highly innovative ideas and designs as well as developing new products from the original idea. It consists of more then 50 experts who all work very closely with the design department. By the way, the design department is based in Italy at the brands historic archives. Another indication for Panerai’s importance to preserve the brands identity.

Panerai Manufacture

A final but not less important part of the new manufacture to mention is their care of environmental sustainability. The building is equipped with the most modern devices for energy saving and the recovery and reuse of waste materials. Rainwater is saved in a tank of 50.000 litres and then reused. Hot water, the waste liquid from machine cooling systems, is used to produce the energy needed to heat the building. And the waste water arrives at the waste disposal system only after is has been completely cleansed of detergents, soaps and fine dust. And many more environment friendly features.

With it’s new manufacture Panerai has achieved another milestone in the brands remarkable history. We are thrilled by the motivation that Panerai combines innovative aspects with heritage without neglecting a modern view of economical responsibility.