Jaquet Droz celebrates its 280th anniversary, a great occasion to launch the Jaquet Droz Grande Seconde Skeleton One.

Time seems to stand still in ‘Vallée de Joux’, the high Jura valley of Vaud. The idyllic villages around the lake ‘Lac de Joux’ mainly live from dairy and their cheese. And watchmaking. From village to village on the eastside of the lake you can find old-fashioned houses next to imposing constructions of prestigious watch brands that obviously wanted to prevent the decay of time. The village of L’Orient is located in the southeast shore of Lac de Joux and at the same time home of the workshop of Breguet.

Looking back some years, the time for the once so flourishing Maison also seemed to stand still. Because after the death of founder Abraham-Louis Breguet in 1823, the innovative spirit of the ambitious inventor has not been promoted reasonably. Luckily there was Nicolas G. Hayek, the Swatch Group founder and quite possibly saviour of a watch brand that has a 245 year old (founded 1775) and strong heritage with many notable inventions. With this potential background, Nicolas G. Hayek in 1999 integrated the Groupe Horloger Breguet (to which the movement manufacture Lemania belongs) to the Swatch Group and laid the foundation stone for a new era. In 2003 Lemania was integrated into the Breguet SA and thus Breguet became a manufacture.

It’s mid-November and the Jura valley is already covered under a light blanked of snow. Pictures in the manufacture however give a disillusioning impression of how it can look up here in strong winter months. Then, this winter wonderland is hardly accessible – especially going back a few centuries without well-developed trade routes or any motorized transport. In the years between 1999 and 2013 major extensions of the manufacture were undertaken. Today, modern and classical elements merge together – in the front part of the building with the old workshop of Lemania and just behind the new and modern part of the manufacture with around 830 employees.

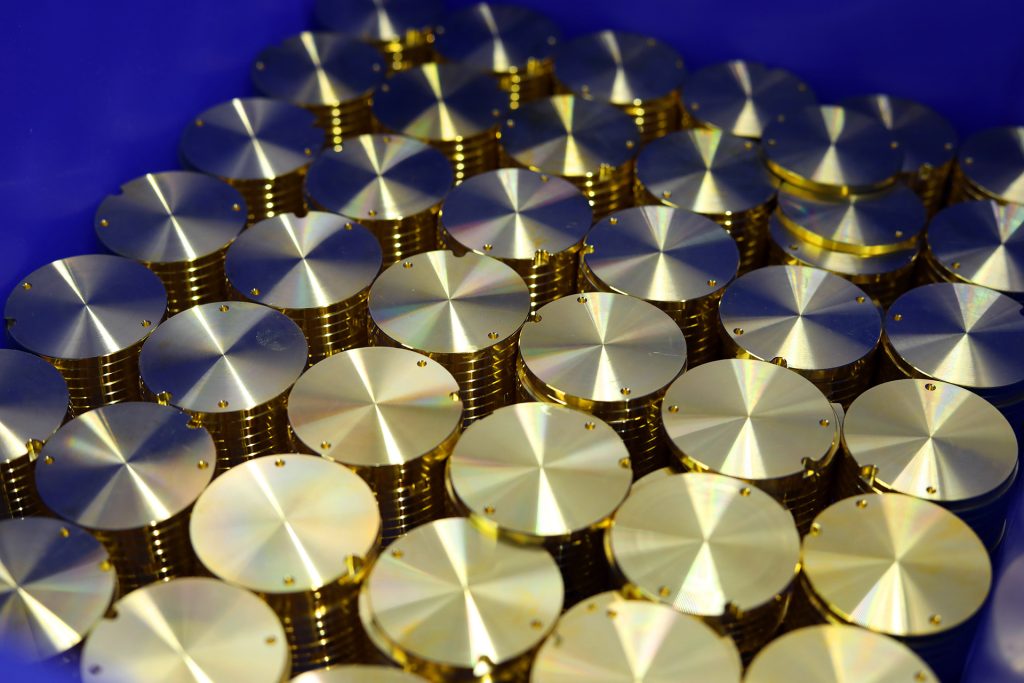

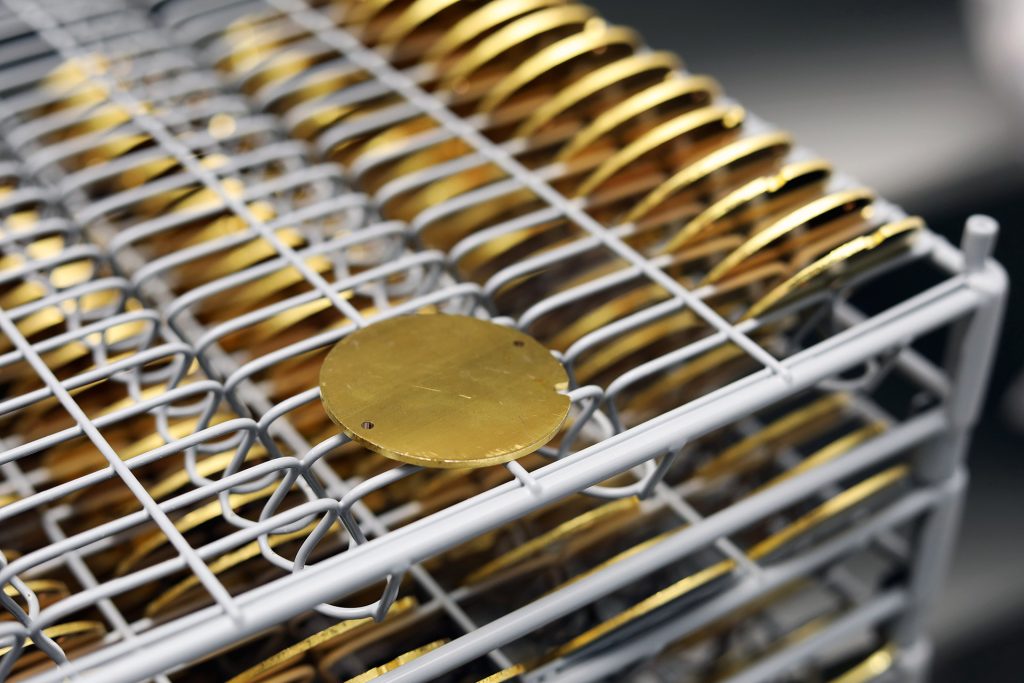

Here, all individual parts of a watch seem to play the main role. And thus the watchmakers take especially care of their protégés. But every protégés is a blank at first which needs to be shaped. Whereas the individual workshops were partly separated in the past, there is today a clear structure in the process of all working steps. To start with, all plates are being stamped from huge brass roles. The dedicated punching stamps are kept in the manufacture own archive. Breguet has access to 2.300 different punching stamps – some of them are still from Lemania times. In the dedicated department named ‘Stamping’ all blank movement plates are being made. They merely drill a few holes into them so they can be placed into the machines for processing.

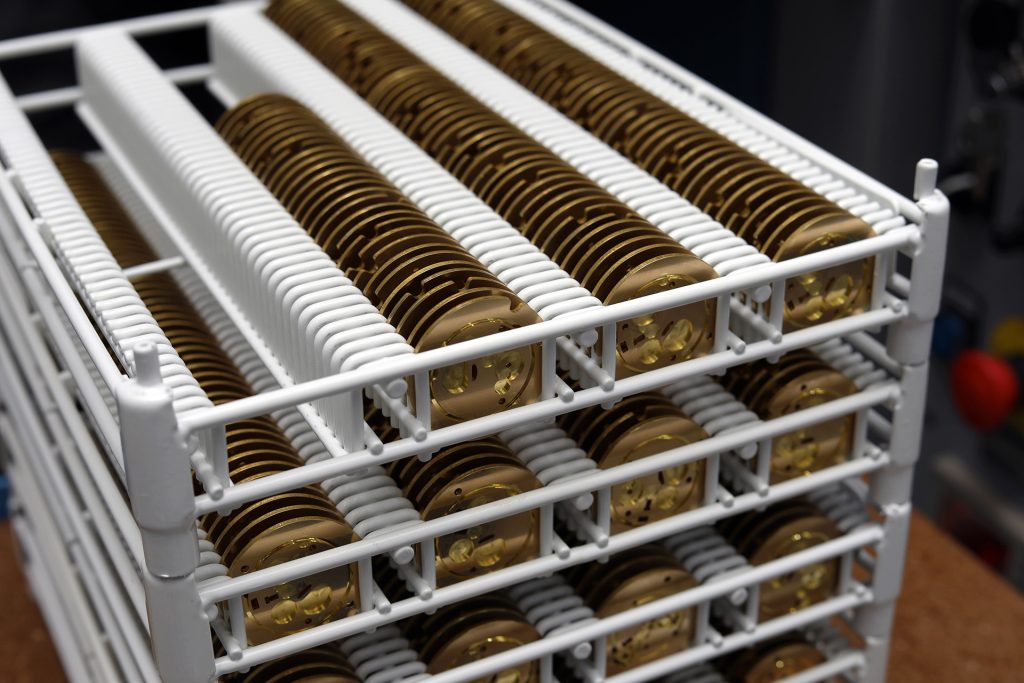

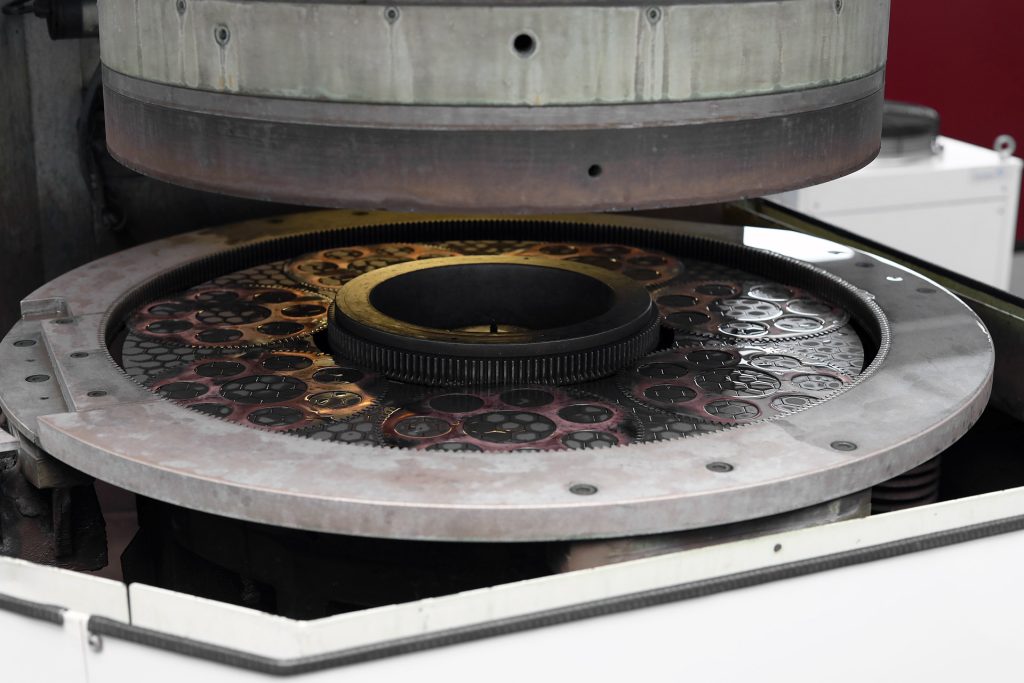

Now, all watch pieces take a bath before processing. Any impurities are being removed by a meticulous surface cleaning and at the same time parts are being polished individually. For this, copper, ceramic or even nutshells are added to the washing machines, pulverized or fine-grained, depending on a matte or shiny finish. All pieces come back here after every step.

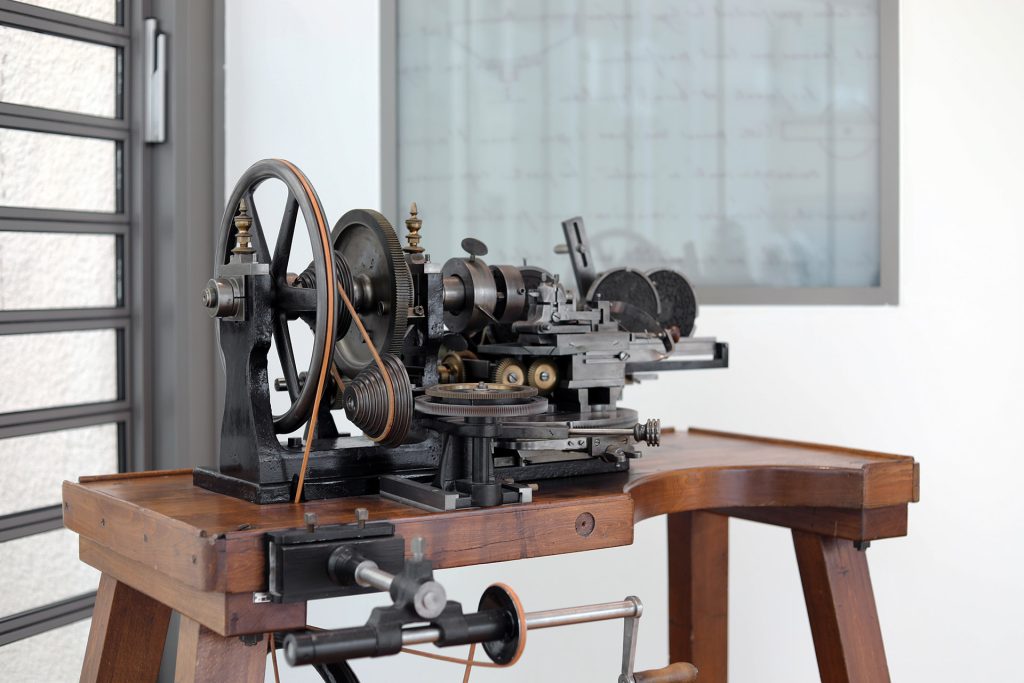

We start to realize the contrasts between the idyllic countryside and the manufacture life. For a short moment it is soothing to look through the window onto hilly fields where cows graze peacefully in the summer month and at this time, a magical fog creeps along the lake. On the contrary, it’s bustling and loud inside this part of the manufacture. Old machines merge with high-tech robots – to work as authentic as possible, Nicolas G. Hayek wanted to keep many traditional machines. The guilloche machines date back to the 1950s and were topped up by new ones.

In the next step the powerful robots come into action and rather seem to swallow the tiny pieces instead of treating them with highest attention and precision. They fine tune the pre-machined blanks and drill wholes or mill tiny particles from plates or other movement parts. Plenty of oil is constantly splashing behind transparent panels and ensures that all pieces are cooled down to prevent friction caused by the enormous heat and pressure. They basically work around the clock – if one fails in the middle of the night, the factory manager on duty receives a message on his phone. This is not what a restful sleep looks like, but the course of time takes its tribute.

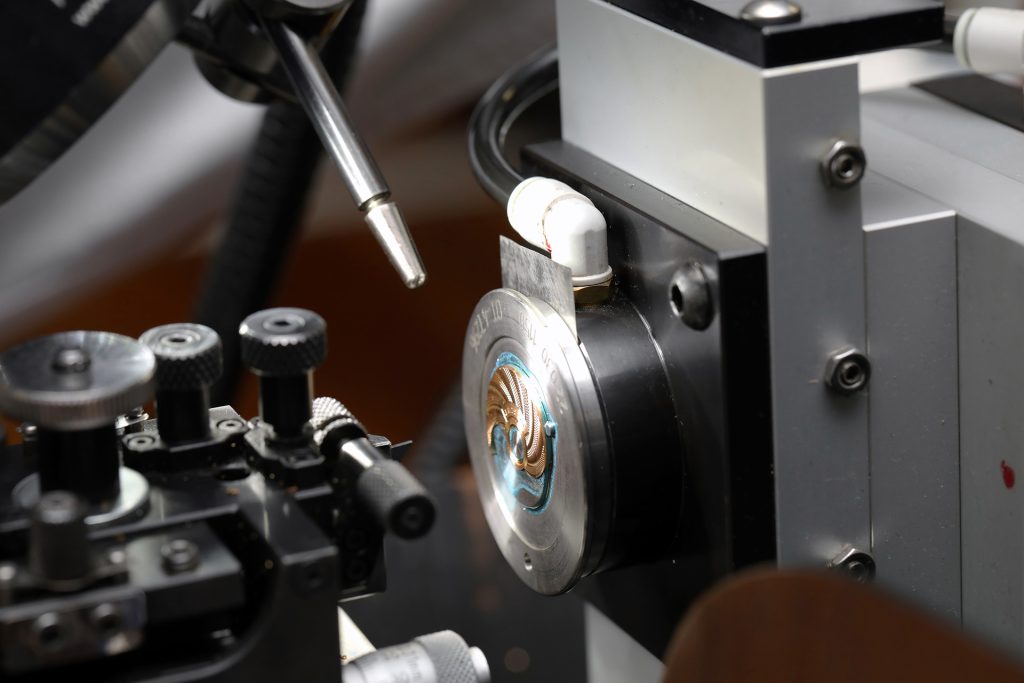

When visiting a manufacture, probably each department is equally appealing, apart from the fact that each working step is equally important for making a watch anyway. However there is one area that has a very special historical value for Breguet. Abraham-Louis Breguet was a master in the finishing of movement pieces and dials. Around 1786 Breguet began fitting his watches with engine-turned gold dials of his own design. Hand-crafted engine-turned motifs are one of the unmistakable hallmarks of a Breguet watch. Thus they still today pay special attention to this craftsmanship.

There are 35 restored and new guilloche machines in the department of ‘Guillochage’ on which 20 skillful and patient artisans turn the blanks into little pieces of art. This work is so detailed that they place the fine burin onto the plate with the help of a microscope. Here they guilloche decorative patterns like clou de Paris hobnailing, pavé de Paris cobbling, sunburst, barleycorn, waves, cross weave, checkerboard or flame into the blanks. The plates are mostly made of gold (and then silver-plated) – in some cases in mother of pearl which is even more challenging due to the delicate material. In this section of the manufacture the peaceful mountain idyll has got us back – the only noise comes from the rattle of the machines when they are re-adjusted by hand.

The masters of engraving sit just next door. Here they engrave all the motifs into dials, bridges and rotors. A very beautiful example can be seen on the backside of the Équation Marchante. There are hardly any pieces at Breguet that are not guilloched or engraved. Breguet has its own training program where the next generation of engravers try themselves on blank brass plates. To master the challenging Breguet lettering it takes a few months practicing.

The Breguet lettering and the model number are engraved by hand on nearly all watches. The best of them have been working in this field for 30 years and only they master some of the most complex techniques. By the way, many local families have been working for generations for the manufactures in Vallée de Joux and still do so today.

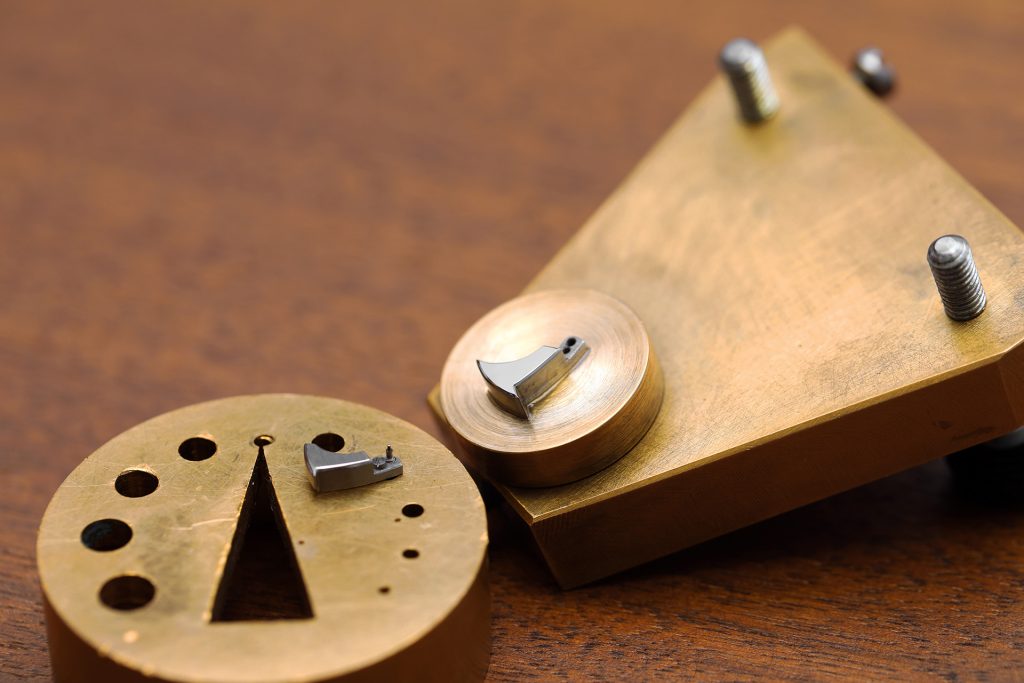

Going a few workbenches ahead we spot the craft of ‘Anglage’ being done on the movement pieces. When they have been stamped, rough edges have to be bevelled at an angle of 45 degree and polished with a metal rasp or wood and some grinding paste, depending on the desired finishing. For this process, Breguet has created a dedicated ‘Anglage’ department in the manufacture, which certainly exceeds the normal size compared to most other manufactures.

Breguet timepieces are distinguished by some more hallmarks. Besides the guilloched dials there are the typical hollow blue ‘Pomme’ hands. ‘Pomme’ (engl. Apple) comes from the round tops of the hands. Also Breguet numerals have a distinctive calligraphy that was designed by A.-L. Breguet himself. Just like nearly all parts at Breguet watches are being treated, some watch types have fluted case bands – fine grooves enhanced with double beading, all done by hand of course. As Breguet watches soon became a tempting target for counterfeits, A.-L. Breguet developed a secret signature in 1795 echoed into the dial and invisible unless the dial is examined in oblique light.

Besides these hallmarks Breguet also became famous for numerous inventions and patents. One of the most successful one was most likely the Tourbillon from 1801. Today, the manufacture is the world’s biggest producer of Tourbillons and possesses seven different ‘Tourbillon Families’, which are based on several types. And Breguet clients ask for innovation. Thus in the past years a few more novelties were added: instant-jump time-zone display, a magnetic pivot, running equation of time. They work a lot with silicon which is already in use for escapements, escape wheels and spiral springs. The Tourbillon cage is made of titanium.

The Head of the ‘Tourbillon Assembly Unit’ is responsible for the heritage and the innovations of all existing and new movements that are produced entirely in-house. He works for Breguet since 35 years and has not lost any enthusiasm for his craft. His favourite calibre comes from the ‘Extra Plat’ collection with an extra thin movement and a Tourbillon that seems to float of which he says: “It’s magical and at the same time minimalistic”. All the emotions that vibrate when he talks about the technology of all individual Tourbillon movements seem to affect the rotation of the tiny cages just by his presence. The sparkling in his eyes is reflected by the opulent steel of the movements – or is it the other way around?

As a triumphant finale the tour takes us through the Atelier of restoration. Robots have no access here – the small room is so traditional it might as well be a replica of A.-L. Breguets first workshop in Paris. One of the four watchmakers works on a pocket watch with minute repeater and an enamel dial from 1802. It belongs to an anonymous client and needs to be restored. It takes one single watchmaker between six and eight months to conduct all working processes on his own. If tools don’t exist any longer, they are being produced. Silicon springs, titanium and other modern materials are not being used – they try to work as true to the original as possible, to respect the horological heritage.

And then there is this very special and graceful table watch: the Breguet Sympathique N13. It is the number 13 of 20 existing pieces, which have been built since 1991. It is based on a design from 1793 of which A.-L. Breguet only built five during his lifetime. One remaining original piece belongs to the British royalty. What’s so special about this table watch is, that it automatically sets and winds a separate watch (wristwatch or pocket watch in past times) every two hours. It is attached on the top of the main dial – primarily during night time. Hence the name ‘Sympathique’ as two objects sympathize with each other.

With up to 767 different movement pieces and 13 stations with different working steps you can easily get confused. On monitors they are able to retrace where all parts are at a certain time and also how efficient the machines actually work. Abraham-Louis Breguet would have surely been happy about so much control. And even more about the number of watches that leave the manufacture in all the countries, thanks to modern technology.

Instead Emmanuel Breguet, his descendant and grandchild in the 7th generation can enjoy this success. He is responsible for the historical part of the brand since 1993. At lunch we talked about his book „Breguet – Watchmakers since 1775: The Life and Legacy of Abraham-Louis Breguet“ and the rich fund of old sketches, contracts, personal notes and pictures. Only due to the receipt of these witnesses he was able to reconstruct the brands history as detailed. Even today everything is filed in written form, not because Emmanuel Breguet doesn’t trust the digital technology but the written word has proofed to be reliable in the past centuries, a long period that the digitalization has not lasted yet, he points out with a chuckle. Better safe than sorry and hence everything is recorded in written and digital form.

If one would ask if the watches are manufactured by machines or by hand, there is one clear answer. Both. Every watch is unique in a way as the decoration is done entirely by hand – however little more precise then 200 years ago due to microscopes and computers that assist the artisans, but still unique. The mechanical course of time also helps to offer more precise timepieces to their customers. At Breguet however, certain processes will never be taken over by machines.