The Chanel Monsieur de Chanel Superleggera Bleu Edition is a limited-edition watch blending sports style with haute horlogerie.

Everyone forges their own unique professional path – and Pascal Narbeburu, current Timepieces Director at Van Cleef & Arpels, is no exception. His journey to the position is particularly interesting for two reasons. Firstly, he has worked exclusively for Richemont-led maisons that combine high jewellery and watchmaking: Piaget, Cartier and Van Cleef & Arpels. Secondly, he started his career in the automotive industry, where, the Swiss director tells me, he gained a penchant for efficiency. This highly focused approach has allowed him to elevate Van Cleef & Arpels’ watchmaking department to new heights ever since his arrival in 2016 – and as can be seen once again in this year’s Van Cleef Watches and Wonders novelties, which we covered in detail.

Automotive engineering is quite different from the luxury industry. At that time when I began, it was a period of revolution in creativity, particularly with the advent of computers and advancements in manufacturing processes, including CNC machining. However, from the beginning, my main interest lay in new concepts related to creativity, process organisation, and management.

My first experience in the watch industry was with Cartier in Geneva. Later, I moved to Piaget, where I continued working with high-end watches. I have always preferred environments with many possibilities, and Piaget’s history fascinated me. Around 1975 or 1976, I delved into high jewellery at Piaget, managing a team of 20 jewellers. Initially, each team worked independently, but over time, we realised the importance of collaboration.

Pascal Narbeburu, Van Cleef & Arpels Timepieces Director

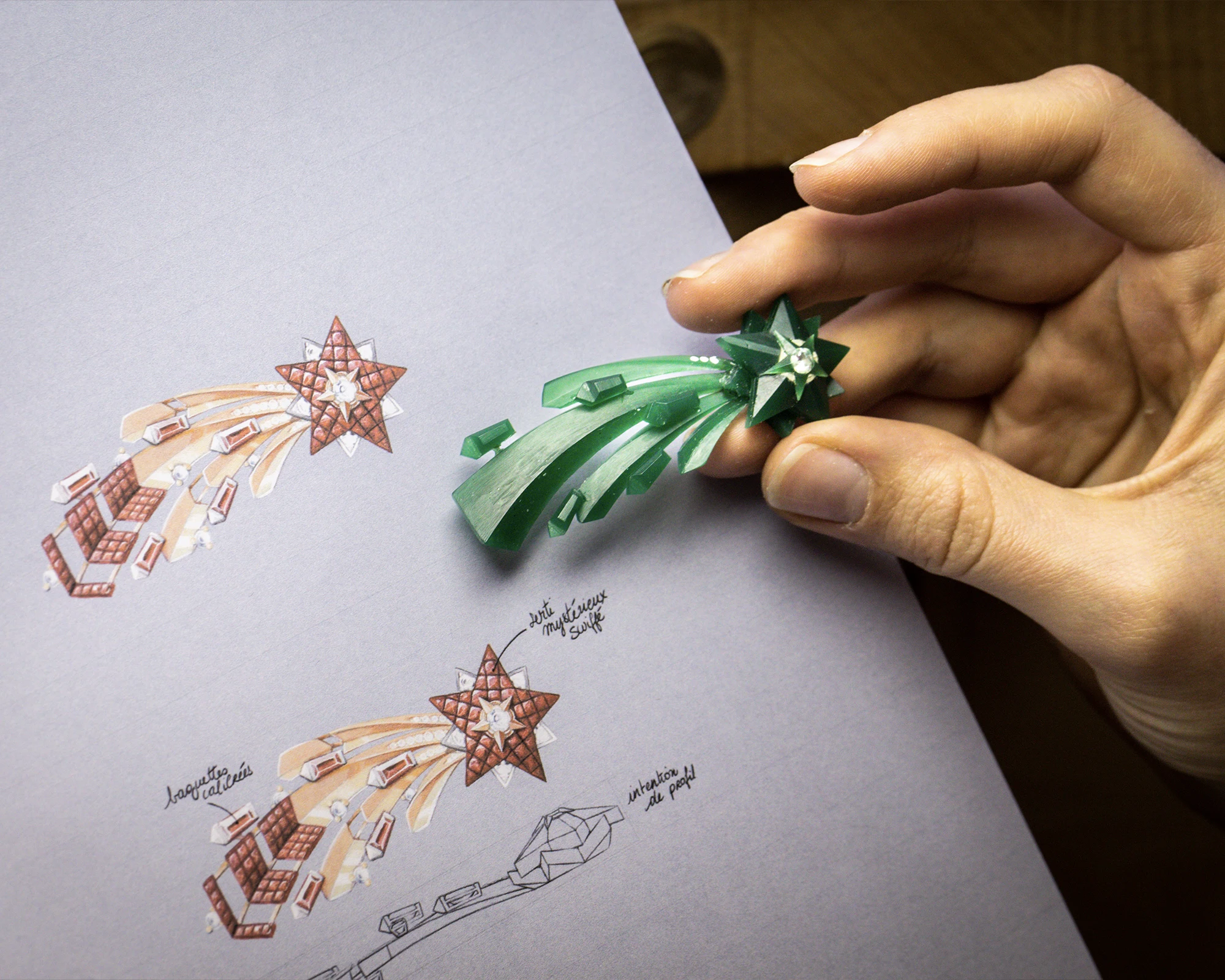

In 2007, we received our first 3D printer. I saw this new technology as an opportunity to rethink design processes in the luxury watch and jewellery industry. Instead of crafting entirely by hand, we could use computer-generated designs, print 3D models, cast them, and then refine them with traditional craftsmanship. I found an experienced jeweller – though, impressively, he was only 39 at the time – who was eager to be trained in digital design. This experiment proved successful, reinforcing my belief that nothing is impossible. In order to succeed, you simply need to provide a clear vision, explain your objectives, and find the right people willing to innovate. Over time, even sceptics were won over by the results.

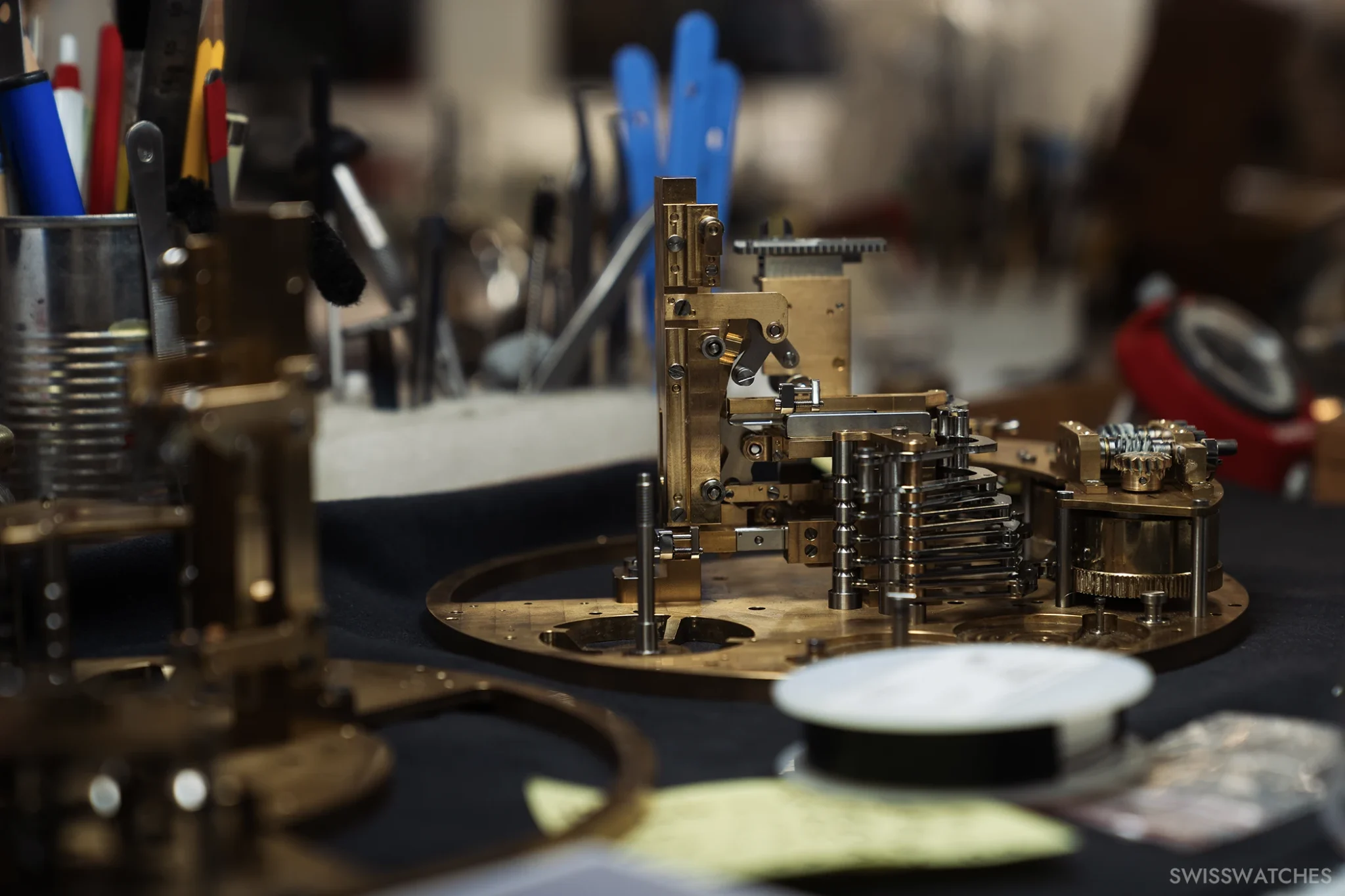

Regarding traditional craftsmanship versus modern technology: I prefer a balanced approach. Open-mindedness is essential in our field, because we frequently push boundaries beyond conventional norms. Unlike brands that focus solely on classic watchmaking, Van Cleef & Arpels always starts with a story, which drives us to explore new, unconventional solutions. Our skilled artisans must be adaptable, as seen in the development of this year’s planetarium. The artisans, who are more accustomed to working on small pieces, had to rethink their entire approach when we asked them to scale up to a much larger structure. The challenges were immense, requiring both technical expertise and an open mind.

For the planetarium, we collaborated with musician Michel Bosco to create unique melodies. Unlike traditional music boxes, we wanted a true musical experience, incorporating complex musical structures similar to piano compositions. This required precision in musical notation, ensuring the final result was both melodious and authentic.

We also needed custom-made bells, which led us to a historic German bell-making company dating back to the 16th century. Traditionally, they produced massive church bells, so when we showed them our miniature designs, they were initially sceptical. However, we insisted on using their traditional casting methods to preserve the authenticity of the sound. Working alongside a German university, we fine-tuned the bell shapes and acoustic properties, merging centuries-old craftsmanship with modern precision.

Collaboration is central to our philosophy. Unlike some manufactures who prefer to keep partnerships hidden, we proudly acknowledge and support our artisans. Our goal is to sustain and preserve traditional craftsmanship, ensuring these skills are passed down through generations. This was also the driving force behind Nicolas Bos’ vision when we created a unique piece in Paris. Initially, the goal wasn’t to sell it but to support the artisans. However, one of our clients was so captivated by it that they insisted on purchasing it. The media buzz surrounding the project was overwhelming, solidifying Van Cleef & Arpels’ reputation for innovation.

Given the complexity of our projects, maintaining coherence across multiple artisans is indeed a challenge. In the past, we faced difficulties due to the dispersed nature of our teams. In 2014, we addressed this by centralising expertise and virtualising our data. Seven years ago, I also advocated for virtualising mechanical engineering to strengthen the link between engineers and craftsmen. Now, they are able to work closely together, frequently collaborating to address constraints and challenges in real time.

This level of integration is crucial. In industries where production is siloed, such as book publishing, communication gaps can lead to suboptimal results. By contrast, our team of 120 people is highly engaged, working in unison, much like a rugby team supporting each other in every game.

Training is a vital component of our work. We have two schools in Switzerland – one for sculpture and one for enamelling. Currently, we have four apprentices, soon to be eight. Because our creations often venture into uncharted territory, we continuously train our artisans, ensuring they master new materials and processes. Even experienced hires undergo several months of training to align with our techniques and philosophy. For enamellers, apprenticeships last three years, while Swiss certification requires four years of training.

When it comes to future changes under Catherine Rénier’s leadership, it’s difficult to predict specifics. While we were saddened by Nicolas Bos’s departure, we are also excited about Catherine’s vision. She is highly intelligent and deeply understands the company’s spirit, making us confident about the future.

As for product development, I can’t disclose details, but our philosophy remains the same: starting with a compelling story, elevating craftsmanship, and integrating high-quality mechanical movements. This approach ensures that our watches continue to reflect the artistry and innovation that define Van Cleef & Arpels.