First released in 1983 and reissued just last year, the Rado Anatom serves as a bridge between the Swiss manufacture's past and present.

Richard Mille’s company history is marked by an unprecedented rise. In 2001, the first Richard Mille watch, the RM 001, made an immediate impact with its tourbillon regulator and a six-figure price tag, causing the brand to stand out from the crowd from the get-go. Almost as legendary was Richard Mille’s decision to throw the RM 001 on the floor at Baselworld 2001 in front of prospective dealers and partners to demonstrate its shock resistance. With the launch of the RM 001 and its tonneau-shaped case, the brand also gained its first distinctive characteristics, to which it remains true to this day.

RM 001, No. 001, around 2001

Credit © Christies

Today, with over 80 references and countless innovations under its belt, Richard Mille has established itself as a pop culture phenomenon and a symbol of extravagant wealth, through a series of collaborations ranging from tennis star Rafael Nadal to music producer Pharrell Williams. Characterised by the exceptional materials used in their construction and equally exceptional price tags, Richard Mille timepieces are more than just timekeepers: they are status symbols.

To understand who is responsible for Richard Mille’s occupation of a very special position at the top of the Swiss watchmaking hierarchy and how the numerous horological innovations have come about, I set out to take a look behind the scenes and meet the people who make it possible. Join me on an exclusive journey into the inner workings of the Richard Mille manufacture.

With Neuchâtel as my starting point, my journey takes me along snow-covered mountain roads lined with small villages and scattered farms. After travelling 40 kilometres and climbing 559 metres in altitude, I finally reach Les Breuleux, which is covered in snow in the middle of the Jura mountains.

It is an inconspicuous place that, in addition to a school, a small railway station and a church, hides a decisive detail that sets it apart from other villages in the Swiss Jura: the Richard Mille manufacture. An annual production of 5,600 watches (2023) comes from this village of 1,611 people, which catapults Richard Mille to sixth place among Switzerland’s top-selling watch brands with a total turnover of 1.54 billion Swiss francs (2023). Guenat S.A. Montres Valgine, the first of which has been in existence for 110 years in Les Breuleux and the second of which opened its doors in 2013, currently employs 215 people in two manufacture buildings. They are responsible for grinding, polishing and assembling the components for the brand’s impressive 14 in-house movements.

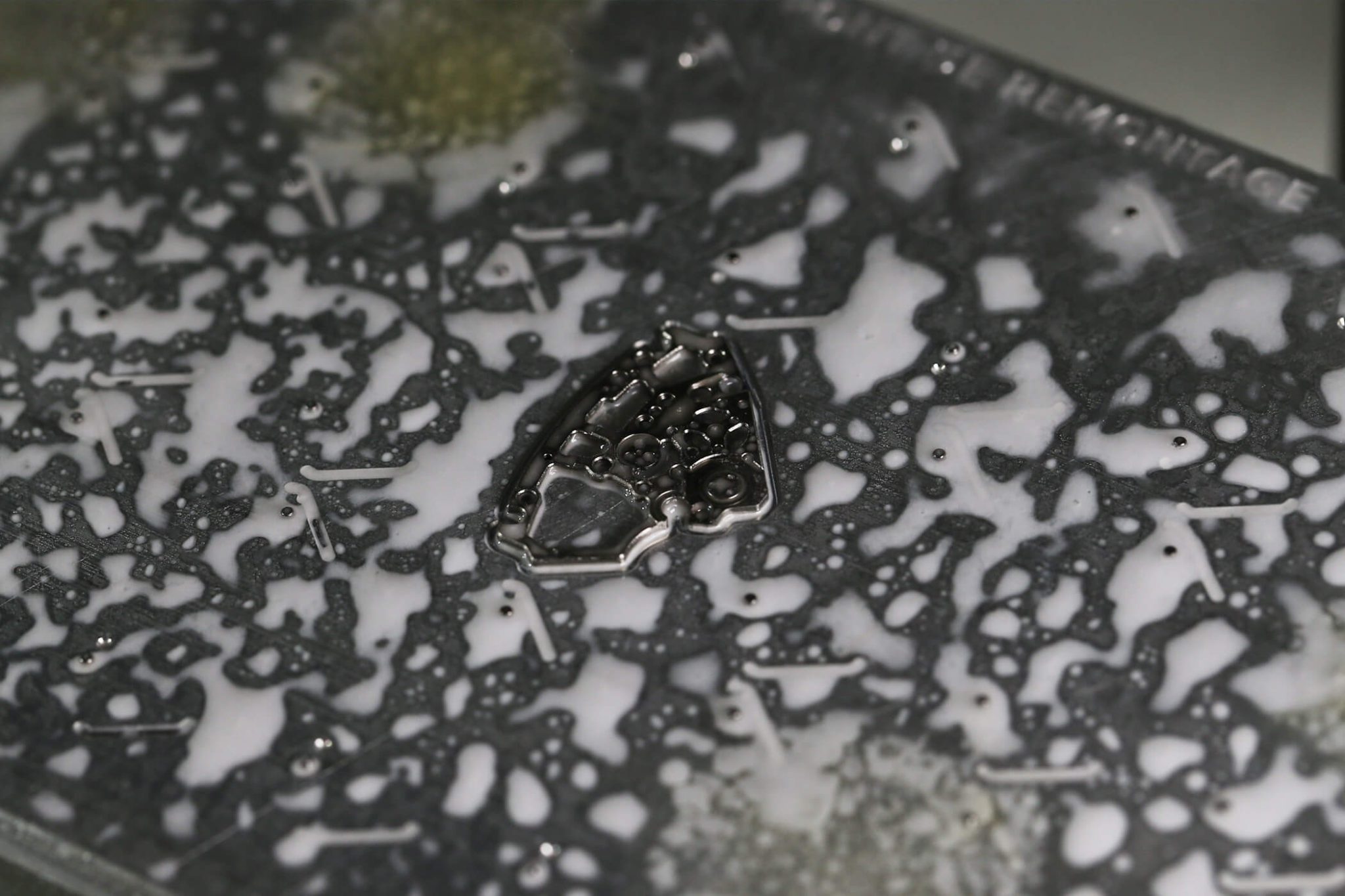

I start my tour of the Richard Mille manufacture in the first manufacturing facility, which specialises in the production of Richard Mille cases and a range of movement components, including main plates, bridges, screws and some wheels. Man and machine work side by side in the clinically clean production hall, where even the slightest impurity poses a quality risk. The machines, which are equipped with diamond tools, are programmed by the employees to meet the specific requirements so that they can finally begin their work of cutting out housing parts. In the case of the RM-UP 01 Ferrari, the watch that until a few weeks ago held the coveted title of the world’s thinnest watch, it took a whole year to find a solution for the production of the case.

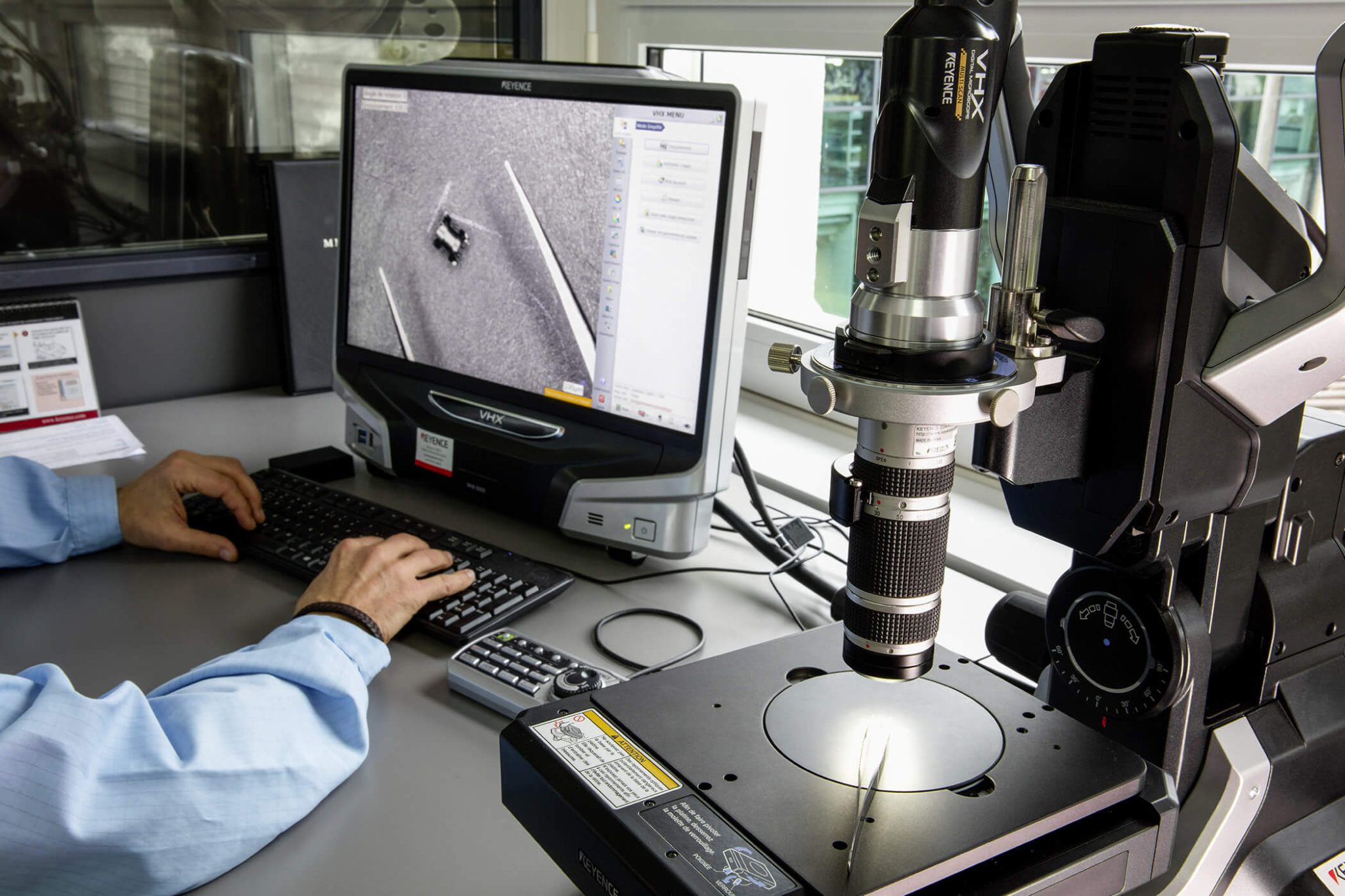

Around 80% of the cut-out housing parts have to be reworked by hand before they are finally subjected to a series of fine grinding and inspection processes, the final inspection stage of which has a tolerance range of 0.0003 mm. By way of comparison, a human hair has a diameter of around 70 micrometres. For the inspection, the respective housing part is placed under a microscope and ground until every detail matches a template.

Richard Mille has always mastered one thing better than almost any other brand: producing a watch that is technically sophisticated, full of high-tech materials and, thanks to a consistent design philosophy, recognisable in the blink of an eye. Above all, however, it is innovations such as the RM 27-04 Rafael Nadal with its skeletonised movement, which allows the calibre to float in its case and withstand accelerations of over 12,000 G’s, that make the brand so appealing.

Inspired by the strings of a tennis racket: the RM 27-04 Rafael Nadal

To achieve this, Richard Mille relies on the expertise of many different specialists, just like Formula 1 teams, as the tiny components require a precision and knowledge that can only be acquired and perfected through years of experience. The watches should therefore be seen as a joint endeavour that not only incorporates the skills of the company’s own employees and watchmakers, but also those of external material suppliers and mechanical engineers. For this reason, the Richard Mille manufacture uses a hybrid system in which it produces a large proportion of its requirements itself and purchases the rest from selected partners.

The decisive criteria for selecting a partner are flexibility, production capacity, and, above all, regionality. This is primarily due to the fact that quality-relevant parts and components that require a high level of manufacturing expertise must be available quickly and flexibly in order to avoid a production backlog.

This is particularly evident with the supplier of Carbon TPT® and Quartz TPT®, North Thin Ply Technology (NTPT), which is only 1 and a half hours away and in which Richard Mille is a major shareholder. Developed exclusively for Richard Mille, Thin Ply Technology was first introduced into the Richard Mille universe with the launch of the RM 27-02 Tourbillon Rafael Nadal in 2015 and has been used in the brand’s watches ever since.

Carbon TPT manufacturing process: Thin carbon fibre layers are stacked at 45 degrees to the previous layer and pressed under pressure and heat

This concept was further refined with the introduction of the RM 50-03 in 2017. This time, not only were titanium and Carbon TPT® used in the construction, but a completely new material was also introduced: Graph TPT™, better known as graphene. Graph TPT™ is distinguished by the inclusion of graphene, a material that, according to Richard Mille, is six times lighter and 200 times stronger than steel. As a result, the RM 50-03, including its strap, weighed less than 40 grams and was, at the time of its launch, the lightest mechanical chronograph ever made.

These new applications for graphene are the result of research at the National Graphene Institute, which was founded at the University of Manchester in 2015

Stettler in Lyss, the supplier of sapphire, is also only 41 minutes away by car. This special material, which is used in the brand’s most expensive models, takes a full 40 days of work, followed by 350 hours of polishing, to turn a sapphire block into a sapphire case. It was not without reason that the RM 52-01 Skull Tourbillon – ‘Vanitas Vanitatum’, a watch with an impressive skull design and transparent case, achieved a record result of 6,661,098.26 Swiss francs at the auction on 19 July 2022 at the renowned Antiquorum auction house in Monaco.

RM 52-01 Skull Tourbillon, also called ‘Vanitas Vanitatum’, unique piece

Credit © Antiquorum

However, this regionality does not end with the materials, but is also reflected in the employees and trainees. Of the five watchmakers currently completing their four-year apprenticeship at the Richard Mille manufacture, most come from Les Breuleux. In addition, Richard Mille only accepts apprentices from public and local Swiss schools, as the considerable duration of the four-year apprenticeship and the training at the manufacture’s headquarters require them to live in Switzerland and especially in the neighbourhood. Richard Mille also has an apprentice workshop where the trainees are taught by experts.

Richard Mille is particularly proud of the fact that the components of a watch and the associated services have an in-house production rate of 80 percent. At Richard Mille, “do it yourself” means covering pretty much every service that is part of its core expertise, from concept to end product. The spectrum ranges from case assembly and aesthetic control to crash tests, all of which are carried out in the manufacture. Each station begins its work seamlessly where the previous one left off.

One of the results of this is that the now 14 in-house calibres, the first of which was introduced in 2012, are manufactured to a high standard yet also economically thanks to selected components and in-house assembly – more on this in a moment. Interestingly, there is another in-house calibre, the RMS05, which does not display the time and is used in the Richard Mille ‘Fountain Pen’, which is why it is often mentioned separately. To cope with the annual growth in watch production (5,900 watches are forecast for 2024), Richard Mille takes over 60% of its movement production, while the remaining 40% is supplied by Manufacture Vaucher and APLL.

The extension of the first manufacture building inaugurated in 2020, which houses the artistic direction, the research and development team and the technical offices, i.e. movement and case engineers, also enables an even better dialogue between developers and watchmakers, which inevitably optimises many processes and generates ideas. This dialogue is necessary because a Richard Mille watch takes between three to five years from design to completion, depending on the complication. During this time, it and its components are moved from station to station, polished, assembled several times and readjusted. This process in particular does not always go smoothly, as one watchmaker told me. A watch may travel back and forth between the various stations up to seven times before it finally meets the requirements – a process that requires teamwork and, above all, synergy between the departments.

The facility, which opened in 2020, houses the technical offices, in particular the case and movement engineers, the research and development team and the artistic management

These synergies, which today form such a crucial part of the brand’s successful concept, go back to the very beginnings of Richard Mille. In 1999, the creative Frenchman Richard Mille, who relied on his intuition, and the technically minded Swiss Dominique Guenat joined forces to found the brand that is so well-known today. Both, who believed in cultural exchange, brought their respective strengths and skills to the partnership.

The man behind the brand: Richard Mille

In 1991, Dominique Guenat took over the management of Guenat S.A. Montres Valgine, a company that has been based in Les Breuleux for over 110 years and has experienced the evolution from mechanical movements to quartz movements and back again. Today, Richard Mille movements are produced exclusively in four different areas in the second factory building, which has been in the family for three generations. Following the traditional Swiss watchmaking method, in which specialists are employed exclusively in their area of expertise, the bridges and mainplates are first pre-assembled.

In the next section, a watchmaker receives a set of components to pre-assemble the movement. After successful testing, however, the movement is disassembled again for cleaning. In principle, all of the manufacture’s watchmakers can assemble the 14 in-house calibres. One exception, however, is the first in-house chronograph movement, which was introduced in 2020 in the form of the RM 72-01 Lifestyle Flyback Chronograph. Due to its complexity, it can only be produced by a few specialised watchmakers.

The RM 72-01 Le Mans Classic: an exclusive model to mark the 100th anniversary of the Le Mans 24-hour race

In the next section on the second floor, the movements are finally brought to life by assembling them, inserting them into the case and setting the hands.

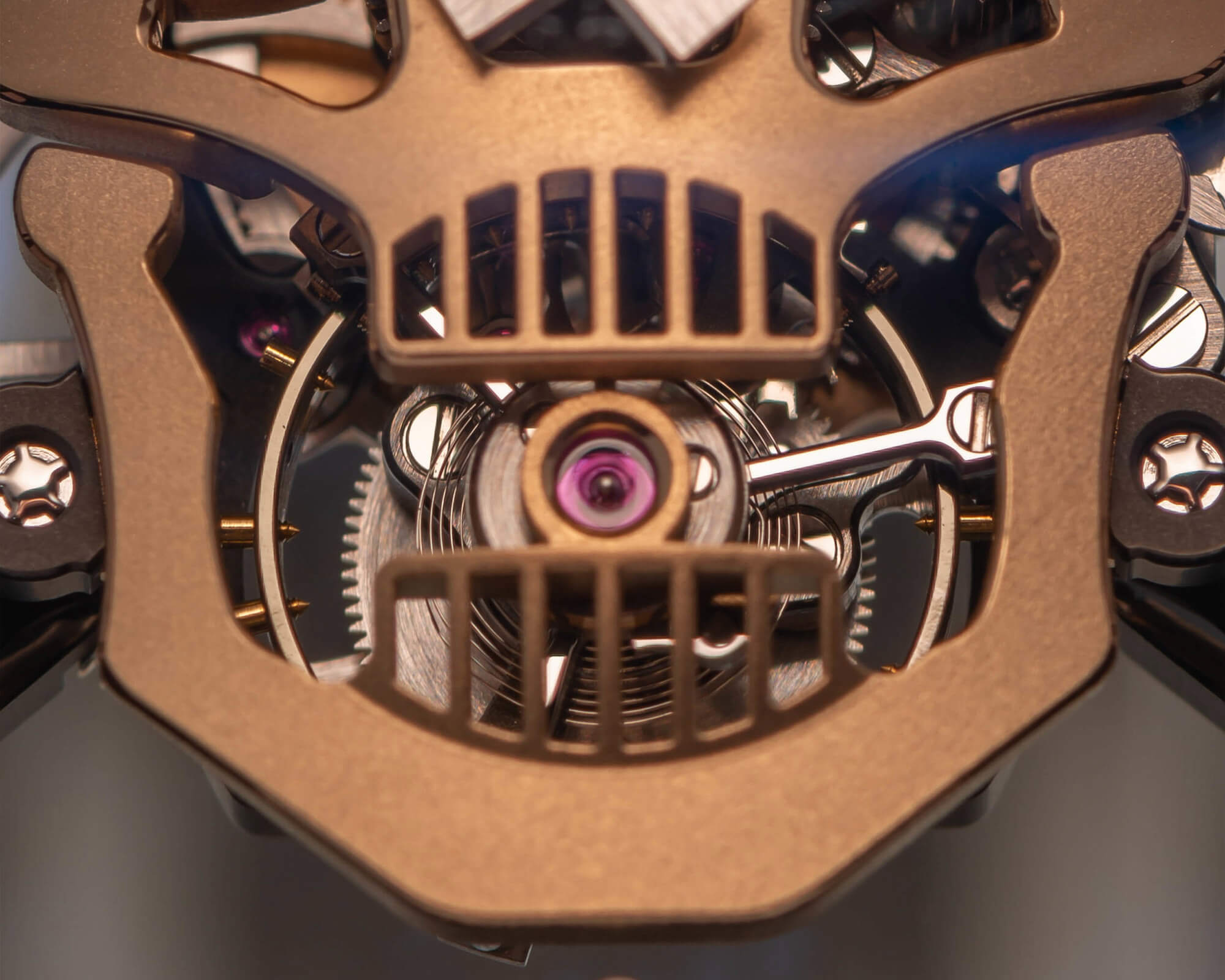

One particular exception, however, is the tourbillon, a mechanical device developed by Abraham-Louis Breguet in 1801 to minimise the effects of gravity on the accuracy of pocket watches due to the constant rotation of the balance and escapement. In modern wristwatches, on the other hand, the natural change of position due to wrist movements means that the effects of gravity are less of a problem and the tourbillon is now seen more as a demonstration of craftsmanship.

At Richard Mille in particular, tourbillons are considered a central part of the brand identity, as they are also integrated into sports watches. This is unusual in that tourbillons have traditionally been seen as delicate devices. However, with timepieces such as the RM 009 Felipe Massa Tourbillon, which weighed just 29 grams without a bracelet – a world record at the time – the brand swept away any doubts and paved the way for lightweight tourbillon watches that have become synonymous with the brand today.

RM 009 Felipe Massa Tourbillon, Prototype No. 3, circa 2005

Credit © Christies

This is why the tourbillon is considered the supreme discipline of the manufacture, reserved for only a few watchmakers. To achieve near perfection, three specialised tourbillon watchmakers work on a single piece for an average of three months. Each of these watchmakers is responsible for a single tourbillon and sees it through from initial design to completion.

This complex process, which alone takes six weeks to fit the tourbillon device to the movement, ensures that each part fits the movement like a tailor-made suit that fits the body perfectly. Once the tourbillon is running smoothly, however, the work is not yet complete. After this first phase, the entire movement is taken apart again, every part is cleaned and all the oils are changed, just as you would drive a new car carefully for the first few months and carry out regular checks. Richard Mille receives support from Audemars Piguet (AP) to ensure high quality and precision.

After my visit to the Richard Mille manufacture and the question posed at the beginning about how the brand’s unprecedented success came about, it is clear that both human and technical factors play a decisive role. Emotions and passion were of decisive importance from an early stage, namely with the first Richard Mille watch. Even then, the watches were seen as the culmination of Richard Mille’s personal passion, racing, which gave the watches the slogan ‘Racing machine on the wrist’ and formed the brand’s identity. On the RM 001, a ‘Torque Indicator’ as a power reserve indicator revealed his connection to racing. Today, as Richard Mille slowly retires from the company and his children take the helm, he devotes himself entirely to this passion. As the main sponsor of classic car events such as the Le Mans Classic 24-hour race and the ICE race in St. Moritz, he supports classic cars, teams and drivers.

The Le Mans Classic 2023

One lasting impression that stayed with me after my trip is the family feeling that extends from the creative offices to the watch workshops. The strong team spirit and the predominantly young team – many of the employees are former school friends – enable the Richard Mille manufacture to operate outside the usual industry standards. This young dynamic is also a source of creativity, which is reflected in the aesthetics of today’s models: modern timepieces, although they differ from the originally established RM 001 design language, nevertheless remain closely linked to it. Increasingly, artistic, colourful but no less technically impressive watches are leaving the manufacture, such as the RM 88, an emotionally charged watch that could have fallen out of an emoji world, or the RM S14, a talisman that combines the aesthetics of a contemporary Richard Mille timepiece with those of an antique relic. The never-ending demand proves this strategy right.

The RM 88 Automatic Tourbillon Smiley, limited to 50 pieces

On the technical side, the high vertical range of manufacture of 80 percent contributes significantly to the company’s success. This allows Richard Mille to ensure internal quality standards, utilise the expertise of its employees profitably, and keep it within the company. Through constant dialogue between the technical office and the employees on the factory floor, processes are continuously developed and optimised. This combination of internal expertise and creative team spirit ensures the future viability of Richard Mille and makes the brand largely independent of external suppliers or experts.