The Munich TAG Heuer Boutique shines in a new splendour and offers a youthful and energetic approach.

When one thinks of Swiss-made watches, what springs to mind? For some of us, it’s a luxurious boutique in the heart of an affluent metropolis. For others, it’s a fast-paced car rally with watch-branded banners plastered over the track. But what about the place where mechanical watches come to life? To find out, I accompanied horology house Blancpain on a journey to see the place where the very foundations of Swiss watchmaking were first laid, and uncover how the brand has carried these long traditions through the centuries.

Blancpain can be credited as the oldest Swiss watch manufacture still in business. Its founder, Jehan-Jacques Blancpain, first registered himself as a watchmaker in the small village of Villeret in the Vallée de Joux in 1735. To this day, the scenic Vallée de Joux is revered as the historic heart of Swiss watchmaking. Centuries ago, local country-dwellers working as farm labourers during the summer months would turn to watchmaking in the winter, creating tiny components for neighbouring manufactures. Many of these locals had fled across the border from France, as Huguenots continued to face persecution during the Wars of Religion. Crucially, many of them came equipped with watchmaking expertise; something that proved decisive in the development of Switzerland’s horological heritage.

Even today, a stroll through the Vallée de Joux with its lush green pine trees and grazing cows often gives way to ancient farmhouses-cum-watch-manufactures, featuring large doors for cattle downstairs and a long row of small windows on the upper floors. These characteristic windows were essential for capturing the light that would allow locals to work on mechanical watch components for as long as possible throughout the cold dark days of Swiss winter.

Over the decades, watchmaking at Jehan-Jacques’ workshop slowly but surely developed, all while remaining a family business. Jehan-Jacques’ grandson, Frédéric-Louis, marked the first company milestone by upgrading the workshops and reviving an interest in escapement design by introducing a modified escapement alongside an ultra-thin construction in 1815. In turn, Frédéric-Louis’ son, Frédéric-Emile Blancpain, rechristened the company ‘Fabrique d’horlogerie Emile Blancpain’ in 1830. By this time, the industrial revolution had fully taken hold in Switzerland. The company would soon become the largest watch manufacturer in Villeret.

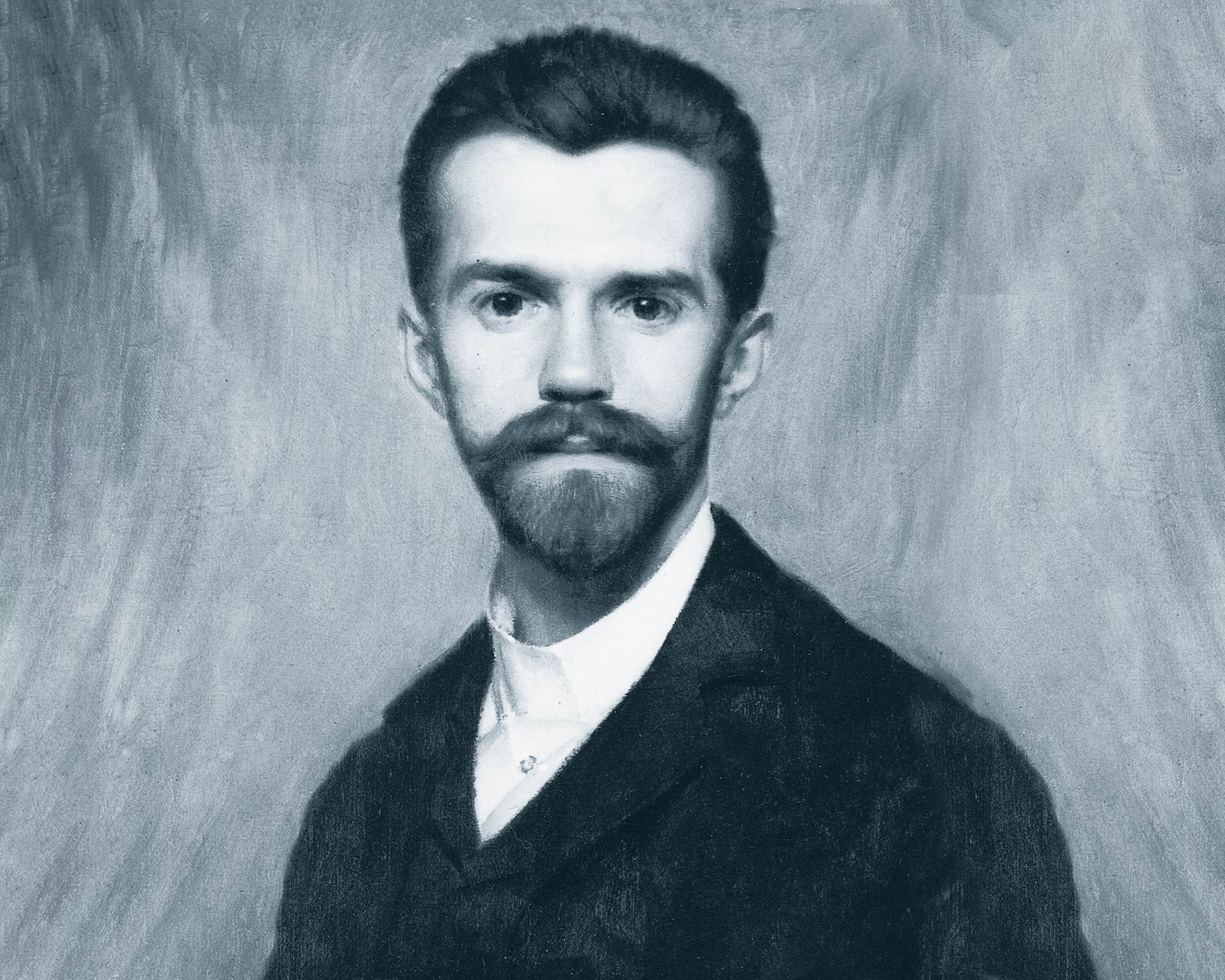

It was a person from outside the family, however, who proved definitive for the future of Blancpain. In 1859, the widely esteemed craftsman Louis-Elysée Piguet transformed a mill in the neighbouring village of Le Brassus into a workshop. By this point in time, locals were not only providing single components, but entire ébauches(movements) to manufactures. Louis-Elysée Piguet was one such supplier. His workshop would later become one of the founding branches of Blancpain.

It is here, in this old mill, that Blancpain’s complicated watch workshops and Métiers d’Art are now located. It is one of two of the main bases responsible for producing Blancpain timepieces. The other principal branch is the Le Sentier workshop, located deep in the Vallée de Joux, and where the brand counts over 700 employees in its workforce.

That said, it is worth mentioning that a Blancpain watch finishing division has existed in nearby Delémont, in collaboration with a long-standing partner of the Swatch Group, Simon et Membrez SA, since 2022 – Blancpain joined Swatch Group way back in 1992, when it was still known as SMH.

Our tour of the manufacture commences at the Le Sentier workshop, which can claim much of the credit for Blancpain’s impressive in-house production processes. The site is also the brand’s most historic location, as it was here that Jehan-Jacques first registered as a watchmaker.

Photography, alas, is strictly forbidden in this heavily industrial area of production; and to be clear, this is no high watchmaking facility. Rather, this is the place where the very base materials start their metamorphosis into becoming luxury watches – including, I observe with interest, for other brands, both in and outside of the Swatch Group. Phenomenally heavy rolls of material – brass, gold, platinum, steel, titanium – are stacked upon carefully labelled shelves. Arriving as formidable quantities of raw material and swiftly turned into blanks, they will leave the manufacture as tiny pieces that play a vital role in a mechanical watch’s performance.

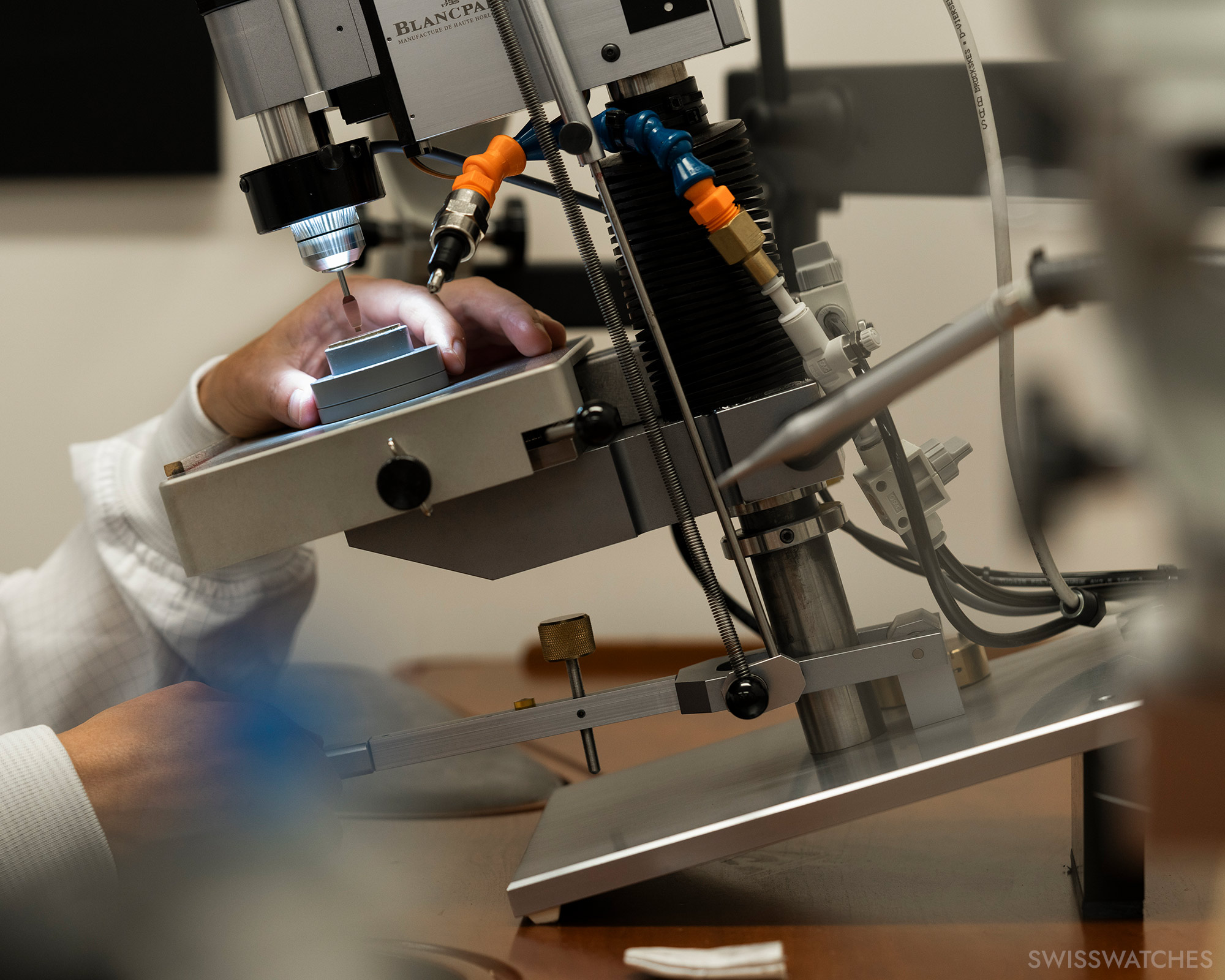

Another surprising fact many may not know about the Blancpain Le Sentier base is that not only are the movement components made here, but also the tools for doing so. This applies to even the smallest of pieces, carefully crafted to microscopic precision. We pass by one employee who works with metal with a thickness of 0.03 mm – aka thinner than hair. Overall, we learn, Blancpain is a master in the field of micro-engineering – and home to over 10,000 of its own tools.

Nothing at the plant is wasted: shavings produced throughout the processes are recycled and used again. As well as being sustainable, it would make little economic sense to do otherwise. After all, typically speaking, employees will start working with 15g gold and end up with a component weighing a mere 1.5g.

Throughout the manufacture, the blanks will go through numerous processes that will see them be cut, stamped with holes, and shaped until they form the crucial components necessary for the corresponding calibres. From base plates, rotors, anchors and pallets to wheels: every part is made by Blancpain right here. The rotors, by the way, are almost always in gold – or, upon rare occasion, platinum. The calibres in the Ladybird models, for example, tend to use platinum to compensate for their dainty size.

Thick brass components and thinner elements for bridges and springs lay side by side; heavily stamped components will soon be meticulously decorated by hand over several hours. This blend of modern and traditional methods is what sets Blancpain apart.

This brings us to the Le Brassus location, which is where one can truly find Swiss watchmaking as we all envisage it: tranquil, traditional, and sleepily located against the backdrop of a pine tree forest, with rolling hills to the left and gushing rivers to the right. It is here that Blancpain’s master watchmakers work on the highest of complications and unique customised models, as well as playing host to a suave wooden-clad showroom, as well as a specialised workshop dedicated to vintage models looking for some TLC.

Upon entering the Le Brassus farmhouse, guests are immediately treated to a view of some of the most incredible Blancpain creations of all time: from tiny Ladybirds, to the 1930 Rolls (aka the first self-winding wristwatch for women) to the original Fifty Fathoms, which we were lucky enough to get our hands on for shooting.

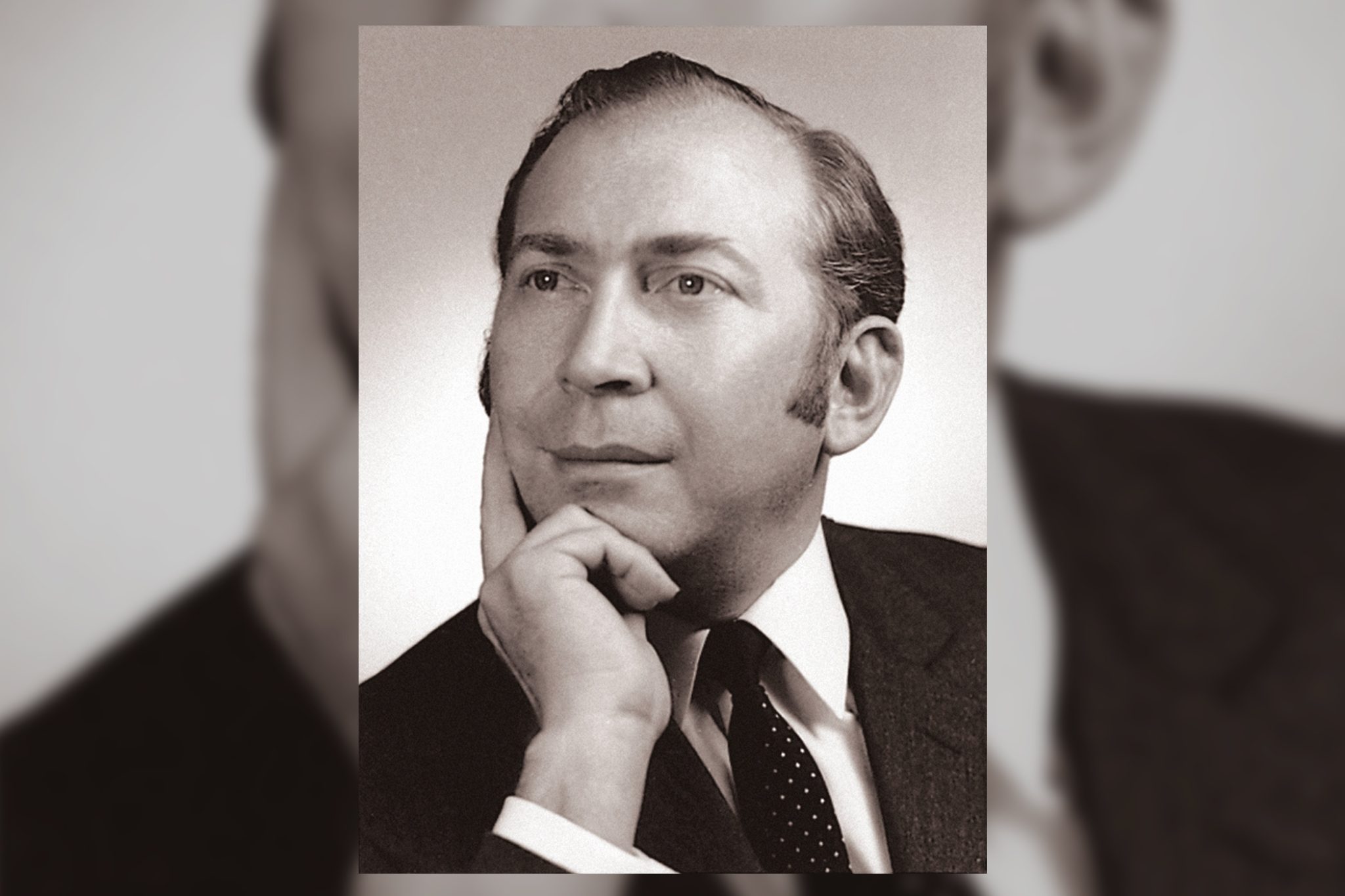

The latter, of course, is Blancpain’s ground-breaking diving watch that put the brand on the map as not only a manufacture with aesthetic finesse, but also the utmost technical expertise as they launched the world’s first diver’s watch with a scale on the bezel under legendary then-CEO, Jean-Jacques Fiechter.

It’s impossible to report on Blancpain as a ‘Manufacture de Haute Horlogerie’ without first mentioning the Grand Complications atelier. After all, it was here in Le Brassus that Louis-Elysée Piguet set up his workshop specialised in complicated movements. As mentioned, in 1891, Louis-Elysée Piguet bought an old mill, then known as ‘Le Moulin’, on a hillside just above the village of Le Brassus.

Today, Blancpain dub this production location as ‘The Farm’ – and it is here that Blancpain’s master watchmakers devote themselves to the grand complications, from minute-repeaters and split-seconds chronographs, to phenomenally impressive carrousels, tourbillons and ultra-complex calendars – including my personal favourite, the Calendrier Chinois Traditionnel, which is given a mention here. One of the most fascinating parts of our tour is seeing how perpetual calendars, which are often limited editions, are made user-friendly and secure. The watches are carefully and innovatively designed to prevent end customers from damaging the movement by making incorrect settings.

The precision required for assembling components in general, let alone this highly specialised atelier, is astonishing. For example, the escapement wheel, which regulates the movement, has to be seated with an accuracy of around three microns (one millionth of a meter). This level of precision is essential for the reliable operation of the mechanical watch.

The Farm is also home to the manufacture’s finishing department, and herein lies another charming fact: when finishing movement components, Blancpain still works with gentian, a plant that is local to the Vallée de Joux. Also known as the ‘yellow fairy’, its supple, dense stem makes it an ideal tool for polishing watch components. The rest of the plant is used to create essential oil and, as is proudly laid out in a small bottle in the workshop, a local liqueur. Wood shavings cover the atelier floor of this bright windowed attic of the farmhouse, as each artisan carves their own gentian tool to fulfil their client’s needs with the help of fragrant lavender and almond oil.

Let’s take a good look at the customised models, as this is an area in which Blancpain truly excels. The most infamous, perhaps, are the libertine timepieces that emerge from its minute repeater department, a small room that plays host to a world of fantasies for Blancpain’s more adventurous collectors. Here, quiet, classical-looking Villeret models can be turned over to reveal chiming and automaton watches, custom-made to perform specific erotic acts varying in position, genders, numbers and backgrounds. It’s actually a pretty historic genre, with erotic watches having enjoyed a heyday during the reign of Louis XV. Today, however, they’re a rare find, with only a few other traditional watchmakers such as Ulysse Nardin specialising in the field. Other automaton models opt for more vanilla artistic visions, such as a golfer taking a swing.

Those less sensually inclined can alternatively turn to Blancpain’s Métiers d’Art workshop – and it was this department that truly blew me away. Here, mechanics move aside in favour another form of art and craftsmanship; Blancpain’s artisans carefully create miniature artistic wonders using the likes of fine hand engraving, cloisonné and champlevé enamel, as well as Japanese shakudō, binchōtan and damascening techniques.

One of the serene young women working in this department tells me she didn’t study watchmaking, but rather art, before coming to the manufacture. Huge red dictionaries specialising in the likes of Asian art and culture tower across the neighbouring office shelves by the workshop, conjuring up images of serenely swirling koi and ethereal gardens. Others opt for more religious motifs; the woman I speak to is working on etching out the engraving of what appears to be Hindu god and giver of good luck, Ganesha.

Creating one single watch can take well over six months. Therefore, some clients, the employee informs me, like to receive updates and photos from the craftsperson throughout the process, while others prefer only to see the final product.

Finally, we end our tour (if we omit a magnificent lunch of local produce) at what is surely the most inspirational location in the manufacture: the heritage workshop. What we see here is nothing short of incredible. From rare Fifty Fathoms to heavily oxidised military watches telling tales of radium lume, we come away with the knowledge that nothing is too much of a challenge for this department.

Some watches here may become residents at the manufactures for many months – but the authentic, highly precise level of restoration is second to none. Wherever possible, watches are restored using the original methods, even for watches nearing half a century old. This philosophy ensures that watches remain authentic and, as is particularly important for Fifty Fathoms and other such military watches, retain their value. As the head of the department articulates, ‘We don’t make anything new in our department. We want everything to stay the same.’ With three main servicing options on offer (although the team are committed to finding any means to restore a Blancpain watch), prices for restoration start at around 2,500 Swiss francs.

Even when Blancpain makes a new watch today, the tools used to do so are carefully stored away. As a result, unlike many brands that may discontinue support after a few years, Blancpain can guarantee that components needed to restore a watch will always be available, or can at least be reproduced. The selection of tools made for various components is impressive, facilitating the reworking of edges and other such details in the decoration studio. Each tool is carefully crafted, often from wood, to maintain the highest quality. This commitment is an important one, not least for clients who see their Swiss watch as an investment or heirloom.

After a final feast of freshly baked little cakes washed down with Blancpain’s own Blanc de Blanc champagne alongside a closer look at some of the horology house’s latest novelties, it is time to gird our loins for the winding journey over the mountains, away from the Vallée de Joux and back towards Geneva.

A visit to Blancpain’s manufacture buildings in Le Sentier and Le Brassus offered a fascinating insight into the intricate and meticulous world of watchmaking at its absolute finest. The dedication to precision and the combination of traditional craftsmanship with modern technology is evident at every step of the process. Down to the smallest tool, Blancpain prides itself on doing everything in-house. This in-house capability allows for unparalleled control over the quality and design of the tools needed for production.

To end with a little-known fact: the term ‘manufacture’ originates from the Latin term for ‘made by hand’ – and Blancpain’s manufactures, nestled deep in the Swiss countryside, truly do this term justice. Blancpain’s commitment to quality and tradition is evident throughout the manufacture; from the initial design to the final assembly, every step is handled with the utmost care and attention to detail. Paying a visit to the heart of Swiss watchmaking not only highlighted the intricate craftsmanship involved in watchmaking, but also showcased Blancpain’s dedication to preserving and advancing the art of horology for generations to come.