Recently, Dior released five new models expanding its Chiffre Rouge collection. We are going to run through these new additions.

In the middle of last year, Jean Arnaud, who is responsible for Louis Vuitton’s watch division, announced a new era for the maison’s iconic Tambour model. The drum-shaped case has been given a contemporary facelift, and the positioning of the model will focus upon the high-priced luxury watch segment in future. The range has therefore been streamlined, with around 80 percent of entry-level watches being replaced by the new Tambour models. At today’s presentation of new products by Louis Vuitton, however, it is not a new Tambour that is being unveiled, but another model that has separated itself from the Tambour in recent years and is now an independent line: the Voyager. However, Louis Vuitton is not presenting a new movement from its watchmaking workshop La Fabrique du Temps, but rather demonstrating all its skills in the revival and careful cultivation of traditional craftsmanship.

The Voyager was presented as an independent line for the first time in 2016, having previously run under the Tambour (Tambour Voyager). In complete contrast to the Tambour, the Voyager case has a rounded bezel in a slightly ovoid-shaped case. The Voyager Flying Tourbillon from 2016 was also the first Louis Vuitton watch to be awarded the Poinçon de Genève (Geneva Seal). The coveted seal, which is one of the highest standards in the industry, requires a number of strict criteria in terms of finishing, decoration and precision of the movement. In addition, the watch must be assembled and regulated in the canton of Geneva. Only a handful of watch brands are currently entitled to the seal. Since Louis Vuitton’s acquisition of Le Fabrique du Temps under the direction of Michel Navas and Enrico Barbasini in 2011, it has been a clear signal to the world that Louis Vuitton intends to be taken seriously in haute horlogerie.

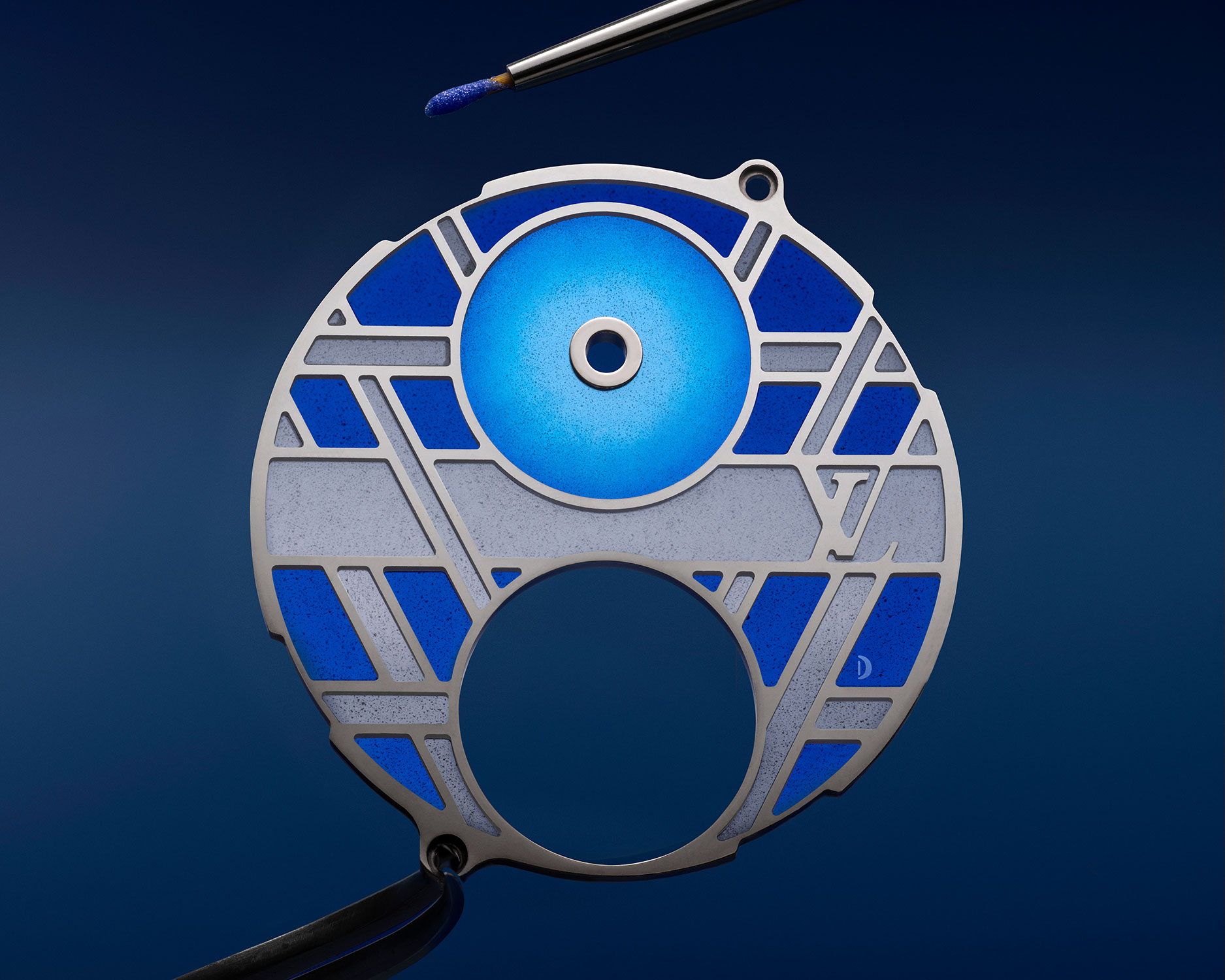

The Voyager Flying Tourbillon ‘Poinçon de Genève’ Plique-à-jour uses the flying tourbillon movement, calibre LV 104, from 2016. It has a unique architecture, as it runs vertically through the case and is mounted on V-shaped bridges in homage to the maison. Introduced last year as an open skeletonised model without a solid dial, this new creation features a beautiful stained-glass window adorning the skeletonised movement, which is somewhat reminiscent of ancient church windows. The technique is called plique-à-jour, and was used as early as the 4th century in Byzantine jewelry and enamel work. The technique also spread rapidly in Europe and was first documented in France in the 14th century. Today, very few artisans in Europe still master this form of enameling. Louis Vuitton tracked down some of them, hired them, and after a few months of research, the first dials were produced in Louis Vuitton’s La Fabrique du Temps atelier.

Together with its master enamellers, Louis Vuitton chose the ‘percé’ technique, which is considered the most sophisticated of the various plique-à-jour methods. Enamel is applied to the sections without any backing. Using traditional ‘capillary action fill’, the enameller applies the paint to each piece with a brush. As the paint is not applied to the back of a dial, but into the open sections, the challenge is that the enameller must work very quickly and precisely and distribute the paint evenly and without air pockets. The V-shaped pieces (here again the nod to Vuitton) are made of white gold.

The greatest difficulty, however, was the production of the central dial for the time display at 12 o’clock. On the one hand, the plique-à-jour enamel had to be applied to a larger area, and on the other, an opening for the hands had to be cut out and centered with absolute precision. Around 100 hours of work went into a single dial. In total, up to six layers of translucent enamel and just as many firing processes are required to achieve the transparency and colour tone, which alternates between ultramarine, azure and blue-grey. On the left-hand side at 9 o’clock, Louis Vuitton has taken the opportunity to prominently display the Poinçon de Genève certification seal. It will no doubt immediately catch the eye of connoisseurs – and these exceptional timepieces from Louis Vuitton are made for precisely this target group.

The hand-wound calibre LV 104 was manufactured entirely in-house at La Fabrique du Temps. It consists of 168 components that take around 120 hours to assemble. The calibre LV 104 offers a power reserve of 80 hours. As with the flying tourbillon, the case is made of 950 platinum and 18-carat white gold, with alternating polished and brushed surfaces. The new Voyager Flying Tourbillon ‘Poinçon de Genève’ Plique-à-jour is worn on a matching navy-blue calfskin strap. Price: 330.000 Euro.