The latest instalment of the epic Roger Dubuis Excalibur Knights Of The Round Table collection brings the twelve knights to an icy blue landscape.

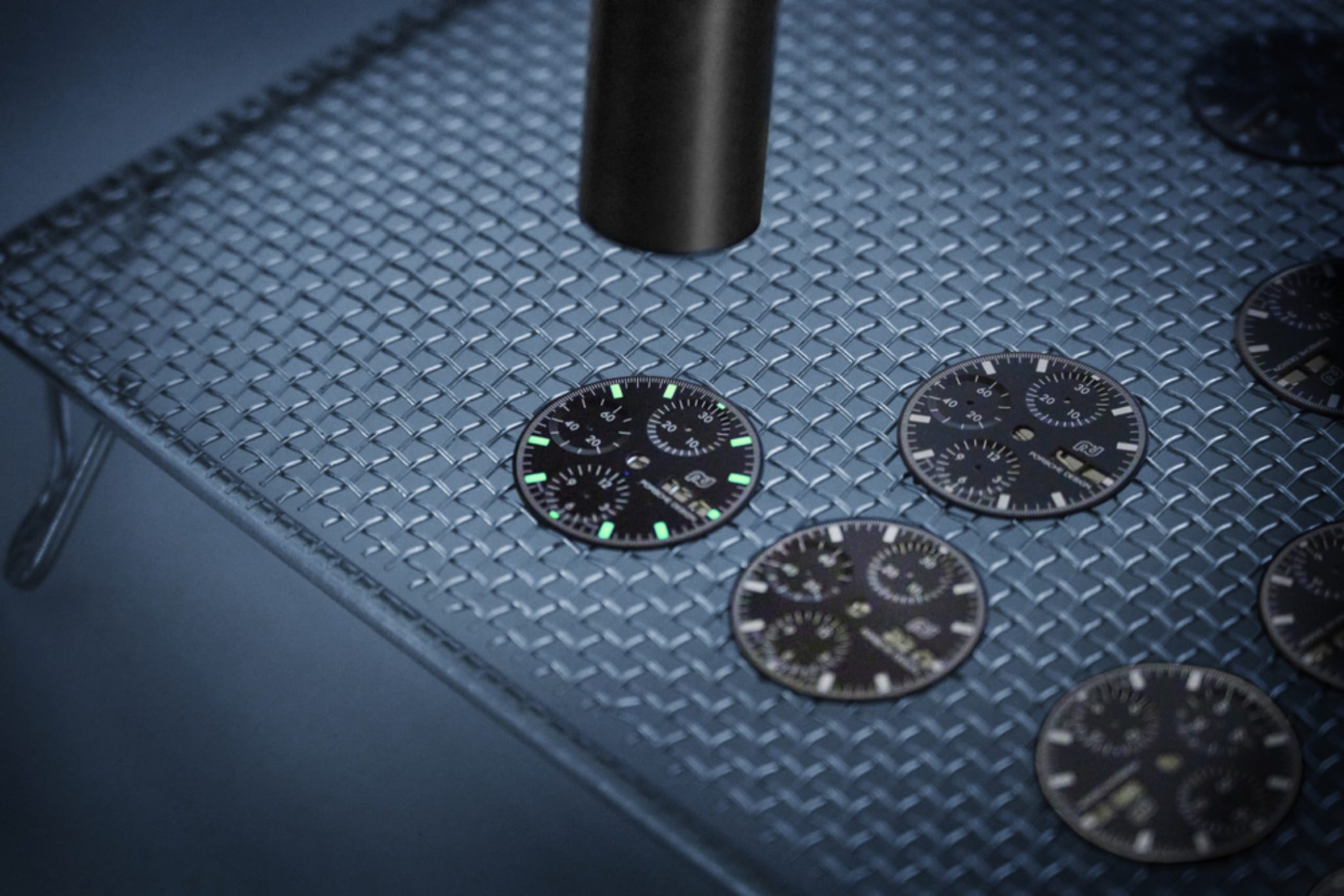

Porsche Design Timepieces AG in Solothurn is revolutionising the Swiss watch industry with its innovative custom-built technology. As the only car manufacturer in the world to operate its own watch manufacture, Porsche combines sequential production with traditional Swiss horological craftsmanship.

Despite iconic watch models in their 51-year history, many collectors and connoisseurs of fine mechanics do not necessarily associate Porsche Design with the term ‘watch manufacturer’. And yet Porsche Design’s Swiss subsidiary, Porsche Design Timepieces AG, is currently developing something that could turn the Swiss watch world upside down and revolutionise it. An exclusive visit to Porsche’s factory in Solothurn raises one particular question: Do we need to rethink the term ‘watch manufacturer’ in the future?

Since 2014, Porsche Design Timepieces AG has been redefining traditional Swiss watchmaking. The Solothurn location was chosen strategically for its position at the heart of the Swiss watch industry.

Strategic advantages of the Solothurn site:

How must company founder Ferdinand Porsche have felt when he walked through his Werk 1 in Stuttgart to inspect the work on the 356, the first series Porsche, in 1950? Back then, they were just a few brick halls. Today, they seem tiny, embedded in the vast corporate area in Stuttgart-Zuffenhausen with over 600,000 square meters.

This question comes to mind when you enter Porsche Design Timepieces AG. The company has rented a few premises in Solothurn in this simple concrete building. It is not a representative company museum, let alone a reception building with which so many well-known Swiss watch manufacturers like to advertise themselves.

Porsche’s Headquarters in Zuffenhausen ©Porsche AG

Rolf Bergmann, a logistics expert with 25 years of experience and a key contributor to the development of the Porsche 996 Turbo, brings invaluable automotive expertise to the world of watchmaking.

Rolf Bergmann, CEO Porsche Timepieces AG (l.) and Gerhard Novak, General Manager Timepieces (r.)

For the first time, he is granting journalists access to his ‘little holy grail’, as he and his colleague Gerhard Novak, General Manager Timepieces, affectionately call the premises. Today is not just about exclusive access but also about exceptional insights into a topic that is revolutionary for Porsche and the entire Swiss watch industry. Therefore, Bergmann and his marketing colleagues have come up with a unique claim that is on point: ‘A sports car on your wrist.’

In 1972, Ferdinand Alexander Porsche created the Chronograph I, the world’s first black wristwatch—a milestone in horological history whose influence endures to this day. But how did a family rooted in motorsport turn its attention to luxury watches?

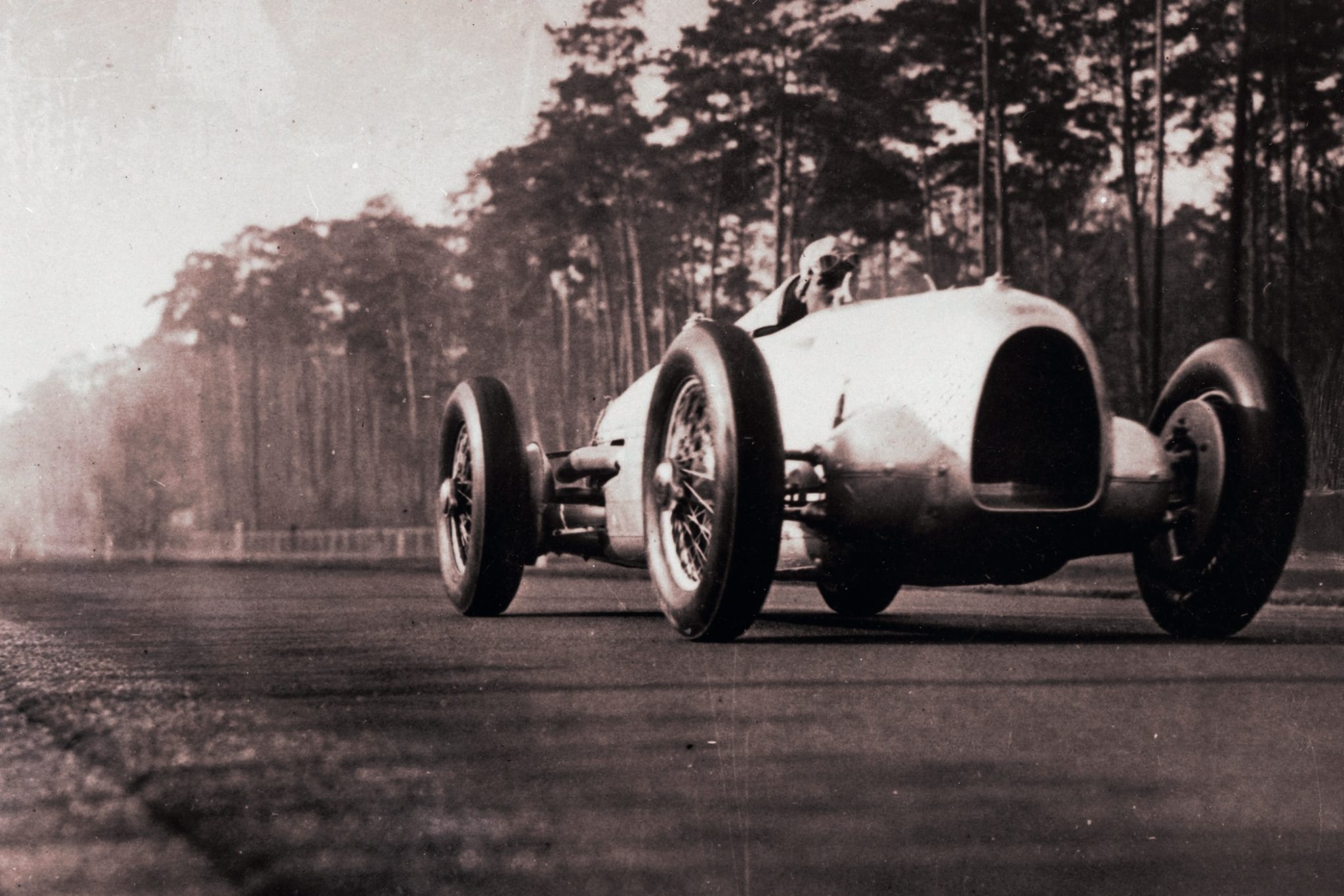

For decades, Porsche meant motor races or at least street racing. Watches? Let the others do it. His grandfather Ferdinand, an enthusiastic and equally gifted engineer, gave the world the Beetle while designing Auto-Union racing cars.

Then there was his father, Ferry, who made his motorsport debut at Le Mans in 1951, just three years after presenting his first sports car under his Bohemian name. With the 356 SL and just 45 hp, French Porsche importer Auguste Veuillet and his compatriot Edmond Mouche immediately won in their class. Five years later, in 1956, the small family business entered the Targa Florio, the most challenging endurance race of its time, on 10 June. Umberto Maglioli’s Porsche 550 Spyder effortlessly outpaced the competition from Maserati and Ferrari in the mountains of Sicily. The lead over the runner-up: 15 minutes. But no trace of watches (yet).

Porsche motorsport milestones:

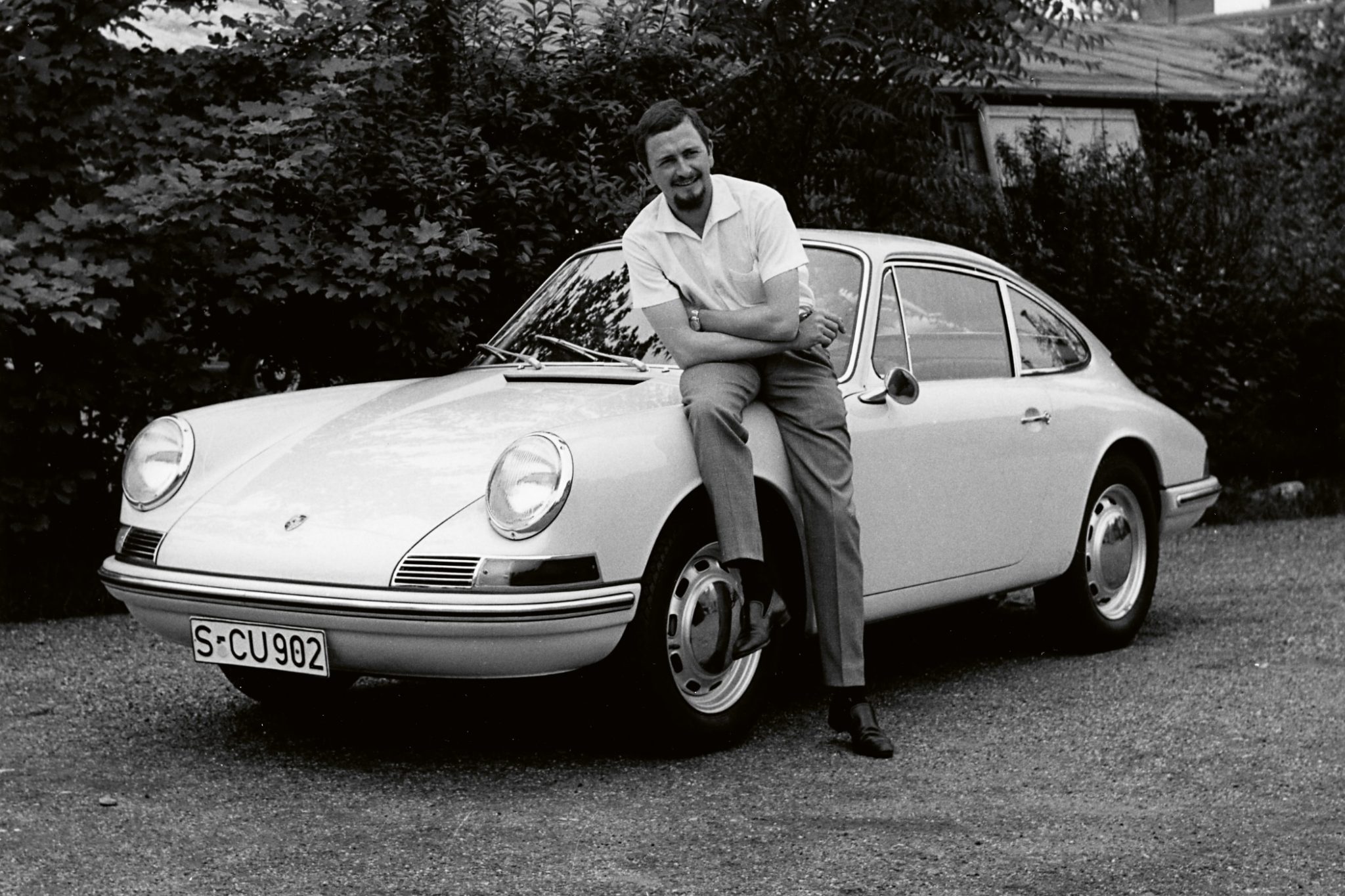

And then there was the creative son, Ferdinand Alexander, who studied at the Ulm School of Design. He created a car design with his team that was meant for eternity in 1963 – the Porsche 911, which was called 901 when presented at the IAA of the same year.

Ferdinand Alexander Porsche mit Porsche 901

What many, including the journalist Reinhard Seiffert from the magazine Auto Motor und Sport, did not foresee at the time: It is the most successful car ever built regarding the racing versions of the vehicle. In the magazine’s eighth issue, Seiffert wrote succinctly, ‘Without question, the new sports car, which will be produced in Zuffenhausen from the end of August, is one of the most interesting cars in the world. It is exclusively intended as a touring vehicle, not for Gran Turismo racing.’ It seems that few motorsport journalists have ever been proven more delightfully wrong. And that, perhaps, is the point. The question remains: how did Porsche evolve from racing cars to luxury watches?

‘F. A.’, as he was called outside the family throughout his life and as everyone here in Solothurn still calls him to this day, first immortalised himself as the designer of the Porsche 911, and then independently: When the members of the Porsche family left the operational business of their own company in 1972 (the conversion of the company’s legal form to a public limited company required this), Ferdinand Alexander Porsche founded his design studio, with which he returned to his childhood home of Austria two years later.

His first project was not a commercial venture, but an extraordinary watch created for long-serving employees of Porsche AG. The initial commission asked Mr Porsche to design a timepiece of which only twenty would be produced each year. With the black Chrono I, F. A. Porsche ultimately created the world’s first black wristwatch.

Why it turned out to be a chronograph goes without saying for motorists. However, Novak explicates what even they might not know, ‘The Porsche family have always liked to surround themselves with good watches and knew their way around the segment very well.’ He discovered an interesting detail in the Porsche archive: ‘Probably since 1950, but certainly since the mid-1950s, all Porsche customers who reached the 100,000-kilometre mark with their car received a solid gold watch with Porsche lettering as a gift from Porsche.’

Due to the vehicles’ high quality, more and more customers archived this mileage. Therefore, frequent drivers were awarded a gold pin since the end of the 1950s. Interestingly, the first Chrono I models began appearing on prominent personalities’ wrists as early as 1974.

Famous Chronograph I wearers:

Since the late 1970s, the Chronograph I enjoyed a second career off the racetrack. Due to its nearly glare-free readability and thus maximum functionality, the timepiece was also used by many armies: NATO, the German Armed Forces, the Swiss Army, but also the Emirates and, of course, the US Air Force, which used the head of a tiger in its logo. Whether air or naval forces, Novak adds, ‘These units have commissioned watches from Porsche Design to equip their units.’

In the 1980s, the Chronograph I conquered the silver screen on Tom Cruise’s wrist in the first Top Gun film. When US director Jerry Bruckheimer began filming Top Gun in 1985, the aim was to provide the actors with authentic equipment. The Top Gun flying squadron was conveniently based in Miramar near Hollywood. Novak knows the story down to the last detail: ‘As the Tigers were wearing the Chrono I, Bruckheimer went to the Porsche Design Store in Beverly Hills and asked for this model. They lent him the Chronograph I that actor Tom Cruise wore in the first part of Top Gun in 1986.’

The timepiece achieved cult status as a result and is now considered a modern watch classic. Throughout five decades, around 50,000 models were produced by various manufacturers: First by Orfina, later by Eterna and today by Porsche Design – as a limited and customisable edition.

With the founding of Porsche Design Timepieces AG in 2014, Porsche AG and its subsidiary Porsche Design in Ludwigsburg set the course for the future. Following its near bankruptcy in the early 1990s, Porsche AG had risen to become one of the most valuable automotive brands in the world – not only by diversifying its model range but, above all, with a unique production principle based on customer wishes: highly customisable and limited-edition sports cars because that is exactly what fans expect from Stuttgart-Zuffenhausen.

The Swabian inventors thought, ‘That’s all well and good’. But what if customers could customise their wristwatch in the same way as their personal sports car? A gimmick? The auction results of rare wristwatches in recent decades tell another story. Not only do they perform better than many shares, but valuable individual pieces are particularly sought after, as Paul Newman’s Daytonas impressively prove (read our article here).

Porsche Design watches are neither Rolex nor Patek Philippe. Not yet. But men like Rolf Bergmann are paving the way for the holistic Porsche experience. At the time, he aimed to match timepieces to an individual’s car 100 per cent. Bergmann remarks, ‘Right from the start, we were aware that the effort involved would be extreme.’ For the Porsche 911 alone, there are 17 standard colours, five wheel types, and over 20 leather finishes in the vehicle configurator.

Bergmann recalls, ‘With the Turbo S Exclusive Series, we offered a limited-edition watch with the car for the first time in 2017 and it was only available when you purchased a car.’ It was such a success – almost half of all car buyers concurrently ordered the watch for 9,950 euros – that the wires between Ludwigsburg, Zuffenhausen and Solothurn were buzzing. Had they just discovered a new business model? They had. The engineers and designers immediately asked: what if every Porsche driver could order their personalised Porsche for their wrist directly from the Car Configurator in the future?

According to Bergmann, ‘We had been working under high pressure and went online with our watch configurator three years ago. Today, every customer who configures a Porsche 911 can then be offered a matching wristwatch that can be customised even further.’ However, he also knows that not every Porsche is automatically a coveted collector’s model.

However, one thing is certain: Porsche Design is writing another piece of watchmaking history with the so-called ‘Porsche Design Custom-built Timepieces’ and opening a new chapter in the manufacture of wristwatches.

The idea of the sports car on the wrist is based on an entirely new development and manufacturing process for wristwatches. Bergmann is happy to explain this in detail. His eyes light up with enthusiasm: ‘To be able to offer a completely customisable wristwatch with countless possible combinations in a series production, we had to heavily intervene in the processes of how watches are manufactured today, right down to how the customer assembles their personal timepiece to match their vehicle.’

The processes that customers digitally trigger through their selection in the Porsche Design Timepieces configurator change all production processes and supply chains and even influence how custom-built watches are constructed and designed by Porsche Design.

The idea of establishing the company’s own watch production facility in Switzerland was born. Nowak remarks, ‘Nowhere is there greater expertise in the production of individual components for watches with our quality standards than in Switzerland. And even there, only in certain regions. Therefore, the Solothurn location was integral to the concept of Porsche Design’s custom-built timepieces.’

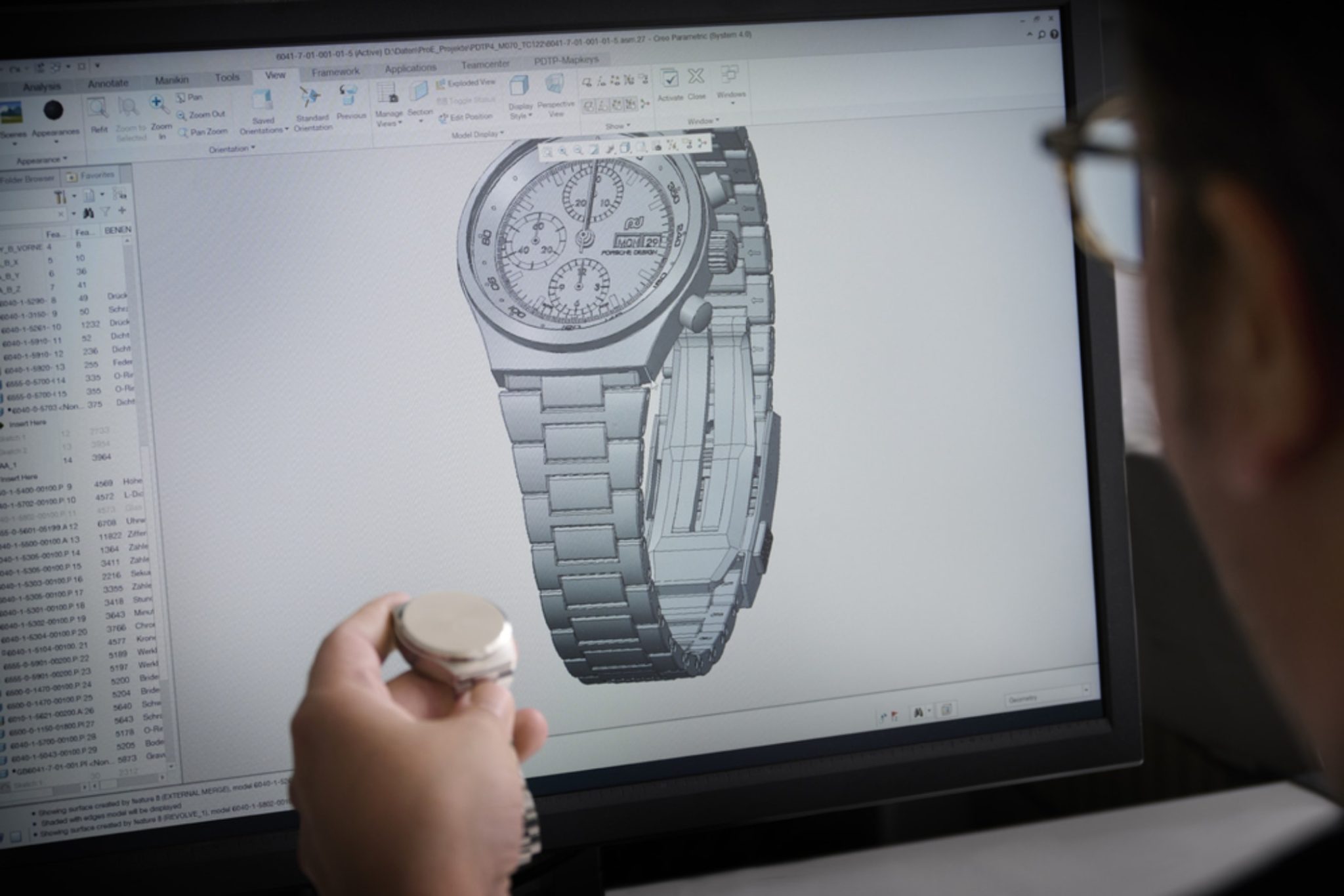

The design and construction process for wristwatches also had to be reorganised, and Studio F. A. Porsche at Zell am See was heavily involved in the concept. Bergmann elucidates, ‘It quickly became clear that we would need new cases or bracelets with completely different details for such a concept, which would allow a high degree of individualisation. These components must be interchangeable without having to develop a new watch each time.’ Therefore, a wide range of variants in small quantities is made possible by the sequential manufacturing of the custom-built chronograph inspired by Porsche’s vehicle construction.

Porsche Design is transferring its proven automotive sequential production process to watch production for the first time. With over 200,000 configuration options per watch, the company is setting new standards in the personalisation of luxury watches.

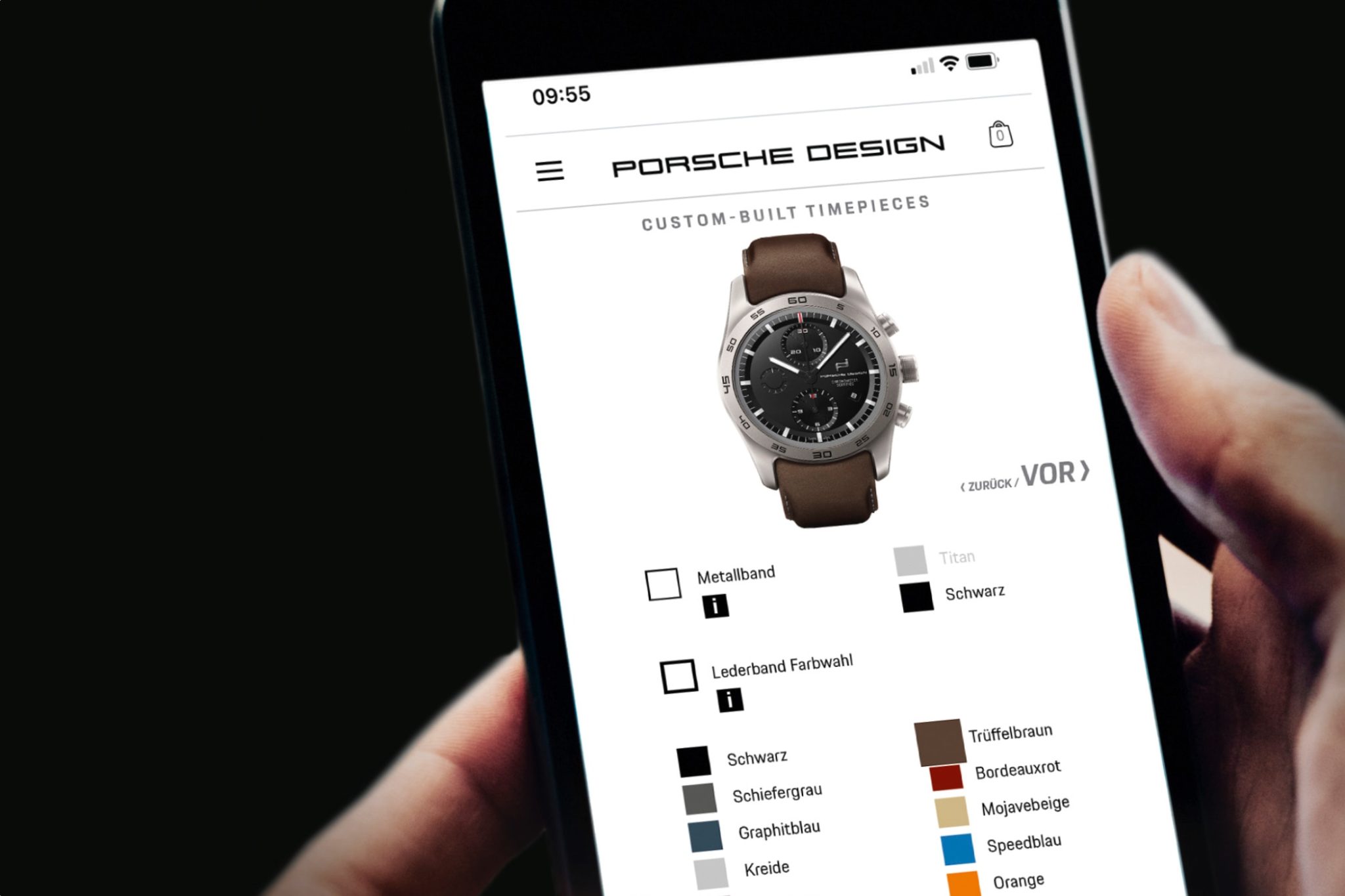

But how does it work? The watch buyer starts with the Porsche Design configurator, which was specially developed and is technically the most complex of its kind for mechanical wristwatches worldwide.

Configurator capabilities:

Even though Bergmann speaks of ‘countless’ design variants, the truth is that they can be counted – or rather calculated. If you consider all the different yarns that would be possible for the watch straps, there would theoretically be over 300 million variants from which customers can choose to assemble a watch.

The Porsche Design Manufacture Calibre 01.100, featuring a 46-hour power reserve, marks a world first by combining COSC chronometer certification with a customisable winding rotor modelled on the design of the Porsche 911 wheel rim.

The customisable wheel rim rotor represents the most technically sophisticated component of the custom-built Timepieces collection. Crafted as a 1:22 scale version of the original rim, adapted to the timepiece’s geometry. The rotors are manufactured with an accuracy of up to five-thousandths of a millimetre.

The Wheel Rim Rotor: automotive engineering in miniature

| Specification | Details |

| Scale to original rim | 1:22 |

| Manufacturing tolerance | ±0.005 mm |

| Porsche crest size | 3.3 x 4.4 mm |

| Available rotor typesAvailable rotor types | 7 variants |

| Colour options | All 163 Porsche colours |

| Material | Titanium/coated |

From the classic Carrera rim, complete with rotor cover and bi-coloured Porsche crest, to the Exclusive Design wheel featuring a golden crest, seven different rotor types are available. The outer edge of the rotor can also be painted in the customer’s preferred vehicle colour – mirroring the finish of their own Porsche wheels.

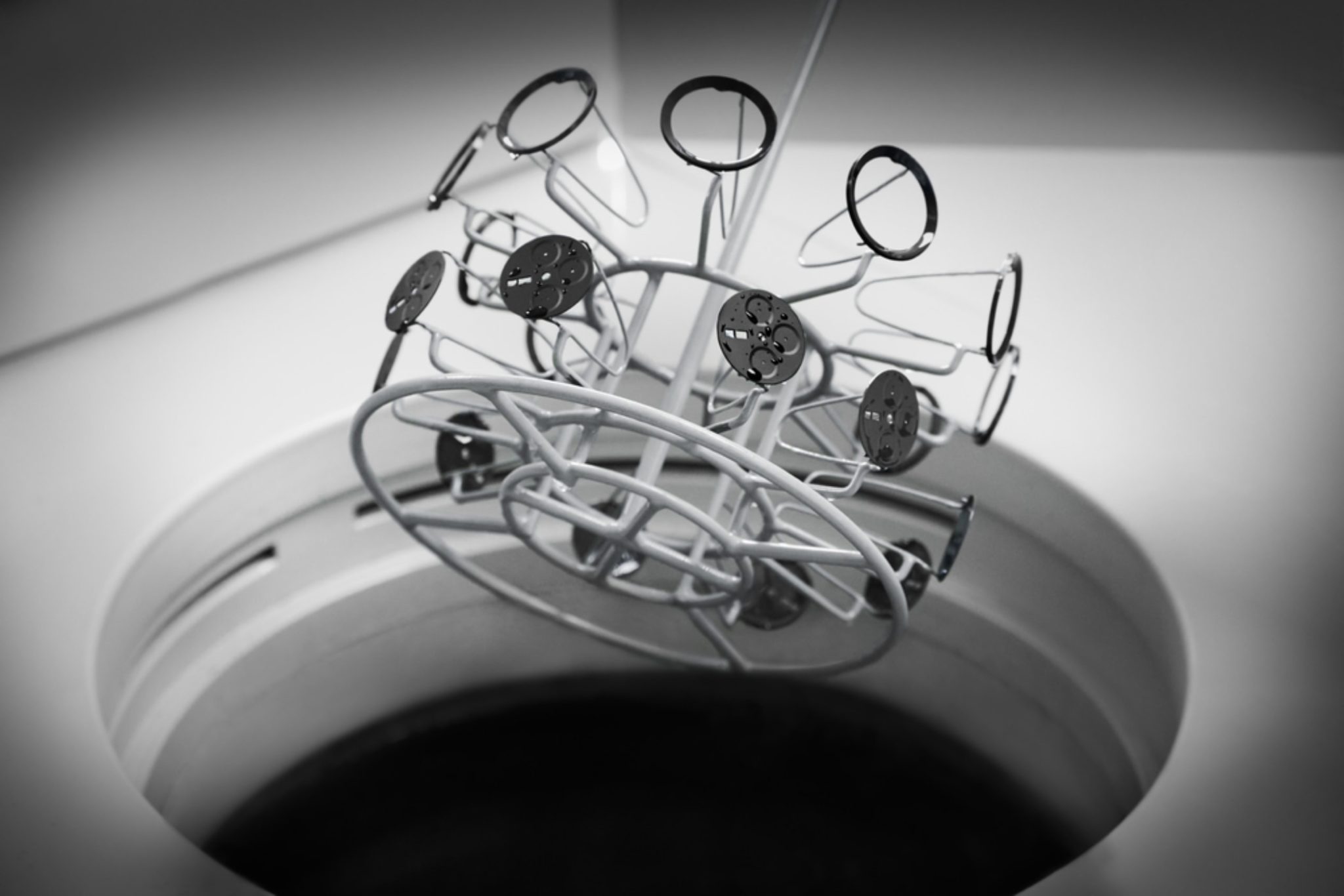

All Porsche Design custom-built Timepieces meet the highest Swiss Made standards, achieving a Swiss value creation depth of over 90 per cent. According to Bergmann, ‘The depth of added value in Switzerland is over 90 percent, well above the legally required 60.’ All Porsche Design movements are also checked for accuracy by the COSC (Central Swiss Testing Center Contrôle Officiel Suisse des chronomètres).

Swiss Made quality features:

At Porsche Design custom-built timepieces, the zero-defect principle applies throughout production. Since each component is made specifically for a single customer order, the watchmakers must rely on absolute precision. Quality control is therefore integrated continuously into every stage of the process — from functionality testing to verifying the exact specifications chosen by the customer. The goal: perfection in every personalised detail.

Porsche Design custom-built Timepieces use only authentic Porsche materials – from the same premium leathers used in the vehicles to perfectly matched paint colours across all 163 Porsche shades.

Personalisation options at a glance:

| Component | Options | Highlights |

| Straps | 900+ variants | Original Porsche leather, titanium |

| Colours | 163 Porsche shades | Historical and current tones |

| Leather | 16 original colours | Identical to vehicle seats |

| Stitching | 16 interior hues | Genuine Porsche thread |

| Hands | 2 variants | ‘Essenz’ or ‘Performance’ |

| Bezels | 2 options | Minute scale or tachymeter |

| Engraving | Individual | Personal laser engraving |

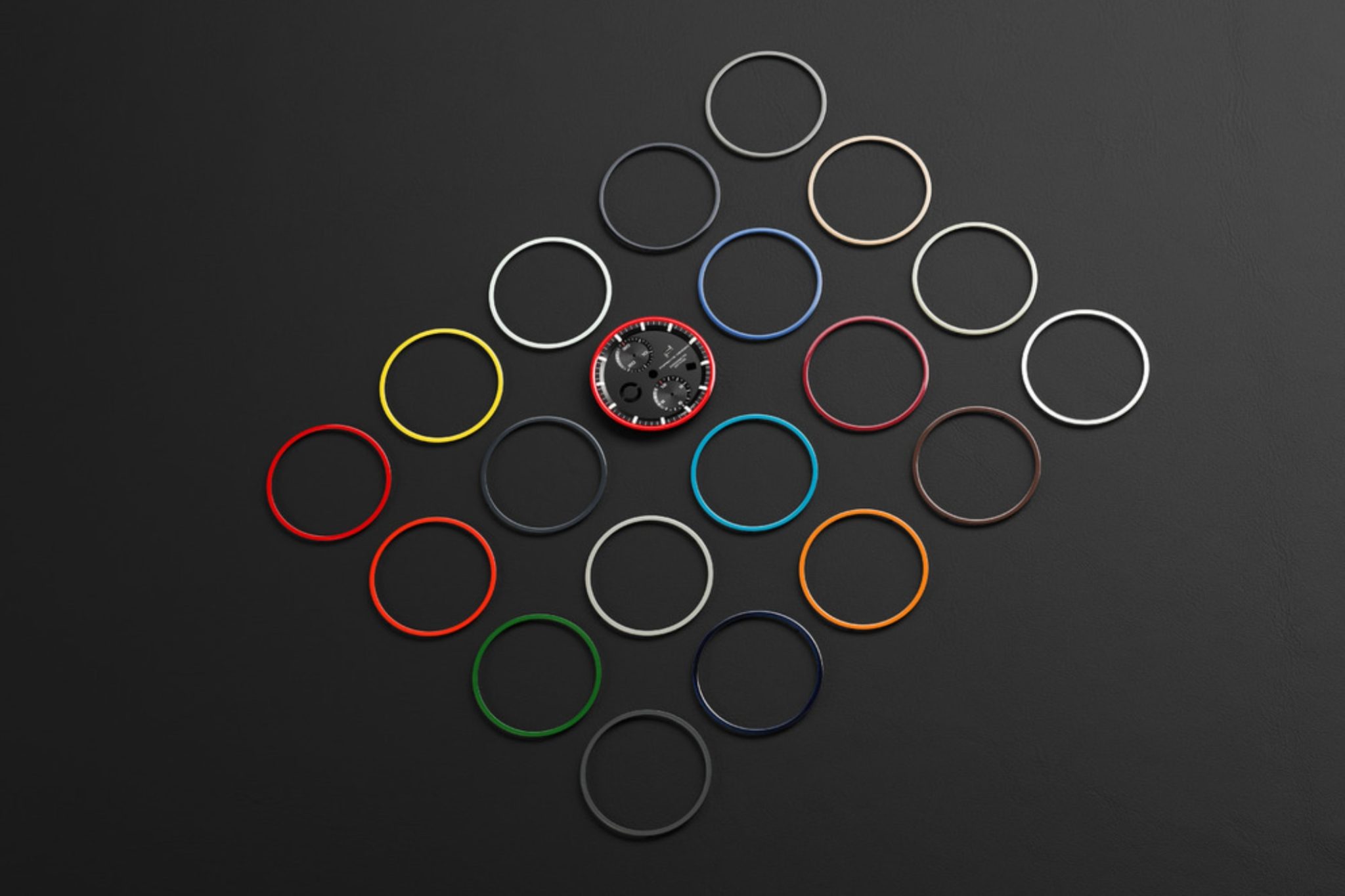

The dials are customisable through inlaid, coloured dial rings with a minute scale developed by F. A. Porsche in the style of classic vehicle speedometers. There are 36 vehicle colours and 21 leather colours to choose from. Customers can even personalise the hands and choose between the ‘Essence’ hand (black rhodium-plated with red tip) and the ‘Performance’ hand (matt white with red tip). Moreover, the customer can pick the bezel in natural titanium or black coated with a classic minute track or as a tachymeter scale for lap time measurement.

The Porsche Design custom-built straps are made from 100 per cent genuine Porsche sports car leather, available in all 16 original Porsche 911 interior colours, and are complemented by hypoallergenic titanium bracelets featuring a titanium carbide coating.

Detailed strap specifications:

| Strap Type | Material | Variants | Highlights |

| Leather straps | 100% Porsche sports car leather | 16 original colours | Identical to vehicle upholstery |

| Metal bracelets | Hypoallergenic titanium | 2 surface finishes | Glass bead-blasted natural titanium or black titanium carbide coating |

| Stitching | Genuine Porsche thread | 16 interior colours | Finer thread for refined aesthetics |

| Clasps | 2 variants | Butterfly/fine adjustment | Seven-step micro-adjustment |

| Sizes | 3 options | Medium/Large/XL | No stock production; made to order |

The extraordinary level of craftsmanship is perhaps most evident in the bracelets. They are available in leather or titanium, and in three sizes. Each titanium bracelet uses only hypoallergenic materials, with every link individually screwed for maximum durability and comfort.

All leather bracelets consist entirely of the same leather used for the Porsche sports car in the 16 original leather colours of the Porsche 911. Porsche Design even uses the original thread in the colours of the Porsche interior for the decorative stitching.

Customer preferences for watch straps:

Porsche Design uses all 163 original Porsche colours, including 127 historic classics such as Gulf Blue, Ruby Star and Mint Green. Each paint must be specially reformulated for application to miniature watch parts.

Rolf Bergmann’s team needs the exact colour for all coloured components long before watch production begins: For more than two years, he has known which colours the Porsche 911 of the 992.2 series, the upcoming facelift, will be available so that he can let his suppliers develop the varnishes.

Paint development process:

Historic Porsche colours (selection):

Since 2022, the design palette has been expanded by an additional 127 historic and iconic Porsche colours. Customers can now also select coloured rings surrounding the dial, inspired by these legendary vehicle paints. The palette includes Gulf Blue, Ruby Star and Mint Green – celebrated hues that have achieved cult status among Porsche enthusiasts.

On request, every Porsche Design Chronograph custom-built can be fitted with a personal laser engraving, applied directly at the Solothurn manufacture. Even the presentation box can be personalised with a matching vehicle graphic.

For this, customers can choose from model designations identical to those on the rear of their own Porsche, or opt for a graphic element such as the silhouette (‘Flyline’) of the current 911 Carrera. According to our research, no other watch manufacturer offers this level of personalisation for series-produced watches.

Engraving options:

The modular design of the custom-built timepieces also transforms the after-sales process. Replacement parts are integrated into ongoing production sequences with virtually no additional effort.

For the first time, Porsche has successfully transferred the principle of sequential production – long perfected in automotive manufacturing – into the world of fine watchmaking. Each timepiece is assembled to order, guided by a detailed picking list, just like a Porsche on the assembly line.

The term sequential production originates in the automotive industry, where Porsche has refined it to perfection. In essence, incoming orders from Porsche Centres are digitally sorted into a virtual sequence, which is then locked for production. If a customer wishes to make changes after confirming their order, these can be accommodated until roughly seven working days before component manufacturing begins – handled directly via their Porsche Centre.

Sequential production in the watch manufacture process:

The process is almost identical to automobile production in Zuffenhausen. Each watch has a specific order form with a picture of the watch and a so-called picking list from which one of the watchmakers on site gathers all the components. The watchmaker has a small cart with a picking box with small compartments for all the components he must collect from the logistics warehouse. He ‘picks’ them, as they say in the car industry: the right flywheel here, the right hands there, then the screws, the movement, the case, the dial, the coloured rings in car colours, the bracelets, and the sapphire crystals. The watchmakers rotate from station to station. Experts call this polyvalent. One day, the employee carries out the quality check, and the next, they assemble the customers’ watches.

Once the watch to go with the car has been ordered, further sales issues can be easily handled. Bergmann comments, ‘Customers have been able to transfer the processes from the cars to the watches in no time. Just recently, we received an enquiry along the lines of: my Porsche is performing great. Can you order me the following matching watch for Christmas? Then the customer just sends us the code.’ It is then converted into a production order in Ludwigsburg. After receiving the order, Timepieces AG obtains this code as a production code, also known as a TP code, digitally and in print for security reasons.

The Porsche Design custom-built Timepieces concept also represents a major shift in after-sales and maintenance operations, since replacement parts now require a completely new logistical approach. Bergmann says, ‘Not only do we have to continually add new types of varnish or leather from the vehicles to the range, but we also have to keep available colours and tanned leather spares for service purposes.’

After-sales advantages:

The complexity of the Porsche Design colour palette and the use of automotive terminology make these timepieces impossible to sell through conventional jewellers. ‘The big advantage is how we approach customers, which works differently for traditional jewellers,’ says Gerhard Novak. ‘The jeweller could never sell it because how would they know what colour the customer wants? At Porsche, red isn’t just red: it is carmine red or Indian red. These are things that Porsche drivers know, but probably nobody outside the Porsche community does.’

Despite the complexity and craftsmanship involved in individual production, Porsche Design Timepieces AG must, like every Porsche subsidiary, contribute to the Group’s targeted 20 per cent return on sales. This is made possible through early integration into Porsche’s automotive design processes – ensuring both economic efficiency and uncompromising premium quality.

Economic factors:

The manufacturing costs of each component, such as a winding rotor in the vehicle colour, are crucial for Rolf Bergmann’s calculation: ‘In order to offer something like this, you have to be involved in the design processes long before the series production of an automobile.’

With around 5,000 watches produced annually, Porsche Design is only at the beginning of its journey. Given that Porsche manufactures over 300,000 vehicles per year and has plans for international expansion, the business model holds enormous growth potential.

Market details and future outlooks:

| Market Range | Current Status | Potential |

| Annual Production | 5,000 watches | Scalable |

| Largest Market | USA (35% market share) | Further international expansion |

| Porsche 911 Share | 15% of all Porsche models | Extension to other model ranges |

| Special Editions | 50% watch order rate (GT3, GT2, RS Spyder) | Strong collector and sales performance |

| Available Countries | 6 markets | Expansion planned to Italy, Japan, and Asia |

Although anyone can technically purchase a Porsche Design custom-built Timepiece, these watches are offered exclusively in connection with the Porsche 911 – a model line that currently represents only about 15 per cent of total global Porsche production.

For limited Porsche special models such as the GT3, GT2, or the recently introduced 718 RS Spyder (read our article here), up to 50 per cent of vehicle buyers also order the matching custom-built watch. This strong correlation highlights the exceptional collector appeal and investment potential of these timepieces, which often sell out in record time.

Special edition performance indicators:

Novak summarises, ‘For our limited-edition vehicles, up to 50 per cent of customers in recent years have also purchased the matching watch.’ In other words: as long as Porsche continues to grow, Porsche Design Timepieces will grow alongside it.

Porsche Design is strategically positioning itself within the rapidly expanding collector’s market for luxury watches. With limited editions tied to exclusive Porsche vehicle models and a unique automotive connection, the brand is opening entirely new horizons for collectors and investors alike.

If you compare these statements with the strategies of today’s cult brands such as Rolex or Patek-Philippe, connoisseurs will realise that if Porsche proceeds with this path, a major collector’s brand could emerge – provided that Porsche meets your taste.

Collector market factors:

Currently, Porsche Design custom-built Timepieces are available in just six countries. Planned expansion into Italy, Japan, and other Asian markets could multiply production significantly – particularly in watch-savvy regions with a strong Porsche presence.

Current markets (since 2020–2022):

Planned expansion beyond 2024:

Porsche Design Timepieces AG demonstrates that innovation and tradition can coexist harmoniously. With its revolutionary custom-built technology, the seamless fusion of automotive engineering and horology, and the highest Swiss Made standards, the company is setting new benchmarks for the entire watch industry.

For Ferdinand Alexander Porsche, creator of the Porsche 911 and father of all Porsche Design watches, the idea of uniting car and watch production would have been entirely logical. After all, the concept behind the black Chronograph I was itself inspired by the black dashboard of Porsche sports cars.

Bergmann recalls, ‘Ferdinand Alexander Porsche created the first black wrist chronograph in 1972 with great design consistency. Introducing sequential manufacturing to wristwatch manufacturing initially requires a lot of discipline. But once the process has been learned, customers benefit disproportionately from it. They receive a very personal timepiece with the usual Porsche quality.’

Future Outlook:

Key Takeaways: