The Porsche Design Custom-Built Timepieces Globetimer offers a GMT function and can be personalised to own preferences.

Shortly before his untimely death, pop art icon Andy Warhol created a painting of three timepieces with a rectangle case and a bracelet with horizontal lines on a 111.8 x 111.8 cm canvas. Their colourful outlines diagonally stretch across yellow, mint, black, pink and red areas. The title of the artwork from 1987: Anatom (Rado Watches). Was it a coincidence that he chose the Swiss watch manufacture’s model as a motif? Certainly not. In celebration of its 70th anniversary, Rado had commissioned the painting – but that was not the only reason. The brand was launching the DiaStar Anatom, first released in 1983, on the American market. It embodied the brand’s pioneering technological spirit and its success was to cause such ripples that it left a lasting impact on the brand and the industry. Just last year, this significant model was reissued for its 40th anniversary. Let us take a closer look at why the Anatom was a sensible conclusion in Rado’s product development, what its unique features are, and how it honours Rado’s ‘Master of Materials’ title.

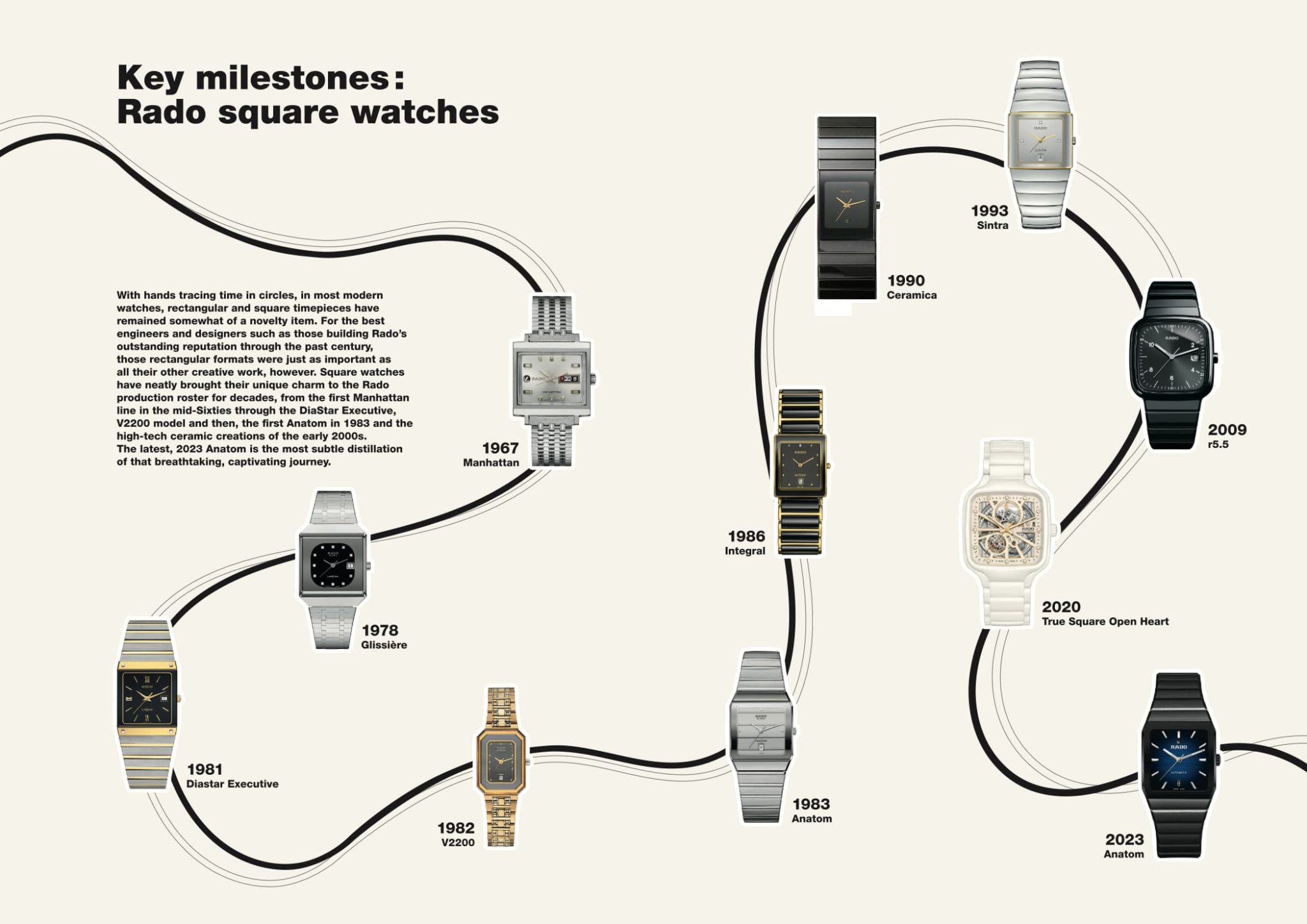

To understand a model and its influences, it is always worth taking a look at the brand’s history first. In 1917, the brothers Fritz, Ernst, and Werner Schlup founded a watchmaking workshop for hand-wound mechanical watches named ‘Schlup and Co’ in Lengau, Switzerland. A few years later, in 1928, they registered the brand name under which the company’s products are known today. Since 1957, it marks all of its timepieces: Rado (Esperanto for ‘wheel’).

The Rado Manhattan from 1967

In the 1930s, Rado was already producing watches with a rectangular, almost square shape. Yet, it was not until the 1960s that Rado started releasing various models with a rectangle or square case whose design should become one of the Swiss watch manufacture’s trademarks. For example, the Manhattan from 1967 had a big square steel case that was waterproof thanks to a patented sealing system. It was equipped with a silver-coloured dial and a date and day of the week display at 3 o’ clock. The case of the Glissière from 1978 was also square in shape. A sapphire crystal, which was attached to the case by two hardmetal rods in a dovetail arrangement at 6 and 12 o’clock, protected the black square dial with its date display at 3 o’clock. The way the sapphire crystal was attached to the case and the delicate steel bracelet, whose links appeared to gradually become shorter, both pointed in the direction of the future Anatom.

The sapphire crystal of the Rado Glissière from 1978 was fixed in a dovetail arrangement using two carbide rods.

In terms of time and aesthetics, the DiaStar Executive from 1981 is even more closely related to the Anatom. This timepiece consisted of a square steel case with gold accents and a black dial with alternating Roman and baton indices, and a date display. Not only did the case’s shape resemble that of the Anatom, but also the bracelet. As with the Glissière, the bracelet links leading away from the gold-coloured lugs attached with four screws became slightly slimmer. However, the bracelet was not as delicate as the Glissière’s and the bicolour bracelet links created a striped pattern through their linear, horizontal arrangement. The DiaStar Executive thus gave a foretaste of the Anatom’s aesthetic, which was released two years later.

DiaStar Executive, 1981

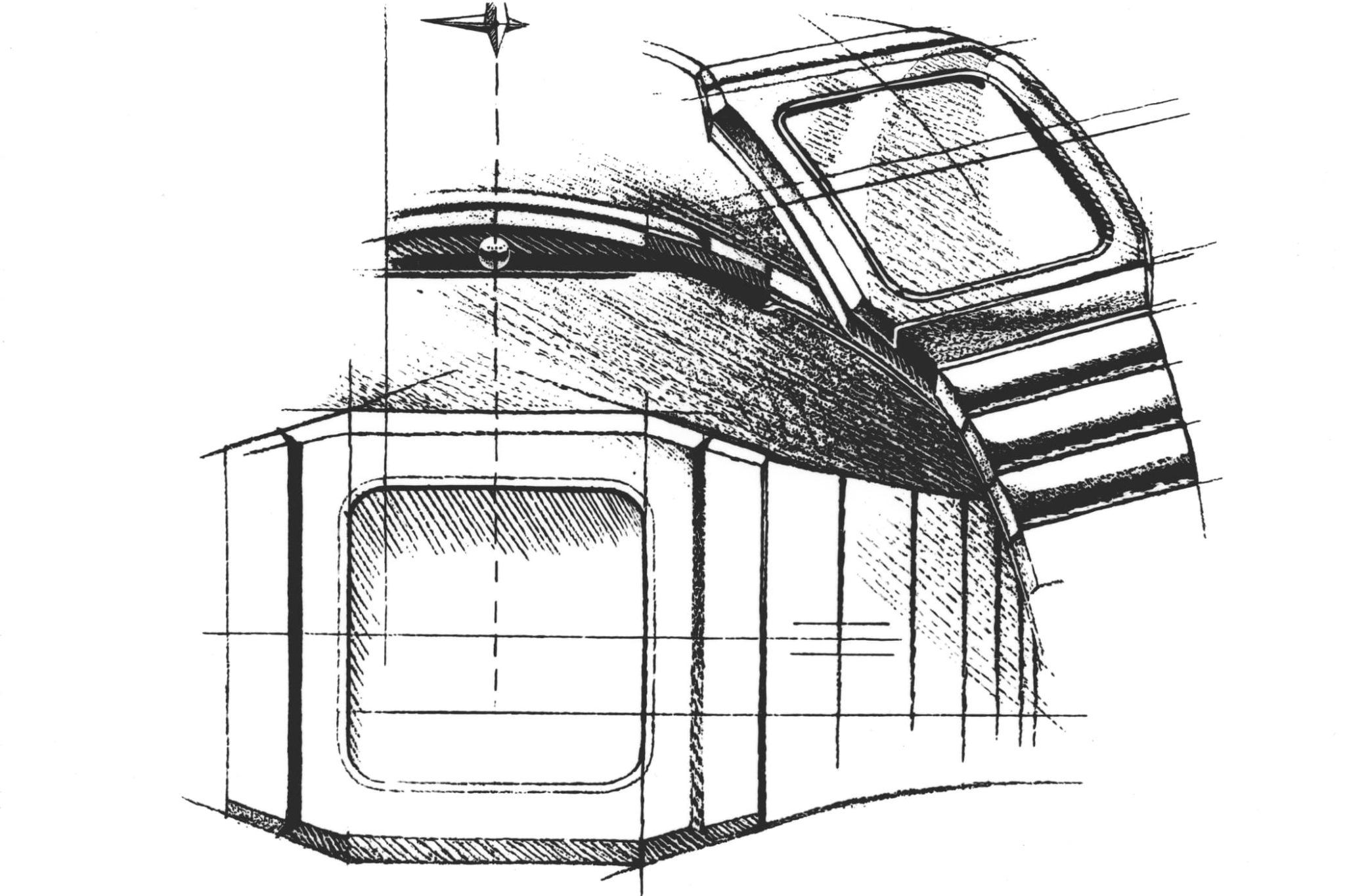

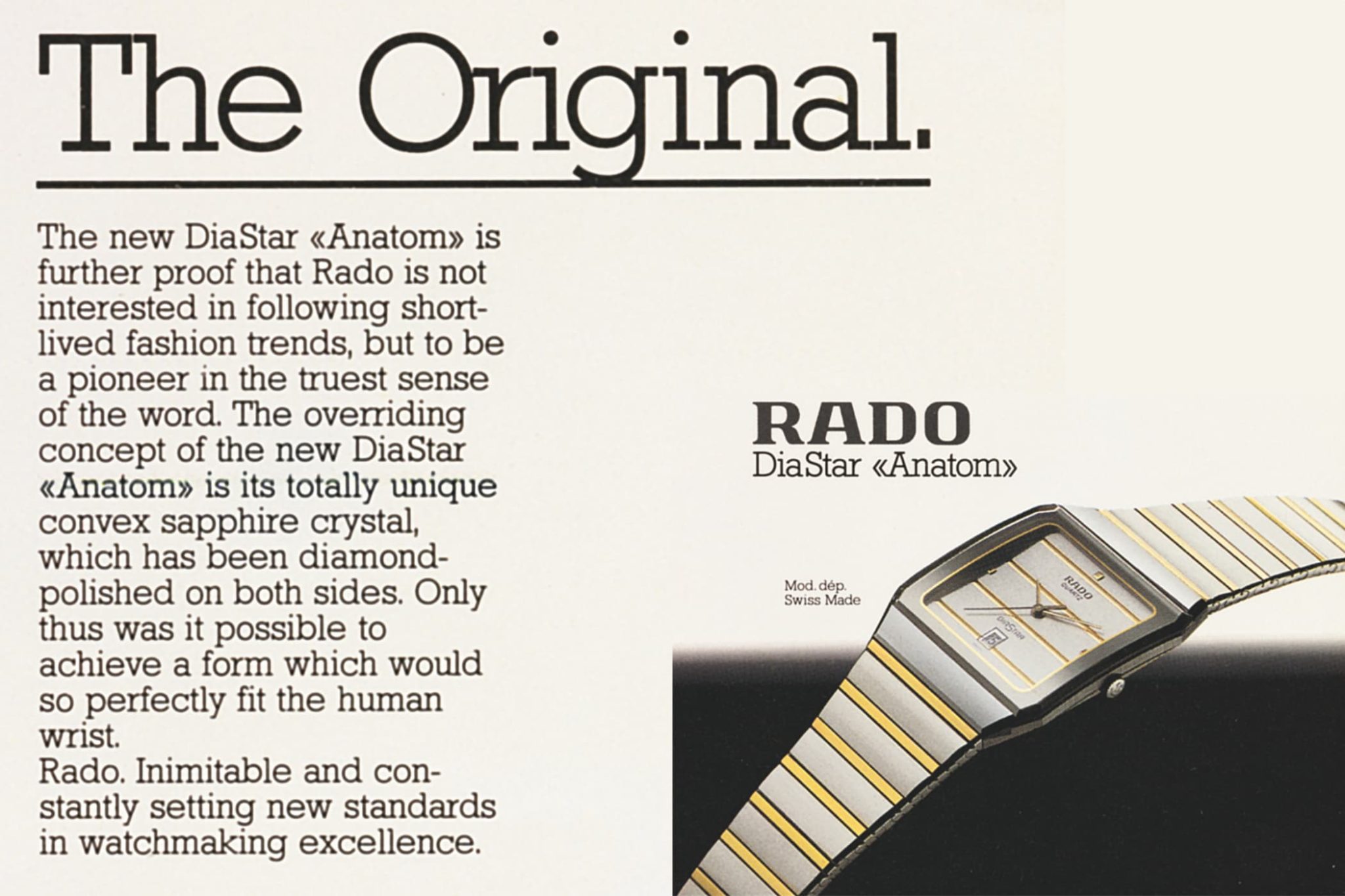

1983 saw the birth of the Rado Anatom. With this timepiece, the Swiss watchmaker took its previous fondness for rectangle shapes and technological advances to the next level. Even the name already suggests it: Anatom is made up of ‘atomic’, alluding to its futuristic design, and ‘anatomical’. The latter attribution points at Rado’s ambition to create a timepiece that, thanks to its convex shape and cylindrical sapphire crystal, would almost ‘anatomically‘ mould itself to the wrist and thus offer a high level of comfort when being worn.

A sketch of the Anatom, circa 1986

As previously mentioned, the new wristwatch shows some parallels to the DiaStar Executive in terms of its appearance. But there is more – initially, they even had a part of their names in common. As the DiaStar models were already well known and had a high recognition value, the Anatom was prefixed with DiaStar to facilitate its gradual introduction. But thanks to its unique design, the Anatom quickly made a name for itself. What exactly did it look like and what technological Rado milestones did it incorporate?

Amongst the trendiest watches of the 1980s were variants in steel, bicolour, and bold colours. Unlike particularly colourful models like Tag Heuer’s Formula 1, the DiaStar Anatom impressed with its puristic aesthetics. Apart from the model and brand name in black lettering and the date display, the entire timepiece appears to be made of steel. If you look closely, however, only the Anatom’s bracelet was actually made of steel. Like the iconic DiaStar, the 28 mm case consisted of hardmetal and had a more delicate appearance compared to its contemporaries.

In 1962, Rado launched the DiaStar as the first scratch-proof model in watchmaking history. Due to its aesthetic longevity, it became a trademark for the brand and set the foundation for its use of high-tech and hard materials. Its special feature: the combination of sapphire crystal and an oval-looking case made of hardmetal, a composite consisting of tungsten carbide, a ceramic, and a metal binder. Initially, the material was developed for tool production in the 1920s but Rado started exploring its features for its own purposes, successfully using it for its watches. During the moulding process, a granulated mixture of tungsten carbide powder, metal binder, and plastic is brought into the right shape. Sintered under vacuum and above the binder’s melting point, the now liquefied material reaches its final density and hardness. Thereby, it shrinks. However, this difference in size is taken into account in advance so that the material is the right size at the end of the process. Finally, the surfaces are mechanically processed and polished using diamond tools and discs to achieve a high-gloss finish. This high-gloss effect can also be found on the rectangular case of the Anatom, which is complemented by a centrepiece and a crown with a steel anchor symbol.

The first Rado Anatom

The shiny case gave the watch a varied look despite its monochrome appearance and the metallised sapphire crystal provided the dial with a wonderful frame. Moreover, the case subtly set itself off from the steel bracelet, whose wider links appeared somewhat rougher in texture. As with the DiaStar Executive, the bracelet’s steel links formed varying narrow and wide horizontal stripes. The links following the ones adjacent to the case became shorter. In contrast to the Executive, the silver-coloured dial also featured horizontal stripes to match the bracelet. As a result, the bracelet and the case appeared to form a continuous unit. The subtle, point-shaped steel indices at 12, 3, and 9 o’clock and the steel hours, minutes, and seconds hands further supported this effect. Meanwhile, a date display replaced the index at 6 o’clock. Viewed as a whole, the smooth transition of colour and structure from case to bracelet contributed to the DiaStar Anatom’s ergonomic appearance. However, another anatomical innovation was not visible at first glance.

While hardmetal was a technological achievement from the past, a new type of three-dimensionally shaped sapphire crystal was used for the DiaStar Anatom. Here, the sapphire crystal presented itself in a cylindrical, i.e. domed, shape and was essential to the overall design of the watch. With a hardness of 2,000 Vickers and inspired by the durability of real sapphires, sapphire crystal is one of the hardest materials in the world. Its structure is identical to that of natural sapphires and harder than other materials used by Rado, such as hardmetal, high-tech ceramics and Ceramos. What’s more, the material is highly transparent, which is why it requires a great deal of knowledge and skill to create and process this material.

Rado was among the first manufactures to use sapphire crystal for its timepieces in larger quantities and in various designs, including smoked tints, colours, facets, and anti-reflective coatings. To complement the case and enable an optimal anatomical fit on the wrist, the sapphire crystal for the Anatom had to be convex, which posed a challenge.

An explanation of the production of sapphire crystal at Rado in Rado – High-tech materials, 1997

It takes more than 60 steps to create an anatomically shaped, domed, scratch-proof sapphire crystal using the Verneuil method and ultra-pure aluminium oxide powder as a basis. At 2,050°C, it crystallises with oxygen and hydrogen in a Verneuil furnace and forms a sapphire block (known as a ‘boule’). During this process, the sapphire block grows by 20 cm every 8 hours and is annealed at very high temperatures for several days. Thereby, residual strains in the crystal structure are released. As soon as the boule is removed from the furnace, it is cut into slices using a diamond cutter. These blanks are then graduated with diamond tools, cut into shape, faceted and polished. For the Anatom, the synthetic material is bevelled and polished from both sides. Handling its inside poses the greatest challenge, as the workpieces are bonded to cylindrical tools before bevelling.

To match the colour scheme of the timepiece, the sapphire crystal was metallised in silver colour. The metallisation process is also extensive and requires 40 additional steps. In a vacuum chamber in a dust-free laboratory, gold or – in this case – chromium vaporises on the sapphire crystal’s underside to metallise it. Later versions were also metallised with other elements. For the Anatom, the decorative pattern that echoes the optical horizontal lines of the metal bracelet and the anatomical shape (through a frame) was traced in a photolithographic process. Last but not least, two protective hardmetal arranged in a dovetail structure at 6 and 12 o’clock were used to attach the sapphire crystal to the case – similar to the Glissière from 1978.

The Rado Anatom therefore impresses its followers with its unique combination of past and recent technological achievements and showcases a consistent further development of the rectangular design. It demonstrates that innovation in watchmaking can be achieved by more than just a complicated movement. The production of materials can be just as ground-breaking and sophisticated, as the manufacturing processes for hardmetal and (convex) sapphire crystal show. When the Rado Anatom was born in 1983, it was its design rather than its quartz Rado calibre 03.152.102 that made it stand out.

Since its launch on the market in 1983, various designs of the Anatom have been released. A product book from 1984 shows that there were gold- and silver-coloured editions. They were available in two different sizes for both men and women. In the mid-1980s, there was also a bicolour edition with wide silver-coloured links and narrow, gold-coloured horizontal stripes, which was very fashionable at the time. Furthermore, there were versions with a hardmetal bracelet coated with black DLC or made of genuine gold.

Pages in a catalogue from 1984 show the Rado Anatom in two sizes and colours

In 1990, Rado launched a bicoloured Jubilé version of the Anatom. Gold-coloured hour, minute and second hands and diamond hour indices at 12, 3, 6 and 9 o’clock shine on the black dial. The date display is located at 6 o’clock. After the quartz crisis had finally subsided, the Anatom first appeared as an automatic model between 1996 and 1997 and enjoyed great popularity in the collection. A new edition of the Anatom, which was launched at the end of last year with four models, now aims to build on this popularity. Like the original, the new timepieces symbolise the developments in Rado’s history – this time from 1983 onwards – and show the influence that the Anatom has had on other models in recent decades.

A diamond-set Jubilé edition of the Anatom, 1990

2023 marked a very special year for the Anatom, as Rado proudly looked back on its 40th anniversary and honoured the influential model with four new editions. While the references to the original are clearly recognisable, the new models move with the times in terms of material and colour. Since the 1980s, Rado has further expanded its range of materials and developed new production techniques. The fact that these are reflected in the new models is in keeping with the spirit of the original Anatom, which was already a symbol of the Swiss manufacturer’s technological success at the time of its creation. Moreover, the new Anatom Automatic models continue the trend of reviving watches from the 1980s, such as the Rolex Datejust Two-Tone. The new collection consists of three standard models with dials in red, green, or blue. There is also a limited edition of 40 pieces, which is already sold out.

Three new Anatom models with colour gradient

Instead of a hardmetal case, the new models are housed in high-tech ceramic with a smooth surface. Compared to the original, the 32.5 x 46.3 mm cases are larger and less delicate. However, as we noticed ourselves when wearing the new models, the larger diameter has no negative impact on the wearing experience. The timepieces fit surprisingly well thanks to the slight curvature and do not appear too large – even on smaller wrists.

Since the launch of the Integral, Rado has been working with high-tech ceramic cases. They are scratch-resistant, lightweight and have a smooth surface. With the black ceramic bracelet links of the Integral, Rado introduced high-tech ceramic to its range of materials in 1986. Four years later, Rado intensified its use of high-tech ceramic and launched the Ceramica in 1990. Not only were its bracelet links made of black ceramic, but also its case and crown.

Rados first timepieces with high-tech ceramic: the Integral from 1986 (left) and the Ceramica from 1990 (right)

As ceramic timepieces were previously only available in black, Rado launched the White Coupole in 1992. It was the first wristwatch in Rado’s repertoire to be made of white high-tech ceramic. In the following years, Rado continuously expanded the colour palette for its ceramic wristwatches by adding pigments – around 20 colours are possible today. Rado also experimented with high-tech ceramic combinations with other materials. The Sintra from 1993, for example, was a fusion of high-tech ceramic and metal, a combination that would later be called Ceramos. Shortly before the start of the new millennium, in 1998, Rado proved that ceramic can shine like metal with the launch of the Plasma Metallic Grey Ceramica. The metal-like look of this plasma high-tech ceramic is archived through a plasma treatment. The treatment occurs in a vacuum vessel where the gases are activated at extremely high temperatures – four times higher than on the surface of the sun. For both the Ceramica and the Sintra, Rado has been honoured for its technological innovations in design competitions. From the 2000s onwards, ceramic models have became particularly important and are closely associated with Rado as a brand. The manufacturing process is similar to that of hardmetal.

All four recently released models consist of a case, a crown, and a bezel made of high-tech ceramic. Although the manufacturing process is the same, the models differ in terms of their structure. While the three standard models feature a matt black ceramic, the ceramic surface of the limited edition is polished. The high-tech ceramic (1,250 Vickers) has a smooth surface and consists of a mixture of zirconium oxide powder and inorganic pigments. They are high-purity and finely calibrated so that they consolidate, creating the high-tech ceramic when fired.

Rado has developed a new process to create its high-tech ceramic timepieces using a plastic carrier to mix with the mineral powders. This allows the material combination to be injected into precision moulds at a pressure of around 1,000 bar. After the material has cooled down, it is removed from its mould. Then, the carrier material is dissolved using chemical solvents according to a standard procedure. The material is then sintered at 1,450 °C in a challenging process. As the particles contract, it shrinks by approximately 23 percent to reach full density. Again, diamond tools are used for further processing.

The limited-edition Rado Anatom Automatic Jubilé, released in 2023

The Anatom models, which are water-resistant to a depth of 50 metres, are complemented by a centrepiece made of sandblasted stainless steel with a black PVD coating. Lugs made of horizontal satin-finished stainless steel and stainless steel pushers complete the case of the three regular models. For the limited edition, the stainless steel is polished to match the case.

The dial and the open stainless steel caseback are covered by a rimless, cylindrical, anti-reflective sapphire crystal. All Anatom Automatic models bear cylindrical, metallised black sapphire crystal with facetted side edges on the front. For better legibility, its inner side has an anti-reflective coating. A transparent sapphire crystal covers the caseback, revealing the automatic movement. The inscription ‘Since 1983, Limited Edition, N° XX/40’ in capital letters on the case back also signifies the limitation of the special edition. Since the 1980s, the methods of attaching the glass have evolved. Instead of a dovetail construction made of hardmetal, Rado now uses adhesives to attach the glass to the ceramic case.

The Rado Anatom Automatic with a green colour gradient (Ref. R10202319)

Within the new collection, only the limited edition with its black lacquered dial (Ref. R10201739) remains true to the original monochrome aesthetic. The dials of the other references are lacquered, polished, and have a horizontally satin-finished background. In addition, the dials showcase an individual colour gradient: green (Ref. R10202319), blue (Ref. R10202209), or cognac (Ref. R10202309) merge into black. The rhodium-coloured anchor symbol and the white or silver-coloured brand logo below 12 o’clock and the automatic or jubilé logo above 6 o’clock also adorn the dial. The hours, minutes, and seconds are indicated by three rhodium-plated hands with a white Super-LumiNova coating. The applied indices are also rhodium-plated and have a white Super-LumiNova coating. The indices of the limited edition, on the other hand, are formed by 11 baguette-cut diamonds. At 6 o’clock there is a date window instead of an index.

At the heart of all the timepieces beats the ultra-thin automatic calibre R766 with a power reserve of 72 hours. The high-precision calibre is equipped with an anti-magnetic Nivachron balance spring and its accuracy has been tested in five instead of three positions. Apart from using an automatic movement instead of a quartz movement, the structured rubber strap also represents an innovation in the Anatom collection. The characteristic horizontal stripes and shape have been retained, although with a more contemporary material. The rubber strap is complemented by a three-fold clasp made of brushed stainless steel and a cover made of (matt) black high-tech ceramic. Offering a sporty look, it provides customers with an additional strap option within the collection. The price for all standard versions of the new Anatom is 3,700 euros.

The Rado automatic calibre R766

This year, Rado is adding five more models to its Anatom collection, which was relaunched in 2023. These editions are complemented by a bracelet made of polished high-tech ceramic with stainless steel links, to which the 32.5 mm wide case tapers to a width of 20 mm. The additions include two versions in black ceramic, two Jubilé versions and one model in grey. Like the 2023 edition, they also feature the automatic calibre R766 with a 72-hour power reserve and are equipped with a date window at 6 o’clock and white Super-LumiNova.

On the dial of the black references, rhodium-coloured (Ref. R10201152) or yellow gold-coloured (Ref. R10200152) applied indices and hands provide a pop of colour. Matching these details, the stainless steel links of the black high-tech ceramic bracelet are either polished or have a yellow gold-coloured PVD coating. In contrast, the accents on the grey model (Ref. R10203102) are rose gold-coloured.

While the additionally polished dials of these three models feature a horizontal line pattern with irregular spaces, the black lacquered dials of the Jubilé editions are kept puristic. This draws the eye to the diamond indices at twelve, three and nine o’clock on both timepieces. In contrast to the Ref. R10201712, where the diamonds stand for themselves, the Ref. R10204712 features discreetly printed, matt black indices around the diamond positions. The latter model appears even more glamorous, as the black bracelet made of polished high-tech ceramic is set with diamonds. 38 sparkling gemstones can be found on the polished stainless steel end pieces and 124 can be seen on the first four links of the bracelet.

On all five models, the high-tech ceramic bracelets contribute to a harmonious overall look and a pleasantly light wear. Moreover, they emphasise the aesthetic diversity of the Anatom – from sporty to elegant.

Since the 1980s, the Anatom has traced Rado’s anatomy – from its product development to its corporate philosophy, which has been a guiding principle since the launch of the DiaStar in 1962: ‘If we can imagine it, we can make it. And if we can make it, we will.’ As we have seen, the original’s rectangular hardmetal case was a testament to the material developments of the time and Rado’s design language. At the same time, the Anatom‘s uniqueness did not only stem from its historical references, but from its contribution to Rado’s history with its own innovation: the convex sapphire crystal and its ergonomic feel. Similarly, the new Anatom models continue the original’s tradition of symbolising Rado’s anatomy and celebrating innovation beyond the movement. As Rado CEO Adrian Bosshard aptly summarises: ‘The timeless and unique design was and still is in keeping with the spirit of the times. All the watches in the collection are easily recognisable as Rado timepieces and have achieved cult status over time. The design of this model was decades ahead of the competition.’